Tank heat exchanger for heat pump system

A heat pump system and heat exchanger technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve problems such as poor anti-freezing ability, low heat exchange efficiency, complex structure and control system, and achieve Low cost, high heat exchange efficiency, easy maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

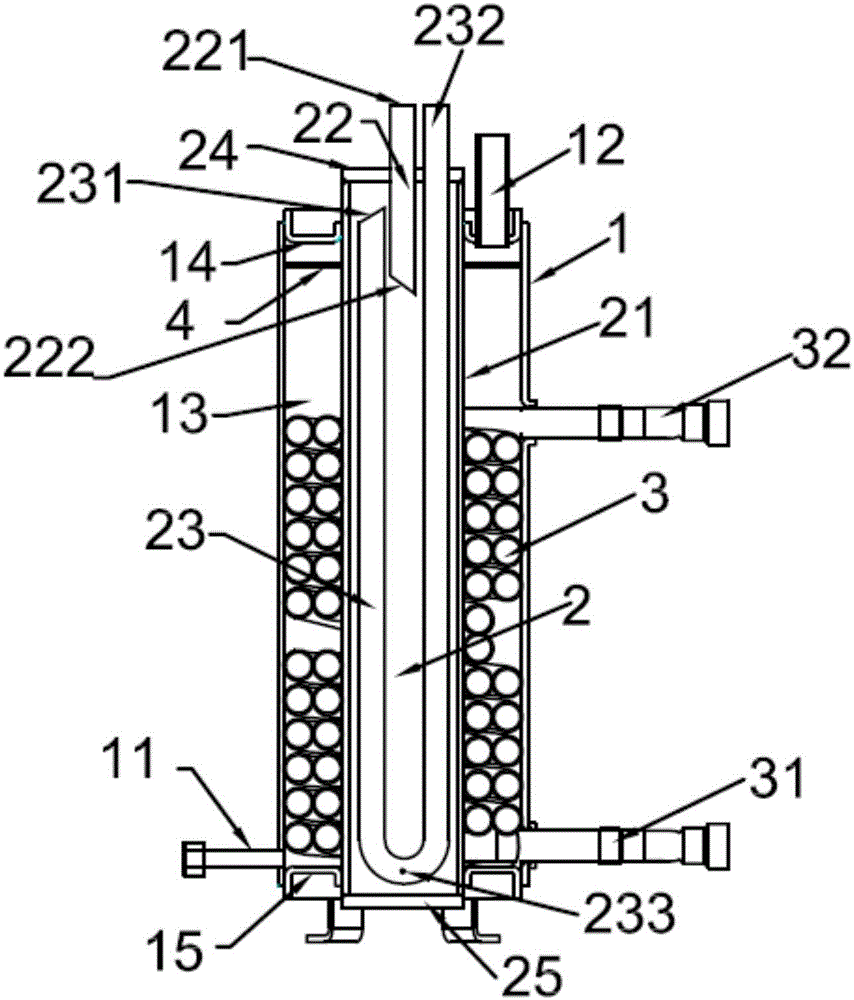

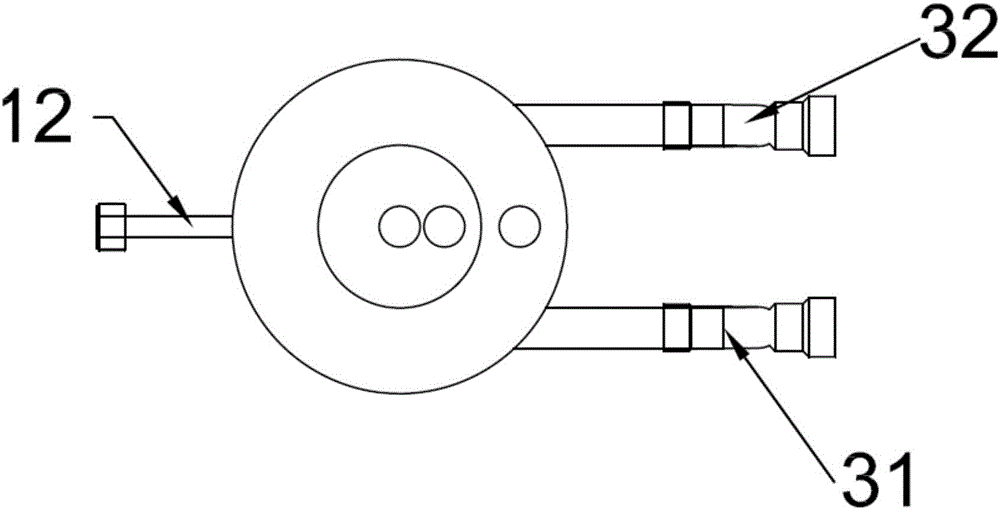

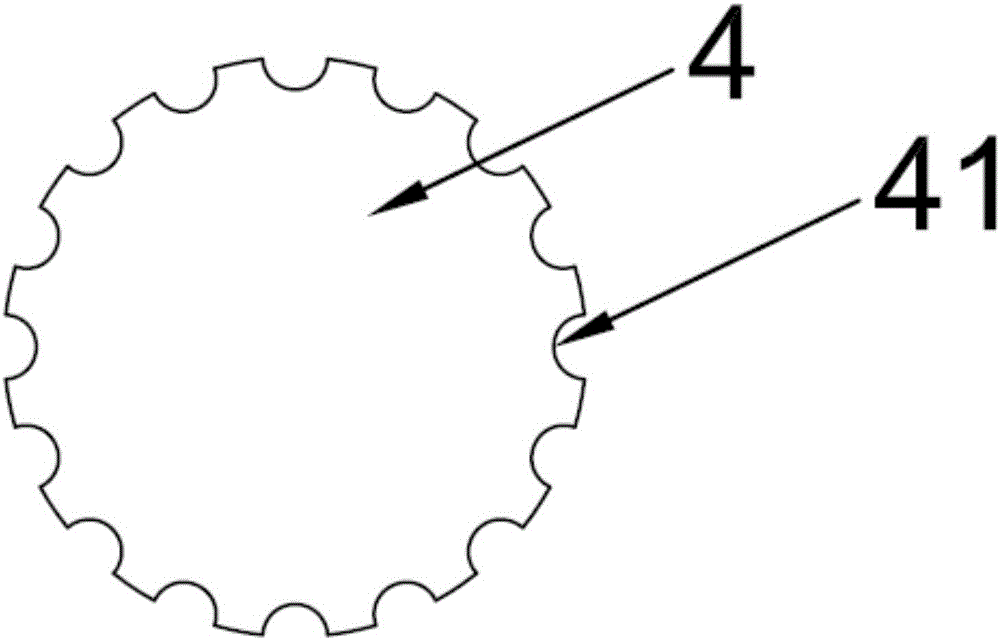

[0026] Example: such as Figure 1-3 As shown, a tank heat exchanger for a heat pump system includes: an outer cylinder body 1, the top and bottom of the outer cylinder body are respectively provided with an upper cover plate 14 and a lower cover plate 15, and the outer cylinder body 1 A refrigerant inlet 11 is provided at the bottom of the upper cover, and a refrigerant outlet 12 is provided on the upper cover; a gas-liquid separator 2, the gas-liquid separator includes an inner cylinder 21, and the top and bottom of the inner cylinder are respectively provided with There are an upper sealing plate 24 and a lower sealing plate 25, the upper sealing plate 24 is provided with an air inlet pipe 22 and an air outlet pipe 23; Between, the heat exchange tube is spirally coiled outside the inner cylinder, the upper end and the lower end of the heat exchange tube are respectively provided with a water outlet 32 and a water inlet 31; a baffle 4, the baffle 4 is arranged on the Below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com