Feed drying and recovery device

A recycling device and collection device technology, applied in the directions of dry solid materials, dry goods processing, lighting and heating equipment, etc., can solve the problems of inconsistent drying time of feed, inability to achieve uniform drying, and inability to collect feed at the same time, and reduce labor costs. Operation steps, reduce manual operations, and simplify the effect of the collection and bagging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific implementations:

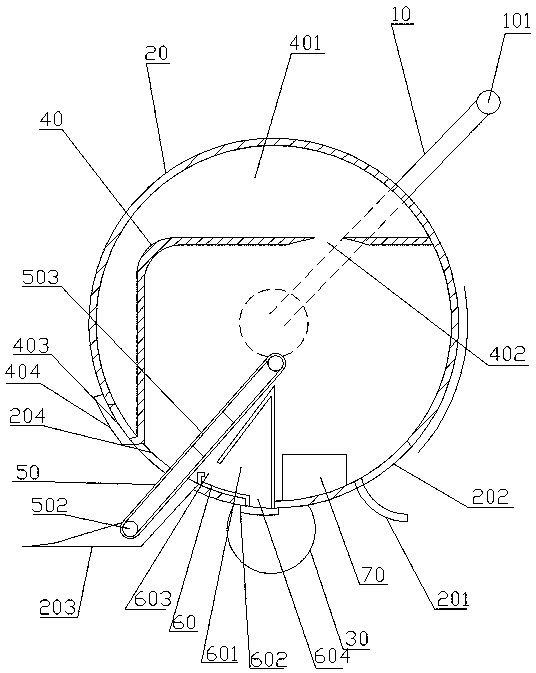

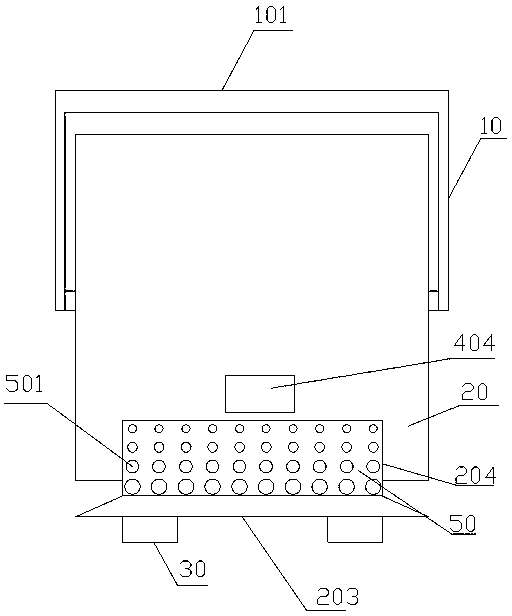

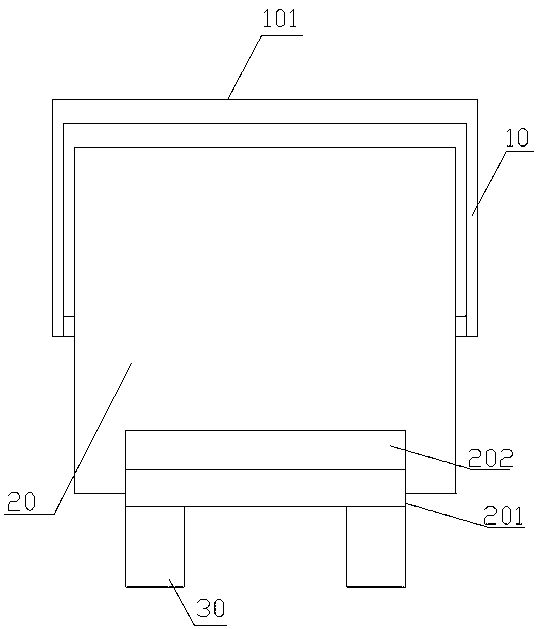

[0019] The reference signs in the drawings of the specification include: frame 10, handle 101, turning barrel 20, discharging plate 201, first discharging port 202, shoveling plate 203, first feeding port 204, roller 30, A collection device 40, a first containing cavity 401, a second inlet 402, a second outlet 403, a second baffle 404, a transmission belt 50, a leak 501, a transmission shaft 502, a vibrator 503, a second The collecting device 60, the second containing cavity 601, the first baffle 602, the third feed port 603, the third feed port 604, and the blower 70.

[0020] The embodiment is basically as attached figure 1 , Attached figure 2 And image 3 Shown: a feed drying and recycling device, including a frame 10, a motor, a roller 30, a turning cylinder 20, a first collection device 40, a second collection device 60, a handle 101, a transmission belt 50 and a blower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com