Pipe-embedding type underfloor heating construction method capable of preventing ground cracks

A construction method and buried-pipe technology, which is applied to floors, heating methods, hot water central heating systems, etc., can solve arc-shaped cracks, uneven thermal expansion and contraction of surface concrete, affecting appearance and heating distribution and other problems to achieve the effect of uniform ground temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

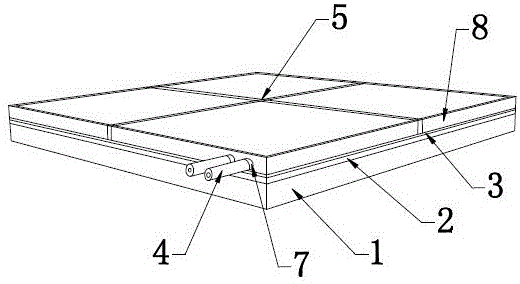

[0035] The buried pipe type floor heating construction method capable of preventing ground cracks provided by this embodiment comprises the following steps:

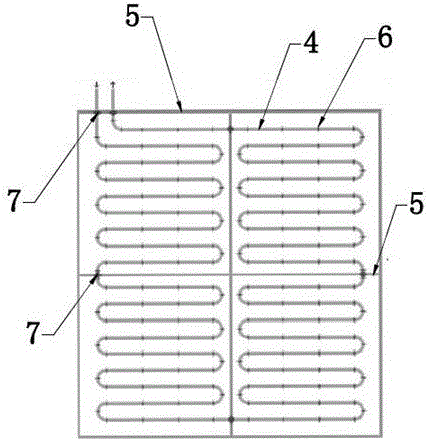

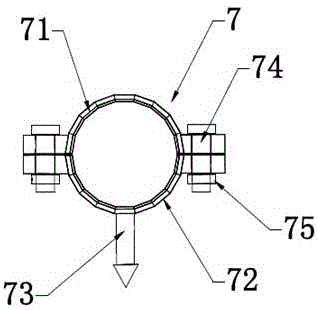

[0036] S1: Construction preparation; specifically, draw the plumbing pipeline layout according to the area to be laid on the site for floor heating (such as figure 2 shown), and plan the location and number of expansion joints. At the same time, prepare materials according to the above-mentioned layout plan and planned number of expansion joints; when drawing the plumbing pipeline layout, use expansion joint materials to divide the construction area into multiple sections. The pipelines in each section are arranged in an S-shape. The pipeline enters from one end of a column or row of sections on the left or right, and the other end protrudes into the adjacent section until the last column or row of sections is laid out. , exiting from the entrance in a straight line; the expansion joints are mainly composed of closed pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com