Explosion switch based on multi-side energy collecting jet flow

An energy-gathering jet and energy-gathering technology, which is applied in the field of electrical switches, can solve the problems of weakening the mechanical properties of the switch and the low utilization rate of explosive energy, and achieves the effects of preventing re-breakdown, improving safety, and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

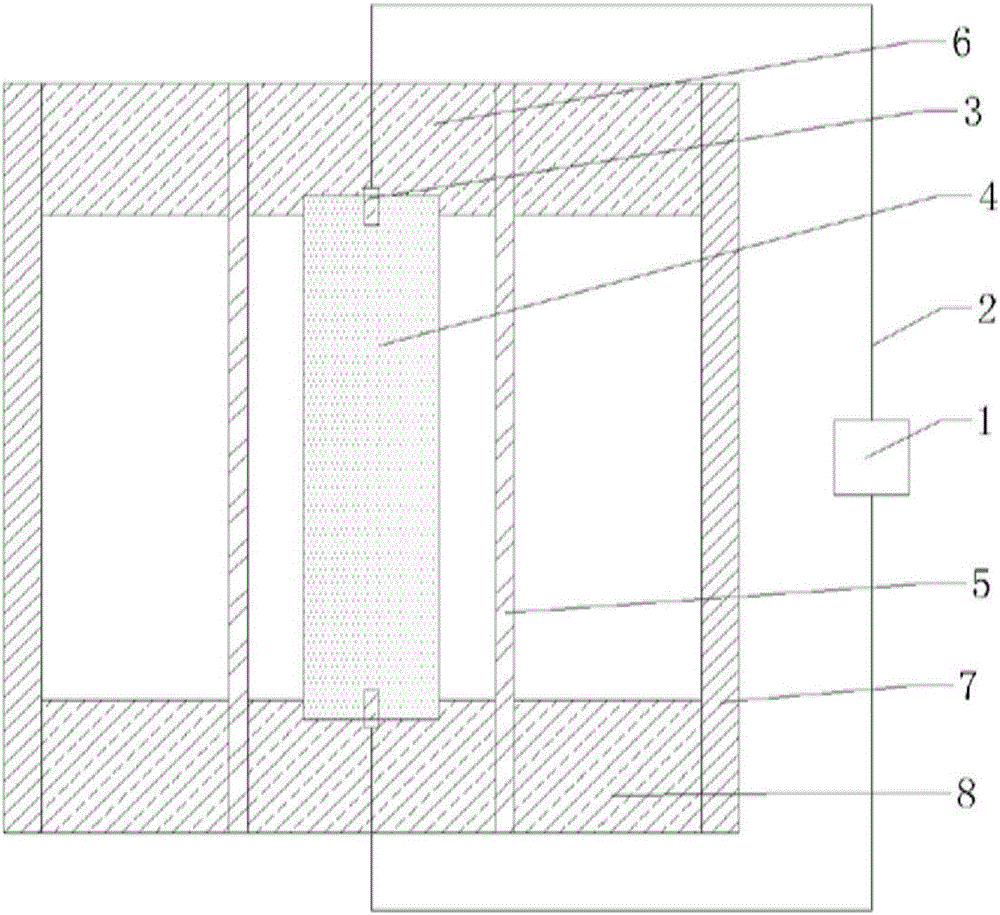

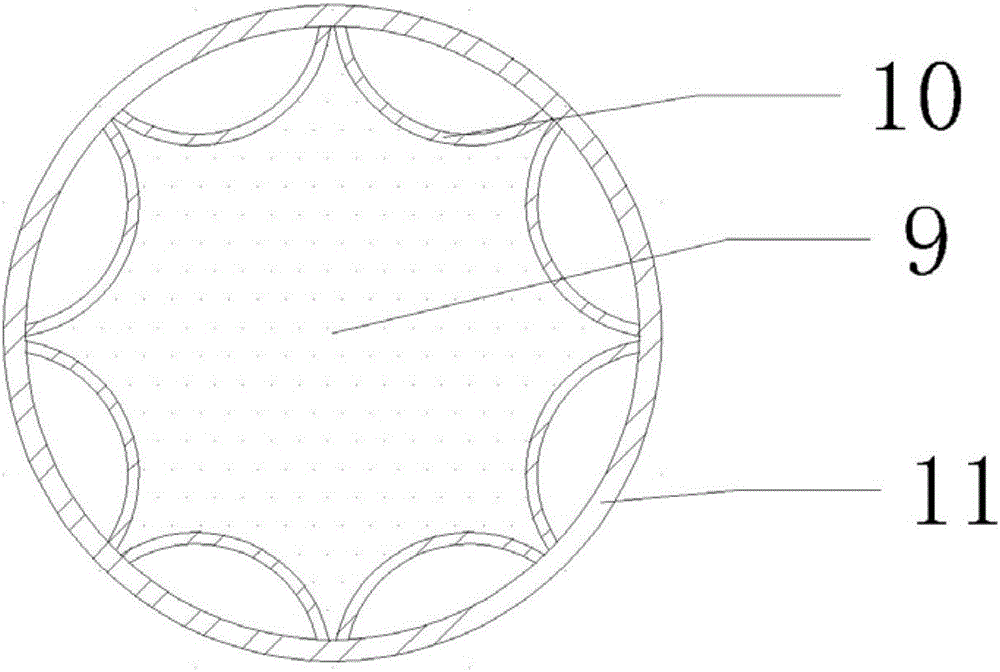

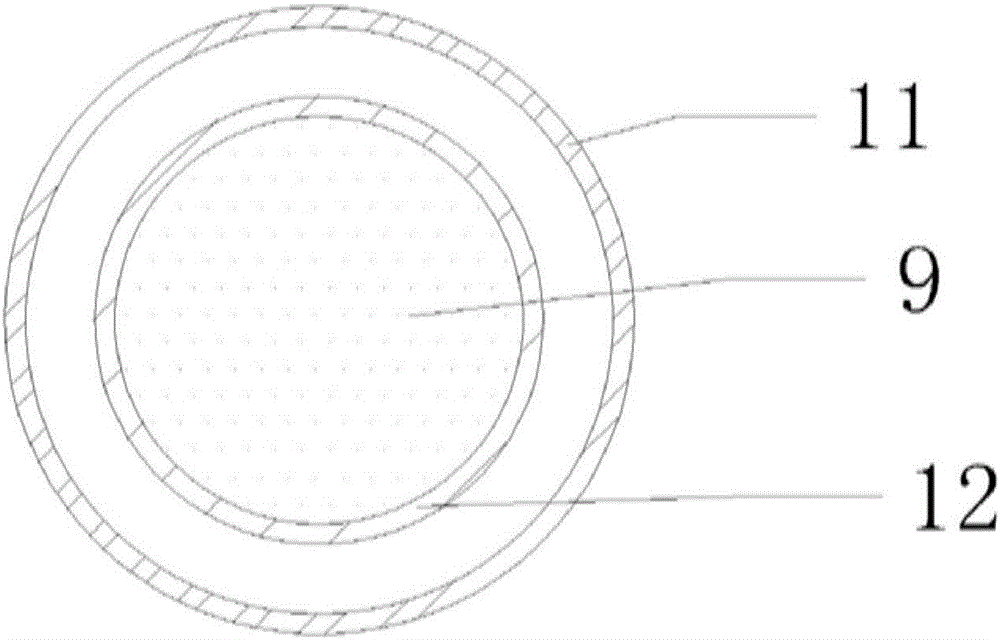

[0025] Such as figure 1 Shown, a kind of explosion switch based on multi-faceted concentrated energy jet, outermost layer is protective cylinder (7), and size is: wall thickness 1cm, height 20cm, internal diameter is 24cm, and material is high-strength epoxy. A protective end cover (8) with a wall thickness of 2cm is provided on its upper and lower sides, and its outer side and the protective cylinder (7) are fixed with bolts, and a through hole with an inner diameter of 8.4cm is opened in the center, and is fitted through an interference fit. Fix with the upper and lower two ends of the conductor (5) respectively. The shape of the conductor (5) is a round tube, the size is: inner diameter 8cm, wall thickness 0.3cm, height 20cm, and the material is red copper. Conductor end caps (6) with a diameter of 8.2 are arranged on the inner side of the conductor (5) at the upper and lower ends, and are connected with the conductor (5) through interference fit. There is a through hole ...

Embodiment 2

[0027] The difference from Example 1 is that both the annular energy-shaping charge cover and the axial energy-shaping charge cover in the multi-faceted circumferential energy-shaping charge pack adopt tapered drug-form covers in cross-section, wherein the axial shape-forming charge The cover cone angle is 60 degrees, and two adjacent drug-shaped covers are tangent at the inner wall of the shell. The cone angle of the circumferential energy-concentrating drug-shaped cover is also 60 degrees, and the distance between the opening ends is 2 cm.

[0028] The basic working process of the present invention is:

[0029] When the circuit needs to be disconnected, the explosive is detonated from the two ends and spreads to the center. Under the action of strong explosion pressure, the axial shaped charge cover is crushed and 8 "jet knives" are formed along the axial direction, and the conductor There are 8 pieces along the axial direction. When the detonation wave at the two ends reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com