Floating airbag of aerial wind driven generator

A technology of wind turbines and airbags, which is applied in the control of wind turbines, the combination of wind turbines and wind motors, etc. It can solve problems such as difficult adjustment and control of stagnant equipment, reduction of power generation efficiency and safety, rapid fall, etc., and achieve space The position is easy to control, the power generation equipment is protected, and the effect of wind speed and direction changes is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

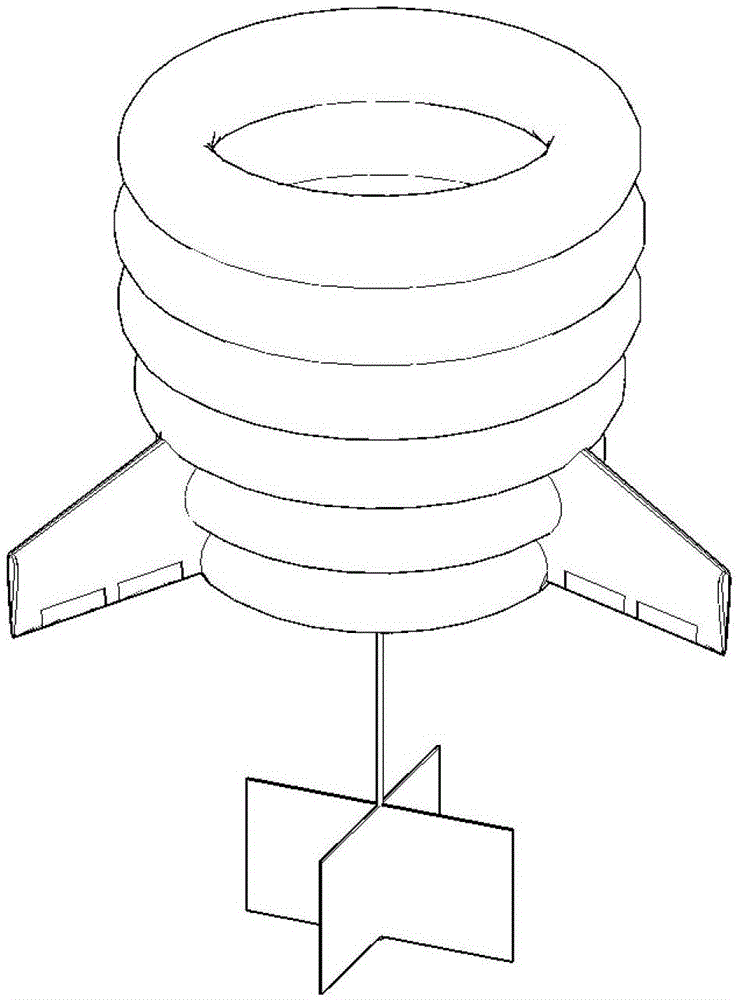

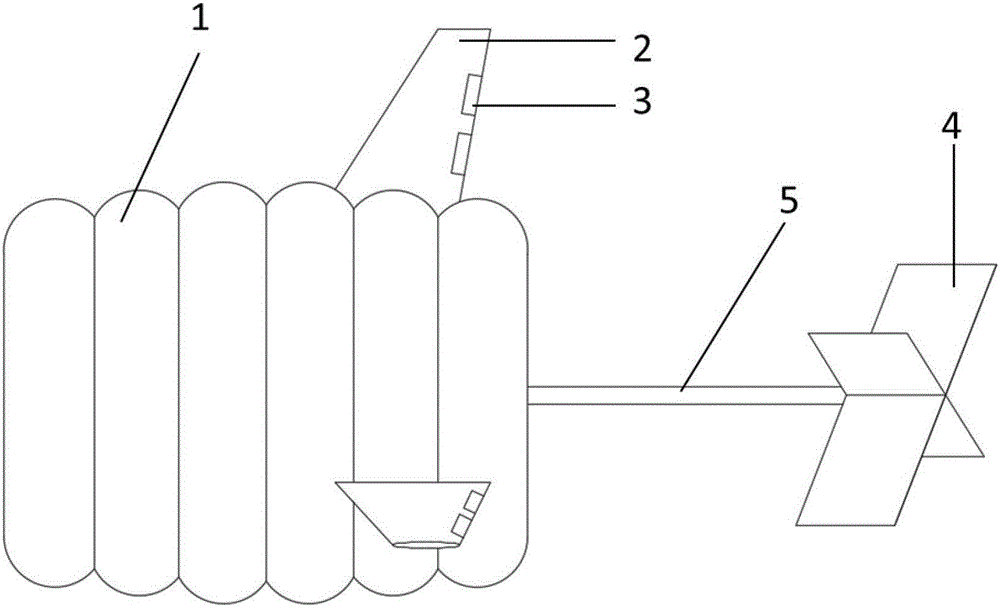

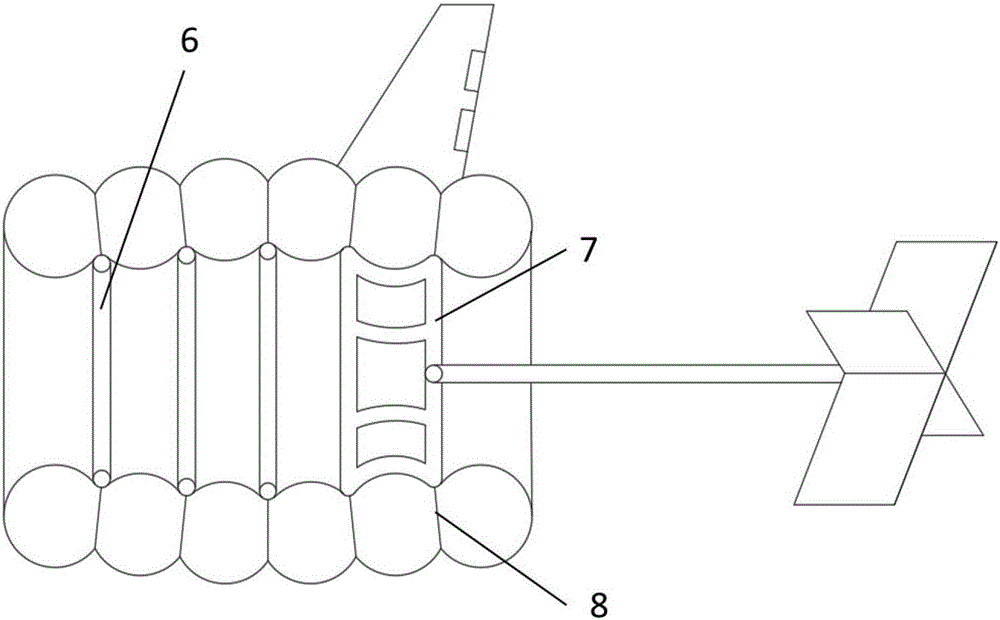

[0023] Six independent ring-shaped helium airbags of different sizes provide full lift, and the independent airbags can effectively reduce the impact caused by airbag damage. The carbon fiber frame structure inside the airbag has two structural forms, one is an independent ring-shaped empty tube structure, and the other is a platform-shaped carbon fiber frame structure, which is used to connect the cross tail rudder plate. The three tail fins are connected to the airbag at intervals of 120°. Each tail fin is equipped with two rudders, which are controlled by stepping motors. With the help of wind force and rudders, the fan is always facing the windward direction. The cross tail rudder plate is connected to the platform-shaped carbon fiber frame inside the airbag by a hydraulic telescopic rod, and undertakes the main direction control task. By controlling the length change of the hydraulic telescopic rod, the front and rear center of gravity of the high-altitude wind turbine ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com