Background noise energy eliminating measurement method of reverberation time of factory building

A technology of background noise and reverberation time, which is used in the measurement of reverberation time, measurement devices, and measurement of ultrasonic/sonic/infrasonic waves, etc. It can solve the problems that auxiliary equipment cannot be turned off, cannot be eliminated, and strong background interference noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

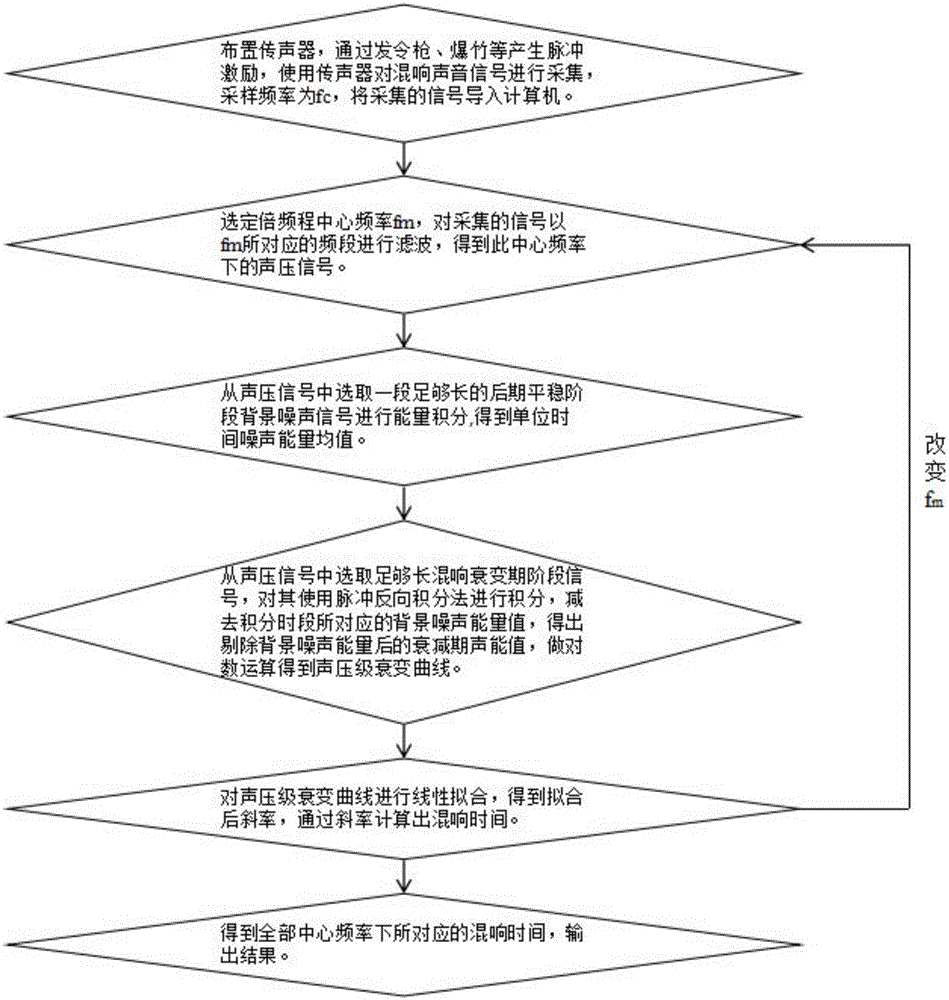

[0053] S01: Arrange three groups of microphones in the factory building, generate pulse excitation sources through starting guns or firecrackers, use the microphones to collect reverberation sound signals, and the sampling frequency is f c =51200, the number of sampling points N=2048000, import the collected signal into the computer for analysis;

[0054] S02: Select the octave center frequency f according to GBT 50076-2013 m =125×2 m Hz, where 0≤m≤5, first select when m=0, f m =f 0 = 125Hz;

