A device and method for testing the corrosion fatigue performance of non-metallic coatings

A non-metallic coating, corrosion fatigue technology, used in measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve the problem of lack of real-time leak detection devices and methods for coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A detailed description will be made in conjunction with the drawings and specific embodiments of the present invention.

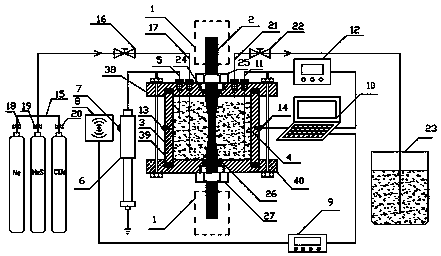

[0045] like Figure 1~4 As shown, a test device for corrosion fatigue performance of non-metallic coatings is characterized in that the device includes a test unit, a monitoring unit, a camera observation unit, a heating unit, and an intake and exhaust unit;

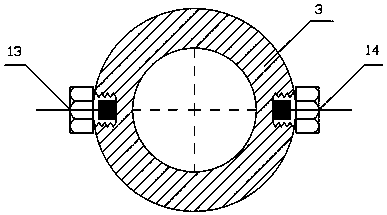

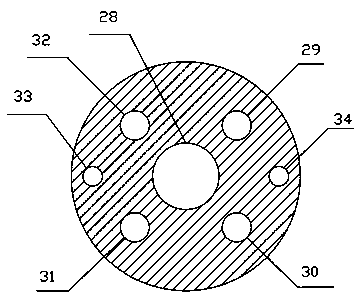

[0046] Described test unit is made of tension-compression fatigue testing machine (1), sample (2), environment box (3) and corrosive liquid (4); Described environment box (3) is made up of upper end cover (38), environment Composed of a cylinder (39) and a lower end cover (40), it is in a cylindrical sealed structure and is made of transparent organic glass. The working pressure in the environmental chamber (3) is 0.1MPa, and the working temperature range is 0-80°C; The sample (2) passes through the upper end cover sample jack (28) and the lower end cover sample jack (35) of the environmental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com