Internet of Things-based landfill leakage monitoring system

A landfill and monitoring system technology, which is applied in the field of landfill leakage monitoring system based on the Internet of Things, can solve the problems of real-time remote control, low detection horizontal resolution, and complicated wiring settings, etc., to achieve the realization of arrangement Effects of monitoring, expanding the scope of monitoring, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

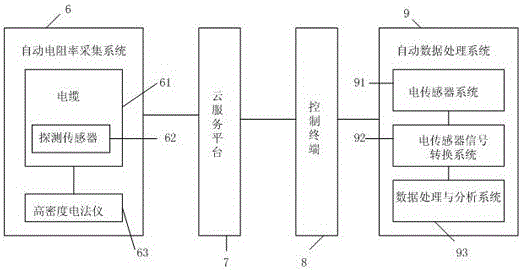

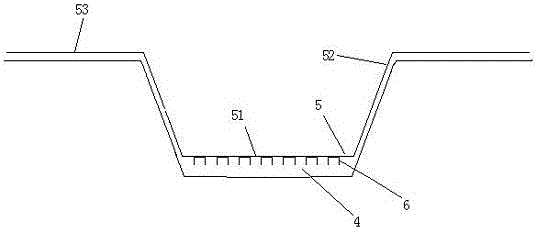

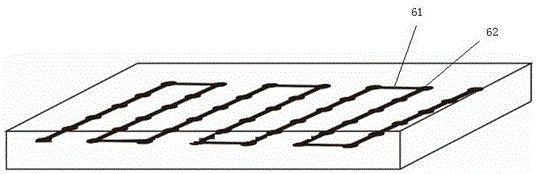

[0020] Please refer to Figure 1-Figure 5 , the landfill in this embodiment is successively landfill layer 1, gravel diversion layer 2, clay layer 3 on the film and clay layer 4 under the film from top to bottom, the bottom of the clay layer 3 on the film and the landfill The two sides of the buried layer 1, the gravel diversion layer 2 and the clay layer 3 on the membrane are wrapped with an anti-seepage membrane 5, and the lower side of the anti-seepage membrane 5 is provided with an automatic resistivity acquisition system 6. The automatic resistivity acquisition system 6 includes cables 61, The detection sensor 62 and the high-density electrical instrument 63, the cables 61 are arranged in a bow shape on the lower side of the anti-seepage film 5, the detection sensor 62 is arranged on the cable 61, and the high-density electrical instrument 63 is fixed at the end of the cable 61, The automatic resistivity acquisition system 6 is connected to the cloud service platform 7, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com