Soft and hard sealing barrier method for coal mine underground oxygen-free tunneling working surface

A technology for excavating working faces and coal mines, which is applied in the ventilation of mines/tunnels, mining devices, mining equipment, etc. It can solve the problem that the barrier effect cannot reach the anaerobic working face, etc., so as to reduce the time for stopping production and control the gas, and eliminate the gas. The effect of burning and explosion, increasing the speed of the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

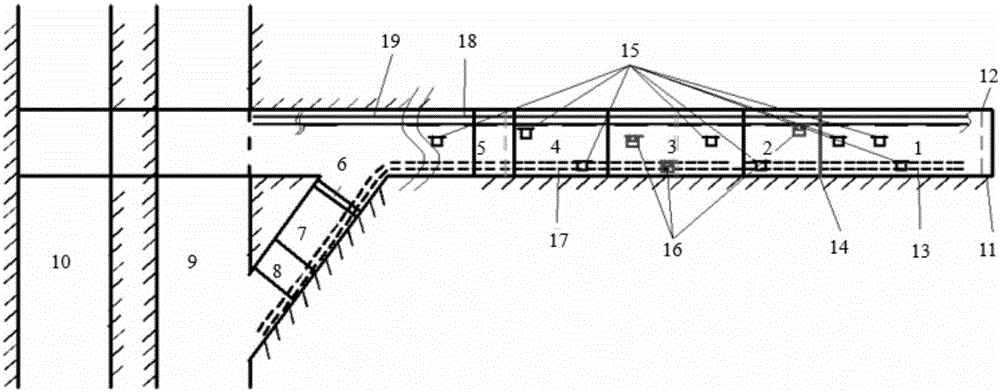

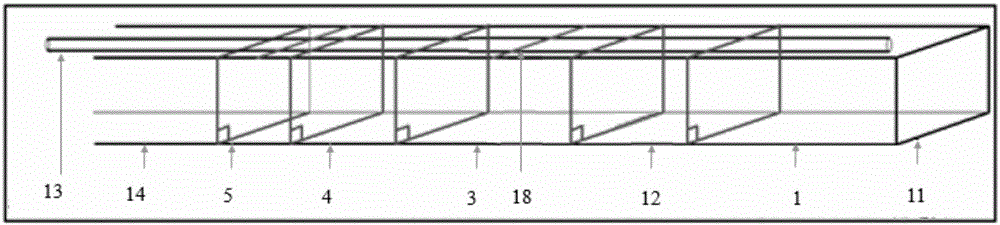

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0019] The invention provides a soft and hard sealing barrier method for an anaerobic driving face in an underground coal mine.

[0020] This method isolates the external air from the tunneling gas through the hard barrier system, soft barrier system, intelligent dynamic drainage system and monitoring system to achieve no oxidation in the tunneling roadway; the hard barrier system includes dampers, tapes, and sealing strips , there are five dampers, such as figure 1 , figure 2 As shown, five dampers 14 divide the tunneling roadway 17 into six areas, which are: high-concentration gas drainage area 1, leakage buffer area 2, nitrogen curtain barrier area 3, effect monitoring area 4, positive pressure emergency area 5 and Nitrogen area 6; the soft barrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com