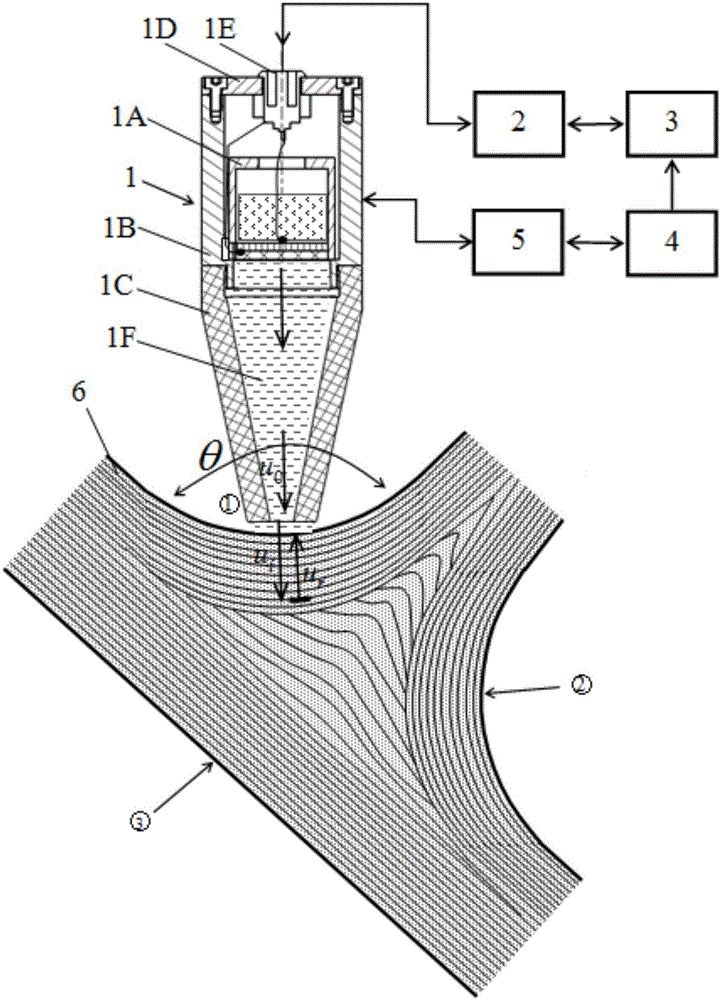

Liquid self-coupling ultrasonic transducer for composite material T-shaped connection area and detection method

An ultrasonic transducer and composite material technology, applied in the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the difficulties of implementation, misjudgment of defects, difficult detection, etc. problem, to achieve the effect of improving defect detection ability, improving reliability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

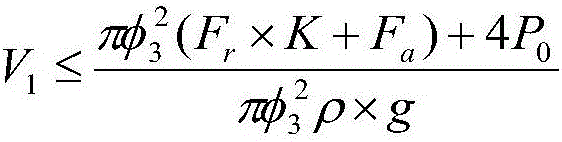

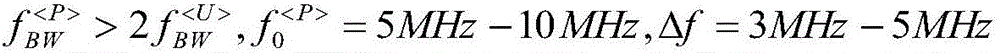

[0116] Using the patent of the present invention, choose UPowr-1, MUT1, FCC-B-1, FCC-D-1 manual ultrasonic testing equipment and CUS-6000, CUS-21J automatic scanning testing equipment produced by AVIC Composite Materials Co., Ltd. A series of practical detection applications have been carried out on the T-shaped connection area in a variety of composite material structures. Among them, the frequency of the transducer is 5MHz and 10MHz, and the T-shaped rib scanning method in the patent of the present invention is adopted, and manual and automatic scanning methods are adopted. , to carry out a series of scanning inspections on the T-shaped connection areas of different composite material structures. The size of the composite material structures with T-shaped ribs to be tested ranges from 100×100mm to 1500×5000mm. The actual test results of the series show that it is possible to detect Defects in the skin area, filling area, and skin-filling area interface in the T-shaped connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com