Fish skin antifreeze protein as well as preparation method and application thereof

A technology of antifreeze protein and fish skin, which is applied in the fields of application, freezing sweets, and chemical preservation of meat/fish, etc., to achieve good antifreeze function, improve antifreeze ability, and improve the effect of tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

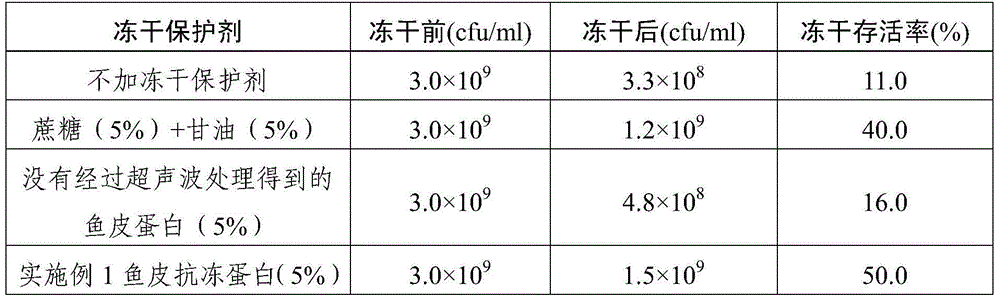

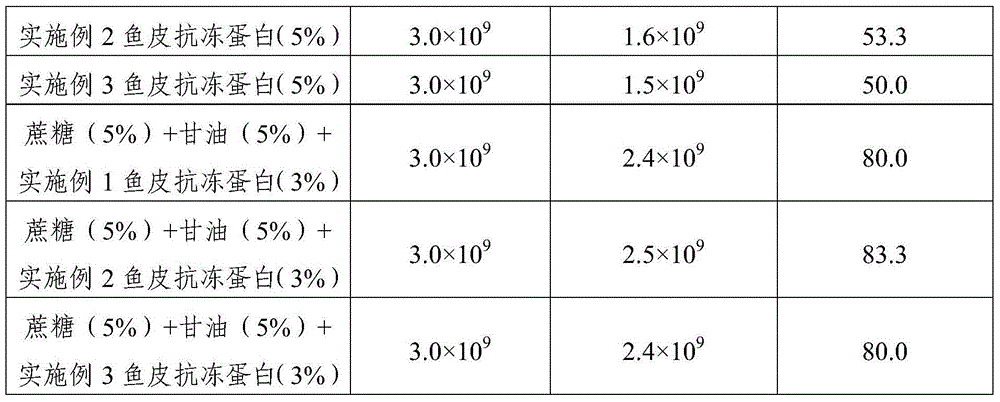

Embodiment 1

[0072] Embodiment 1: the preparation method of grass carp skin antifreeze protein

[0073] (1) Choose 100 grams of frozen grass carp skin, thaw it at 7°C for 12 hours, wash the fish skin with clean water that meets the drinking water hygiene standard, and the cleaning water temperature is 10°C; The fish skin is beaten into a slurry; then 150 grams of water 1.5 times the weight of the fish skin slurry is added to the beaten fish skin slurry, and the fish skin slurry is ground into a fish skin slurry by a colloid mill, and the upper layer of fat is removed by centrifugation at 6000g for 8 minutes to obtain fat-free fish skin Serum 245 grams.

[0074] (2) The degreased fish skin slurry obtained in step (1) was placed in an ultrasonic generator, and subjected to ultrasonic treatment with a power of 800w and a frequency of 25KHz for 10 minutes to change the tissue structure of the fish skin protein.

[0075] (3) according to the ratio of weight percent of fish skin weight 0.2%, ad...

Embodiment 2

[0079] Embodiment 2: the preparation method of cod skin antifreeze protein

[0080] (1) Choose 200 grams of frozen cod skin, thaw it at 7°C for 10 hours, wash the fish skin with clean water that meets drinking water hygiene standards, and the cleaning water temperature is 10°C; Beat the fish skin into a slurry; then add 200 grams of water 1.0 times the weight of the fish skin slurry to the beaten fish skin slurry, use a colloid mill to grind the fish skin slurry, and centrifuge at 5000g for 12 minutes to remove the upper layer of fat to obtain fat-free fish skin Serum 388 grams.

[0081] (2) Place the degreased fish skin slurry obtained in step (1) in an ultrasonic generator, and undergo ultrasonic treatment with a power of 900w and a frequency of 20KHz for 15 minutes to change the tissue structure of the fish skin protein.

[0082] (3) according to the ratio of weight percent of 0.3% of fish skin weight, add composite protease 0.6 gram in the degreased fish skin slurry after...

Embodiment 3

[0086] Embodiment 3: the preparation method of tilapia fish skin antifreeze protein

[0087] (1) Choose 100 grams of frozen tilapia fish skin, thaw it at 7°C for 15 hours, wash the fish skin with clean water that meets the drinking water hygiene standard, and the cleaning water temperature is 10°C; The machine beats the fish skin into a slurry; then add 300 grams of water 3.0 times the weight of the fish skin slurry to the beaten fish skin slurry, use a colloid mill to grind the fish skin slurry, and centrifuge at 4000g for 12 minutes to remove the upper layer of fat to obtain fat-free Fish skin slurry 390g.

[0088] (2) Place the degreased fish skin slurry obtained in step (1) in an ultrasonic generator, and undergo ultrasonic treatment with a power of 1000w and a frequency of 25KHz for 10 minutes to change the tissue structure of the fish skin protein.

[0089] (3) add composite protease 0.5 gram in the degreased fish skin slurry after step (2) ultrasonic treatment accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com