A kind of biological preservative for shrimp meat and its application

A technology of biological preservatives and shrimp meat, applied in food science, using chemicals to preserve meat/fish, food ingredients as antioxidants, etc., can solve the problems of no biological preservatives for shrimp meat, etc., achieve significant freshness preservation effect, no chemical Residue, good anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

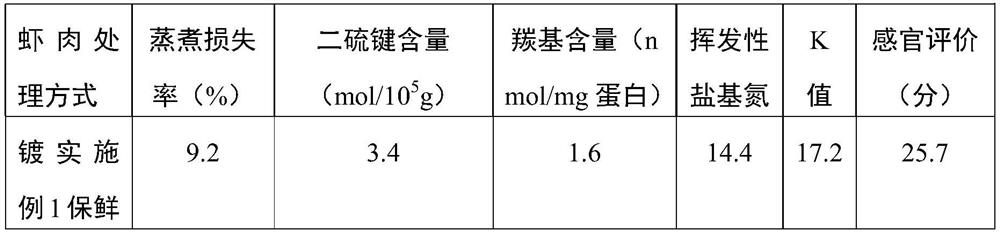

Embodiment 1

[0044] Preparation and Application of Embodiment 1 Shrimp Biological Preservative (1)

[0045] (1) Choose 100 grams of frozen red shrimp heads, thaw and wash them at 10°C, wash the shrimp heads with clean water that meets the drinking water hygiene standards, and beat the shrimp heads with a beater after cleaning the shrimp heads, and add the shrimp heads 2.5 times the weight of water was boiled at 121°C for 180 minutes.

[0046] (2) Add compound protease to the cooking liquid in step (1) according to the weight percentage ratio of 0.2% of the shrimp head weight and carry out step-by-step enzymolysis:

[0047] The first step uses 0.1% protease (alkaline protease and papain), the mass ratio between them is 1:1), and the enzymolysis reaction is carried out at 55°C for 1.5h;

[0048] Then carry out the second step and use 0.1% compound protease (neutral protease and flavor protease) composition, the mass ratio between them is 1:1), carry out enzymolysis reaction 2.0h under the c...

Embodiment 2

[0051] Preparation and Application of Embodiment 2 Shrimp Biological Preservative (2)

[0052] (1) Choose 500 grams of frozen red shrimp heads, thaw and wash them at 6°C, wash the shrimp heads with clean water that meets the drinking water hygiene standards, and beat the shrimp heads with a beater after cleaning the shrimp heads, and add the shrimp heads 3.0 times the weight of water was boiled at 115°C for 200 minutes.

[0053] (2) add compound protease in (1) according to the percentage by weight of shrimp head weight 0.25% and carry out enzymolysis step by step:

[0054] The first step uses 0.15% protease (alkaline protease and papain), the mass ratio between them is 1:2), and the enzymolysis reaction is carried out at 60°C for 1.0h;

[0055] Then carry out the second step and use 0.1% compound protease (neutral protease and flavor protease) composition, the mass ratio between them is 1:1), carry out enzymolysis reaction 2.0h under the condition of 55 ℃; Incubate at 98 ℃ f...

Embodiment 3

[0058] Preparation and Application of Embodiment 3 Shrimp Biological Preservative (3)

[0059] (1) Choose 1000 grams of frozen red shrimp heads, thaw and wash them at 10°C, wash the shrimp heads with clean water that meets the drinking water hygiene standards, and beat the shrimp heads with a beater after cleaning the shrimp heads, and add the shrimp heads 3.5 times the weight of water was boiled at 121°C for 180 minutes.

[0060] (2) add compound protease in (1) according to the percentage by weight of shrimp head weight 0.3% and carry out enzymolysis step by step:

[0061] The first step uses 0.15% protease (alkaline protease and papain), the mass ratio between them is 1:2), and the enzymolysis reaction is carried out at 60°C for 1.0h;

[0062] Then proceed to the second step using 0.15% compound protease (neutral protease and flavor protease), the mass ratio between them is 1:1), and carry out the enzymolysis reaction at 55°C for 1.0h; incubate at 98°C for 10 minutes, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com