Diamond press anvil crack online detection method based on acoustic emission signal

An acoustic emission signal and detection method technology, which is applied in the direction of material analysis, computer parts, instruments, etc., using acoustic emission technology, can solve the problems of no establishment of intelligent identification, no self-learning, limited scope of application, etc., to achieve the benefit of online Application, fast calculation speed, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Embodiments of the present invention are described in detail below, and the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

[0090] A method for on-line detection of cracks in the top hammer of a diamond press based on acoustic emission signals, the process of which is as follows figure 1 As shown, the BSA-SVM intelligent detection method and the K-SPWVD time-frequency signal analysis method are used comprehensively to detect anvil cracks. The specific steps are as follows:

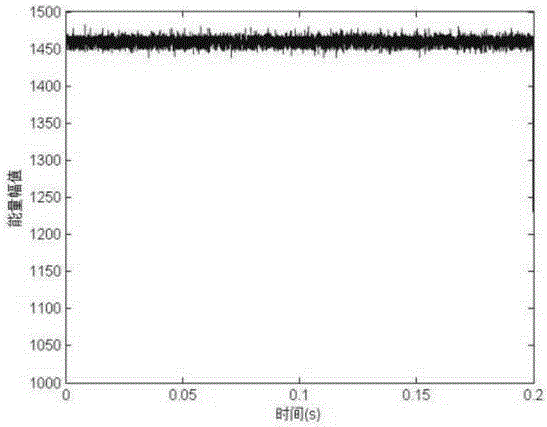

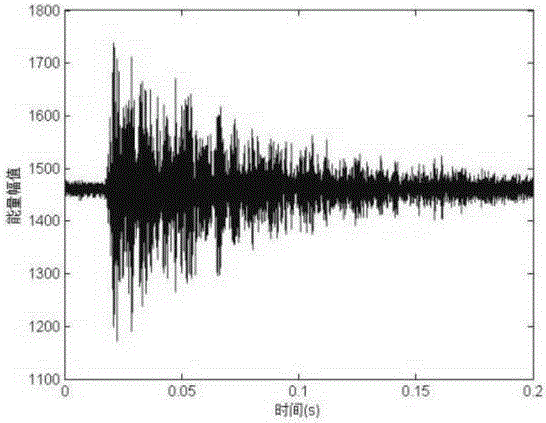

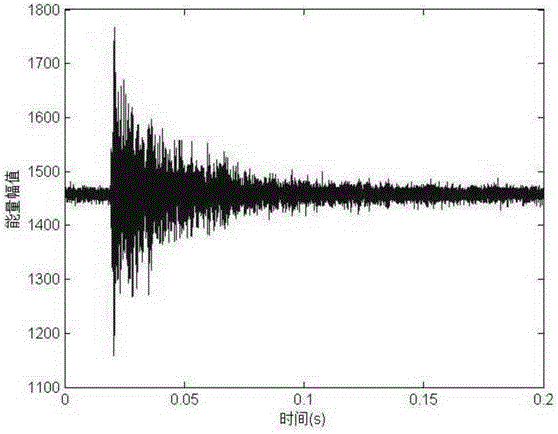

[0091] Step 1: Install an acoustic emission sensor on an anvil known to have cracks, first collect acoustic emission signals from an anvil known to have cracks, preprocess the signal collected by the sensor through a circuit, and convert the preprocessed The signal is input into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com