Tapered roller bearing ring height difference measurement device

A tapered roller bearing and measuring device technology, applied in the direction of mechanical thickness measurement, etc., can solve the problems of many measuring links, low measuring efficiency, unsuitable for mass production, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

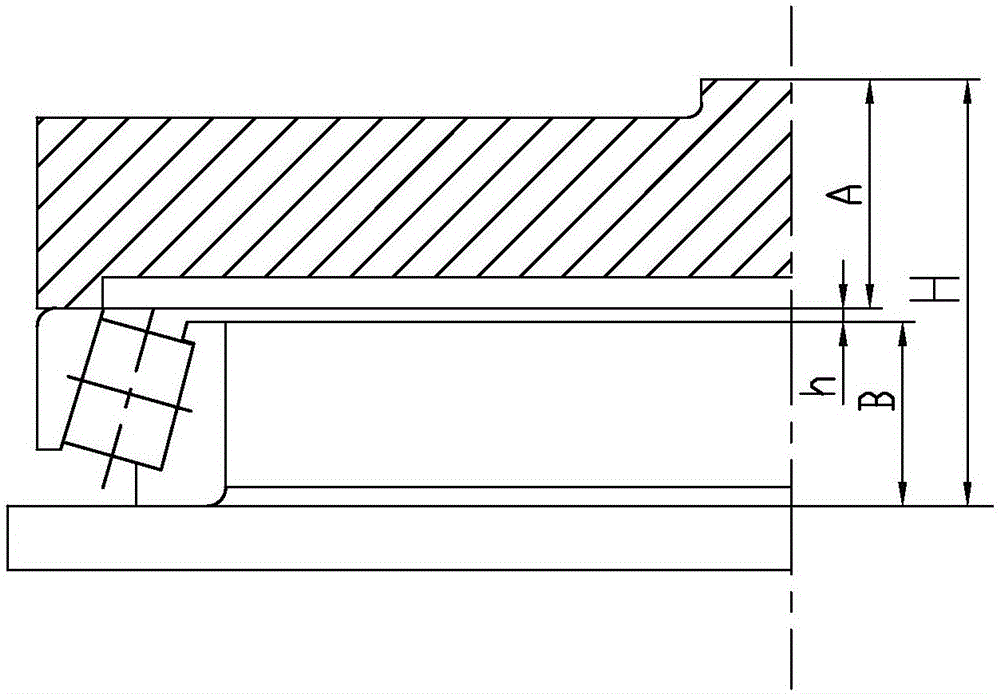

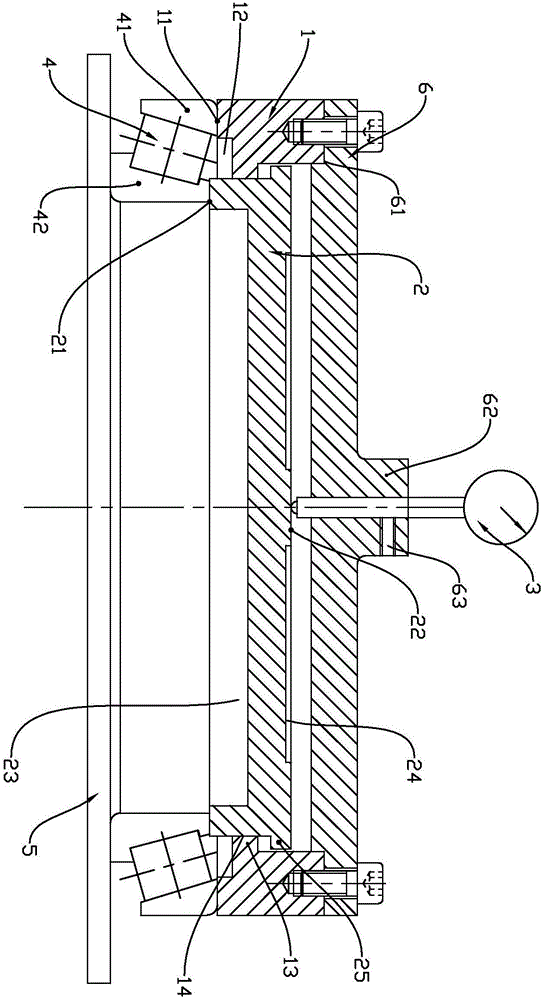

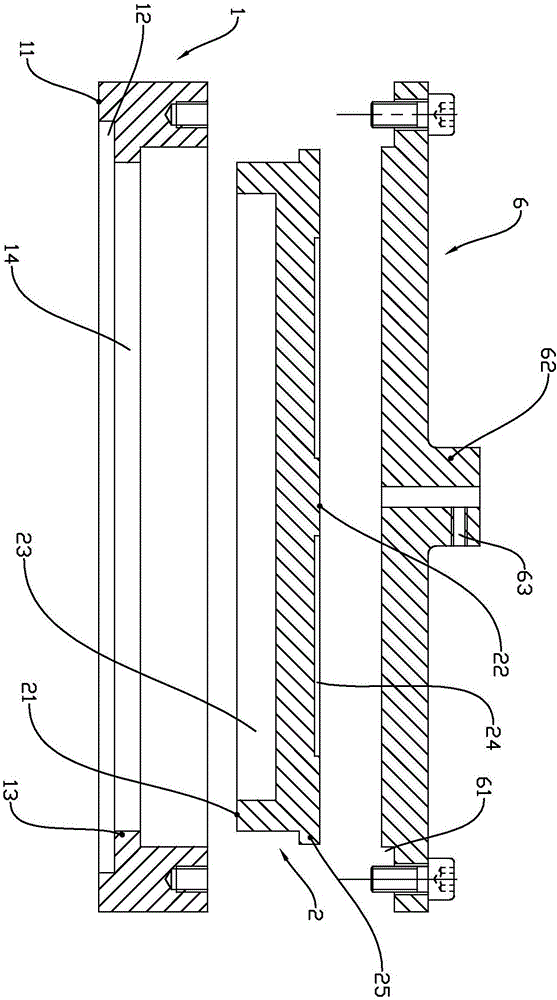

[0022] See attached figure 2 and image 3 , a tapered roller bearing ring height difference measuring device disclosed in the present invention includes a pressure plate and a measuring gauge 3. The pressure plate includes an annular outer ring pressure sleeve 1 and an inner ring pressure plate 2. The outer ring pressure sleeve 1 One end in the axial direction is pressed against the outer ring 41 of the bearing. This end of the outer ring pressure sleeve 1 is called the pressure end 11. The outer ring pressure sleeve 1 is provided with a fixed cover plate 6. The inner ring pressure plate 2 can be moved along the outer ring. The ring pressure sleeve 1 is fitted in the outer ring pressure sleeve 1 in the way of axial guide sliding, and the axial end of the inner ring pressure plate 2 is pressed against the bearing inner ring 42, and the end of the inner ring pressure plate 2 is connected with the outer ring pressure sleeve 1. The upper pressing end 11 is in the same direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com