A semi-cemented artificial core model and its sand filling device and method

A technology of core model and cementation, which is applied in the field of semi-cemented artificial core model and its sand filling device, can solve the problems of reducing production cost, changing the core structure, and being easily glued to death, so as to reduce production cost, make simple production, and simulate data small error effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] A semi-cemented man-made sand-filled pipe core model according to the present invention is composed of a transparent organic glass pipe, a quartz sand filling area in the middle and a sand grain cementation area at both ends. In one embodiment of the present invention, the outer diameter of the plexiglass tube is 25 mm, the inner diameter is 21 mm, the wall thickness of the tube is 2 mm, and the length is 60 mm.

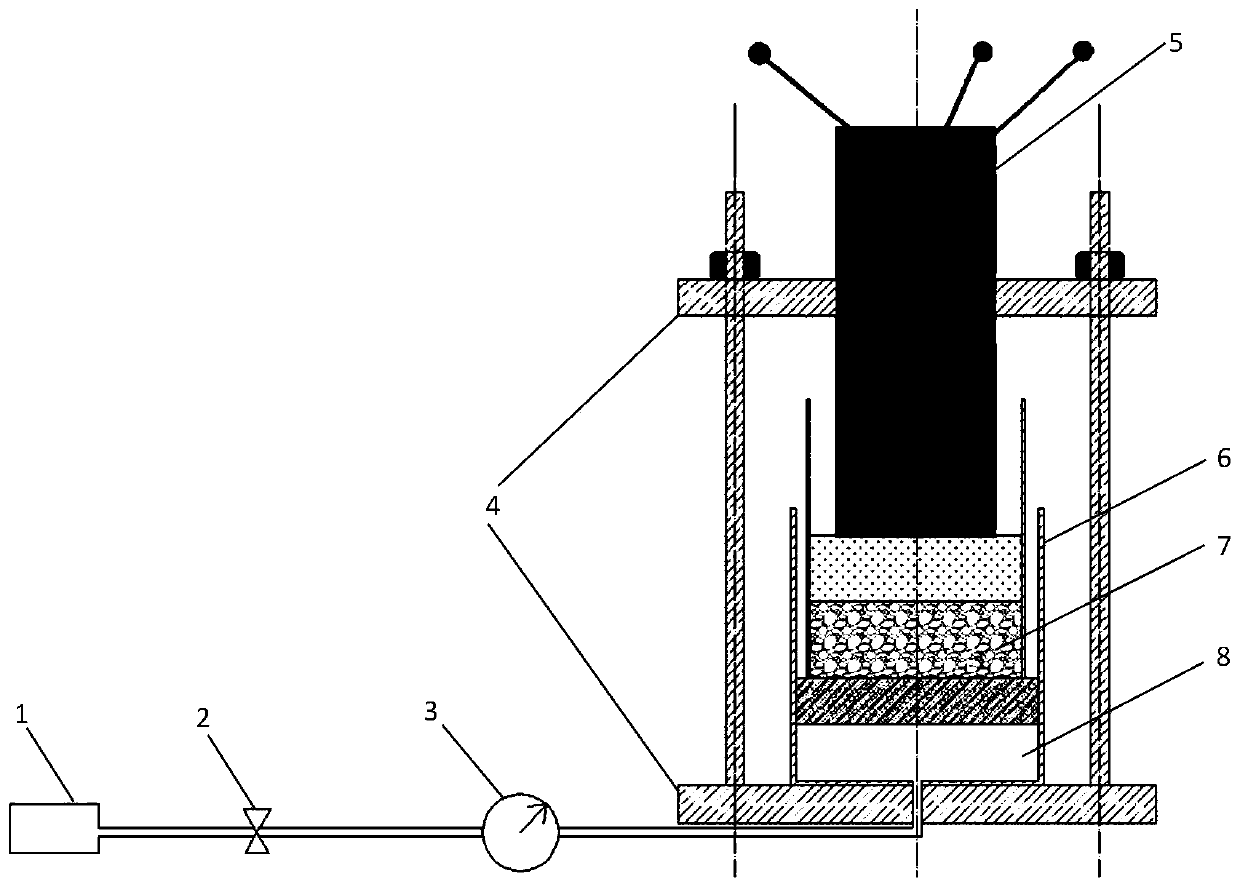

[0037] A kind of sand filling device of this artificial core model according to the present invention, such as figure 1 As shown, the device includes a manual hydraulic booster pump 1, a pressure relief valve 2, a pressure gauge 3, a fixed bracket 4, a solid threaded iron rod 5, and an intermediate container 6 with a stopper open at one end. Core tube 7 as figure 1 Placed, the pressurized working fluid of the intermediate container is water 8, the manual hydraulic booster pump 1, the pressure relief valve 2, the pressure gauge 3 and the plugged intermediate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com