Installing method for whole-assembling scaffold cantilever

An installation method and a scaffolding technology, which are applied to the accessories of scaffolding, the scaffolding supported by the building structure, the supporting structure of the building, etc., can solve the problems of affecting the quality of the main body of the building, difficult to recycle U-shaped cards, and high labor intensity of workers, so as to save raw materials Low cost, easy rotation and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

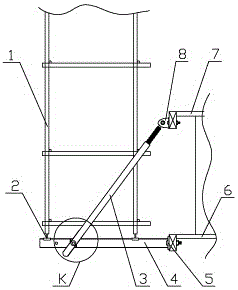

[0060] see Figure 1-Figure 13 , the present invention is a kind of installation method of fully assembled scaffold suspension, comprising the following steps:

[0061] Step 1: Make a fully assembled scaffold cantilever assembly according to the main structure of the building: including the cantilever beam fastening assembly 5 set on the shear wall or ring beam 6 of the nth floor of the building, and the I-beam cantilever beam of appropriate length 4. Diagonal tie rod fastening assembly 8, diagonal stay rod assembly 3 and scaffold pole positioning device 2 arranged on the outer concrete shear wall or ring beam of the main body 7 on the n+1st floor of the building;

[0062] The cantilever beam fastening assembly includes a base steel plate 15, a pre-embedded PVC sleeve A and a wall-through bolt A, the base steel plate and one end of the I-steel cantilever beam are welded together, and the upper and lower parts of one side of the base steel plate are respectively provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com