An automatic loading and unloading drill pipe device for a soft coal seam gas drilling rig and its application method

A soft coal seam, automatic loading and unloading technology, applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve problems such as waste of energy, unusable drilling, and collapse of the wall of the drilled hole, so as to reduce economic losses and improve Drilling efficiency, effect of reducing work requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

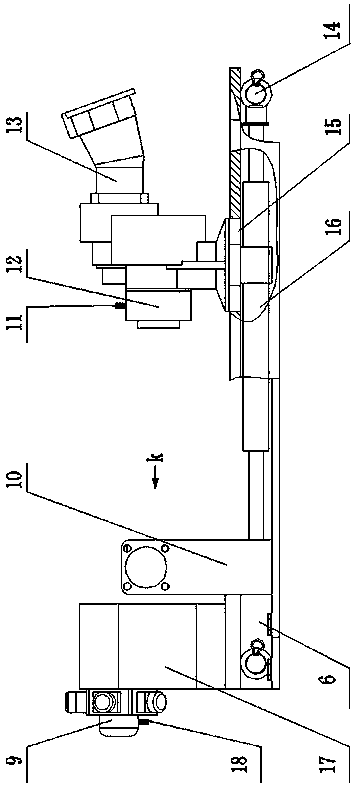

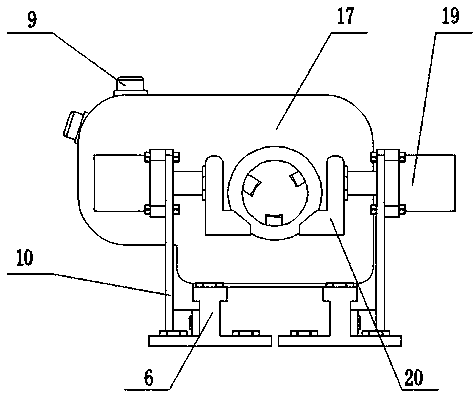

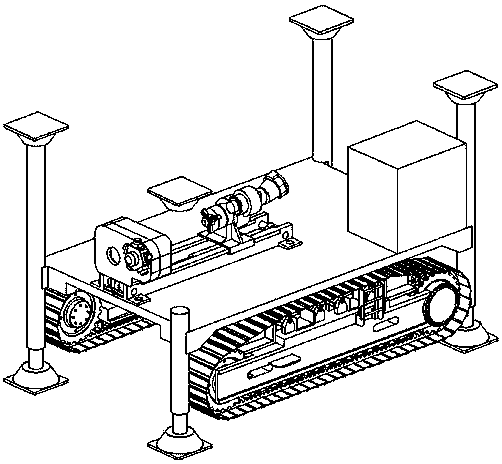

[0033] Such as Figure 1~4 As shown, an automatic loading and unloading drill pipe device for a soft coal seam gas drilling rig includes an auger drill pipe 1, a front power head 2 and a rear power head 3 of the drill pipe, a speed measuring device, a feeding device 6, a frame 7, and a frame 7 is surrounded by a hydraulic jacking column 4, the function of the hydraulic jacking column 4 is to tighten the roadway when the drilling rig is working to ensure its stability; the middle part of the upper surface of the frame 7 is provided with a feeding device 6, including guide rails and feeding hydraulic cylinders 16 The rear of the frame 7 sides is provided with a hydraulic power unit 5, including a motor pump group, an oil tank, and the bottom of the frame 7 is a crawler walking device 8, and the crawler belt is convenient to transfer the drilling rig downhole; the speed measuring device includes a speed sensor; The front power head 2 and the rear power head 3 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com