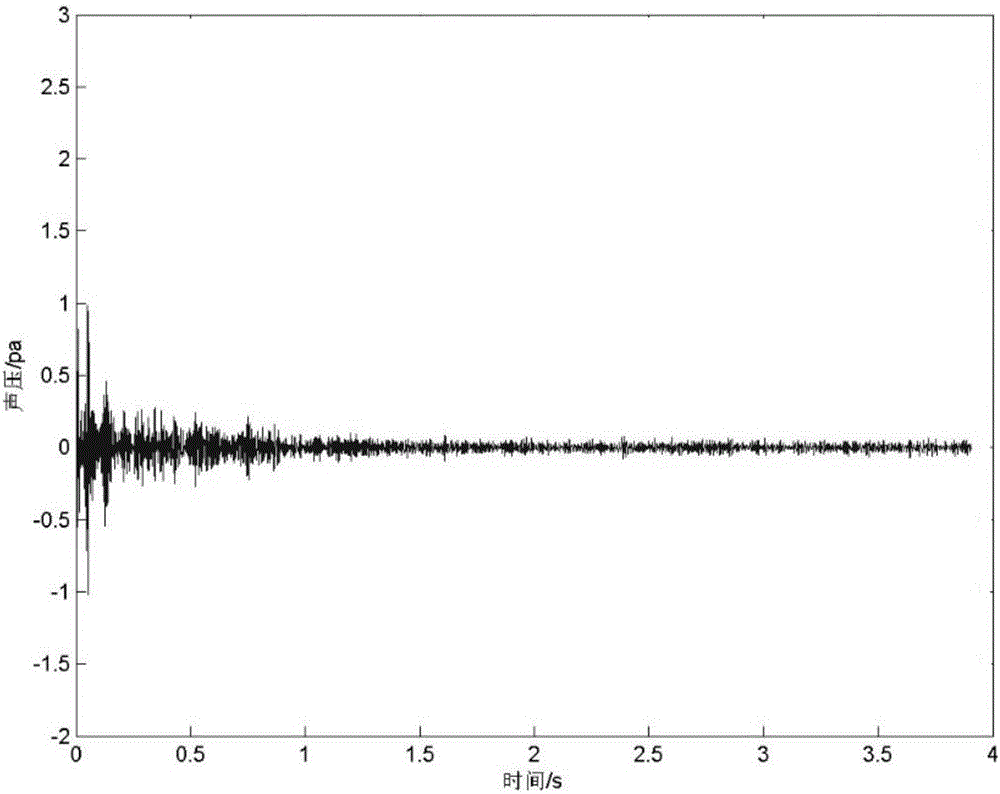

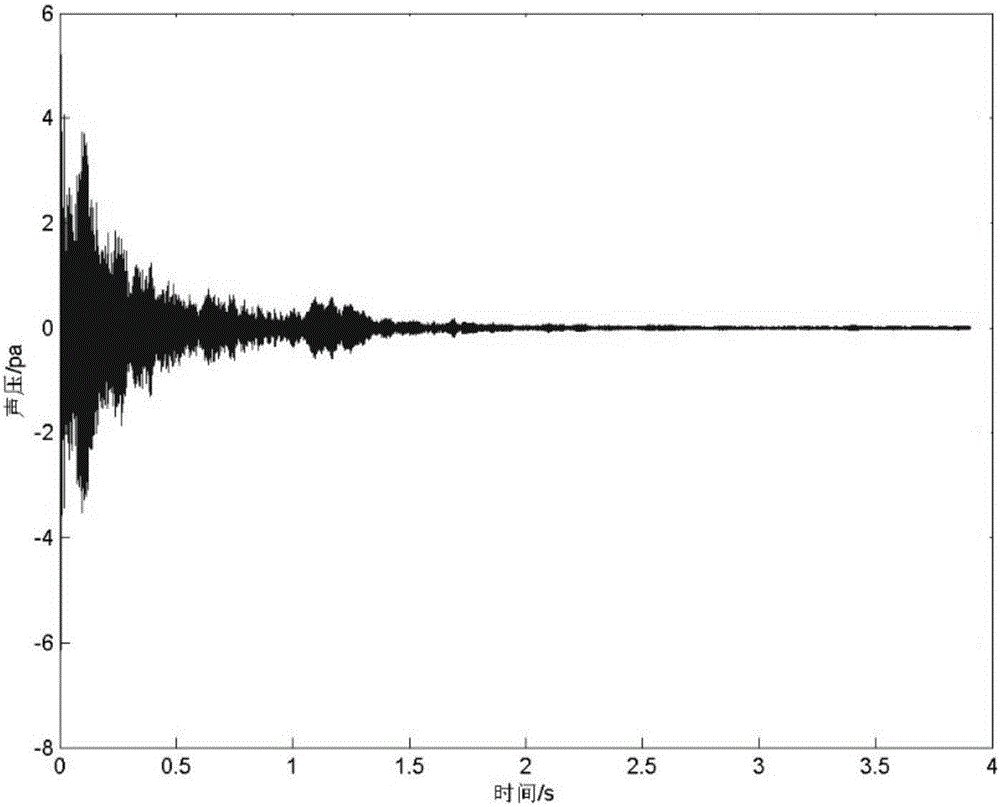

[0055] S03: For the signals collected by the first group of microphones, f 0The corresponding frequency band (90Hz~180Hz) is filtered to obtain the sound pressure signal p at this center frequency 0 (τ), such as figure 1 shown;

[0056] S04: From p 0 In (τ), select a sufficiently long background noise signal in the late stationary stage for energy integration, and obtain the average value of the noise energy per unit time

[0057]

[0058] In the formula: t 3 It is the tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com