Cylinder body press-fitted with piston cooling nozzle

A piston cooling nozzle and cylinder block technology, applied in liquid cooling, engine cooling, cylinder, etc., can solve the problems of potential safety hazards, large installation space, high manufacturing cost, etc., to save assembly time, increase motion radius, and spray position effective guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

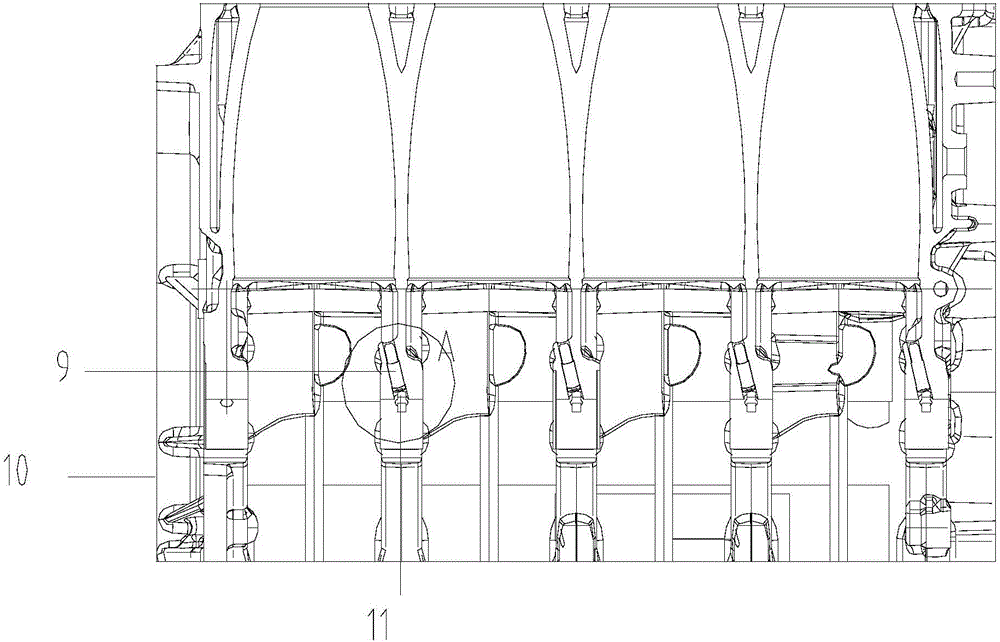

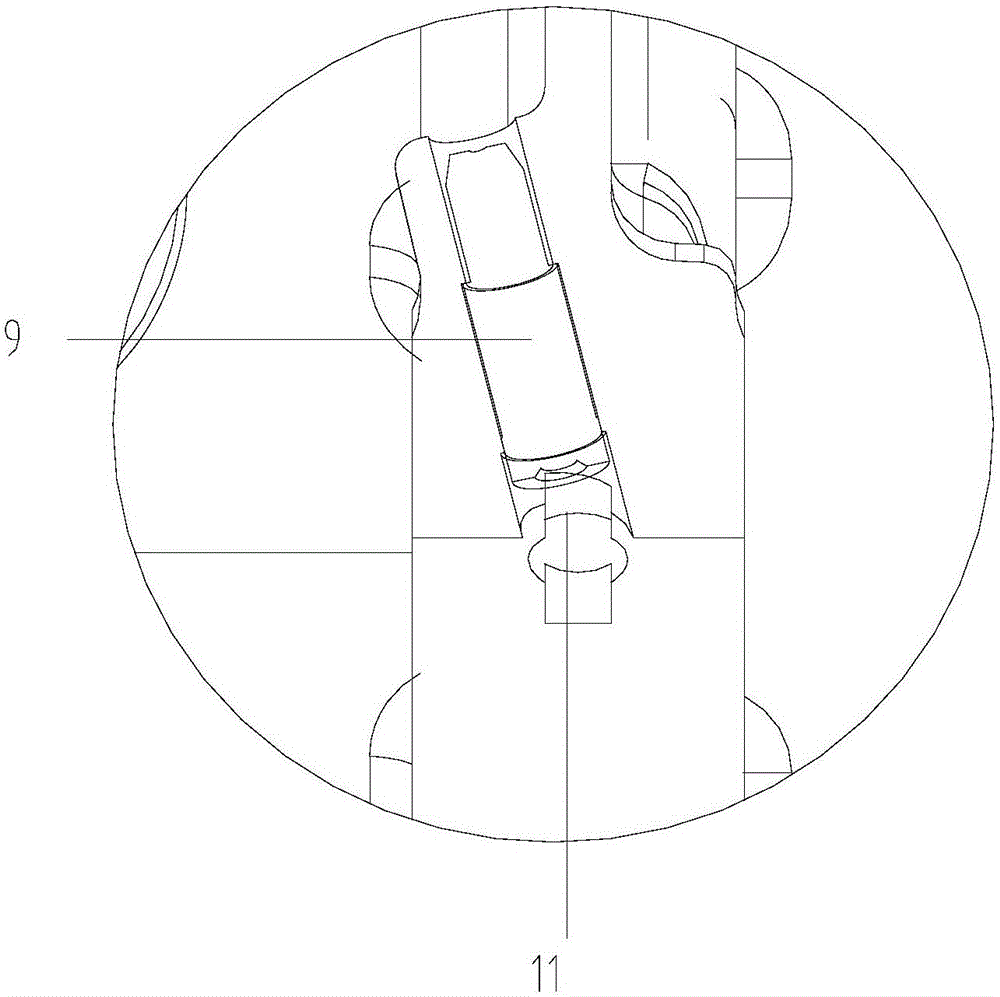

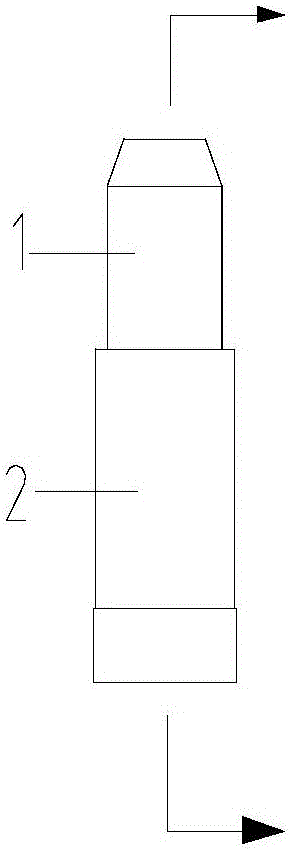

[0020] figure 2 for figure 1 Enlarged view of Part A of ; image 3 Schematic diagram of the structure of the piston cooling nozzle; Figure 4 for image 3 A-A sectional view of A-A, as shown in the figure: a cylinder block of a press-fitted piston cooling nozzle in this embodiment, the piston cooling nozzle 9 is press-fitted on the cylinder block 10 in a manner that can be sprayed on the exhaust side of the bottom of the piston The piston cooling nozzle 9 is press-fitted in the crankshaft hole of the cylinder block 10 to save the assembly time of the piston cooling nozzle 9 .

[0021] In this embodiment, a mounting hole 11 is provided on the main bearing seat of the cylinder block 10, and the piston cooling nozzle 9 is integrally press-fitted into the mounting hole 11; it is equivalent to press-fitting the piston cooling nozzle 9 into the crankshaft hole as a whole. , increasing the radius of motion of the crank linkage mechanism; the injection position is more effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com