Urea solution supply system and method used for SCR (selective catalytic reduction) system anti-crystallization and pump suction unit

A solution supply and pumping technology, applied in engine components, exhaust treatment, mechanical equipment, etc., can solve problems such as clogging and reduce the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

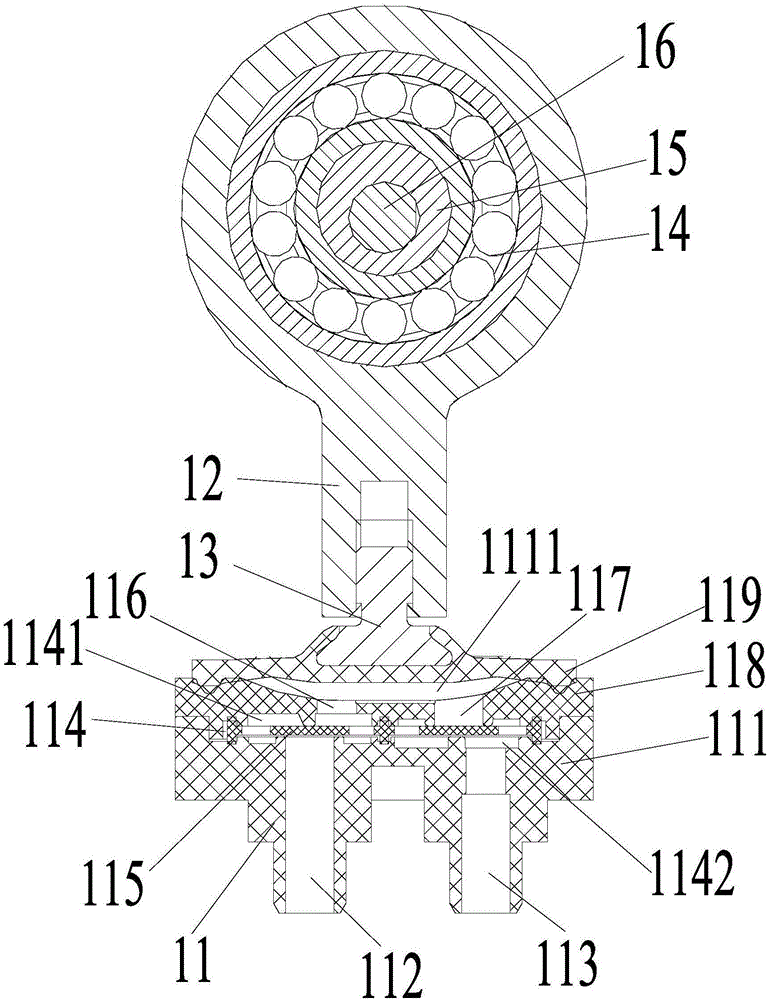

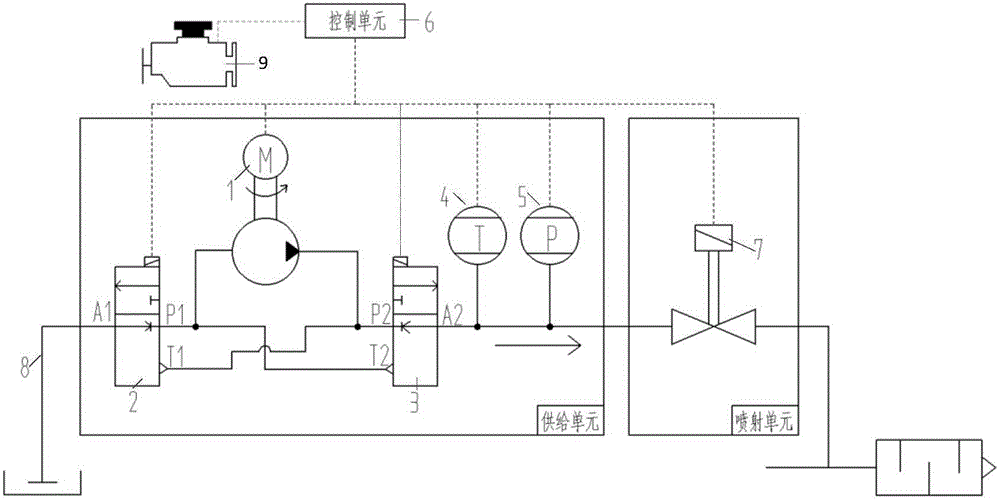

[0035] Please refer to figure 1 , the present invention provides a pumping unit 1 for absorbing urea solution, temporarily storing urea solution and discharging urea solution, including interconnected pumping check valves 11 and driving pumping check valves in order from bottom to top 11 working drive units.

[0036]The pumping check valve 11 is composed of a check valve upper body 118 and a check valve lower body 111. The end of the check valve lower body 111 away from the check valve upper body 118 is provided with a first liquid inlet communicating with the outside world. hole 112 and the first liquid outlet hole 113, the end of the check valve upper body 118 away from the check valve lower body 111 is provided with a hydraulic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com