A Shallow Casing Leakage External Reinforcing and Repairing Technology

A process and casing leakage technology, which is applied in the field of external reinforcement and repairing of shallow casing leakage, can solve the problems of affecting the construction of drilling plugs, poor compression resistance, and reduction of casing inner diameter, so as to avoid casing damage and leakage, and apply Broad prospects and good restoration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

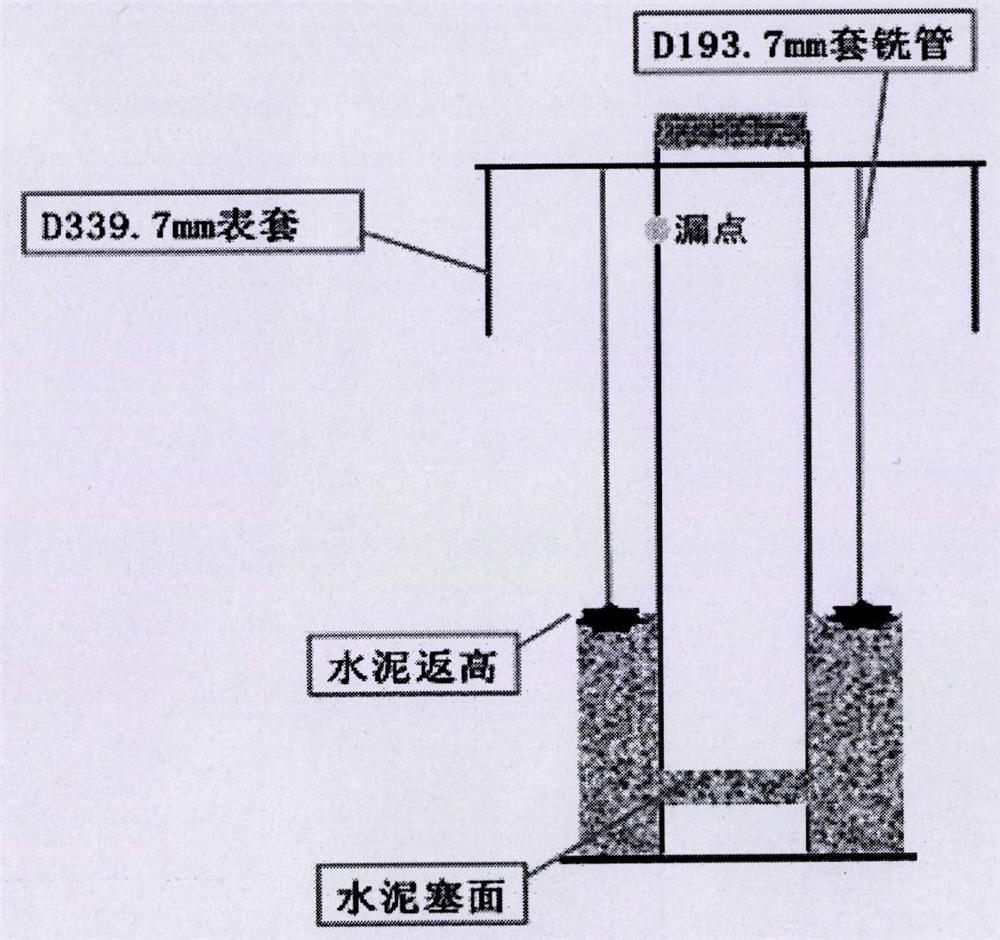

[0008] Example 1: Put a cement plug at 400m below the leakage point of the casing. During plugging construction, cut the ring-shaped steel plate, pour out the upper casing of the oil layer, and select the D230mm casing milling head + D193.7mm casing milling pipe casing milling to the cement 15m below the return height, during the casing milling construction process, the casing milling pipe is 5m scribing movable, and the anti-jacking block is welded at the thread button of the casing milling pipe to prevent the casing milling torque from being too large, causing the casing milling pipe thread to stick. The casing milling depth is determined comprehensively based on the height return depth and casing milling conditions to prevent the influence of the original cementing slurry mixing zone. The casing milling head is replaced in time according to the casing milling situation. After casing milling reaches the target depth, the last casing milling pipe is placed on the plane Sleeve ...

Embodiment 2

[0010] Put a cement plug at 500m below the leakage point of the casing. During plugging construction, cut the annular steel plate, pour out the upper casing of the oil layer, and select the D230mm casing milling head + D193.7mm casing milling pipe casing milling to 20m below the cement return height. , during the casing milling construction process, the casing milling 10m movable casing milling pipe is used, and the anti-top block is welded at the threaded thread of the casing milling pipe to prevent the casing milling torque from being too large, causing the casing milling pipe thread to stick. Comprehensively determine the casing milling depth based on casing milling conditions to prevent the influence of the original cementing slurry mixing zone, replace the casing milling head in time according to the casing milling situation, and casing mill the upper plane of the last casing milling pipe to the target depth after casing milling. Ground depth, reverse the square drill, low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com