Testing device and method for absorption coefficient of concrete type material

A testing device and concrete technology, which is applied in the direction of measuring devices, analysis materials, material inspection products, etc., can solve the problems of difficult to obtain test data accurately, large measurement errors, time-consuming and labor-intensive, etc., and achieve simple assembly, simple structure, The effect of accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

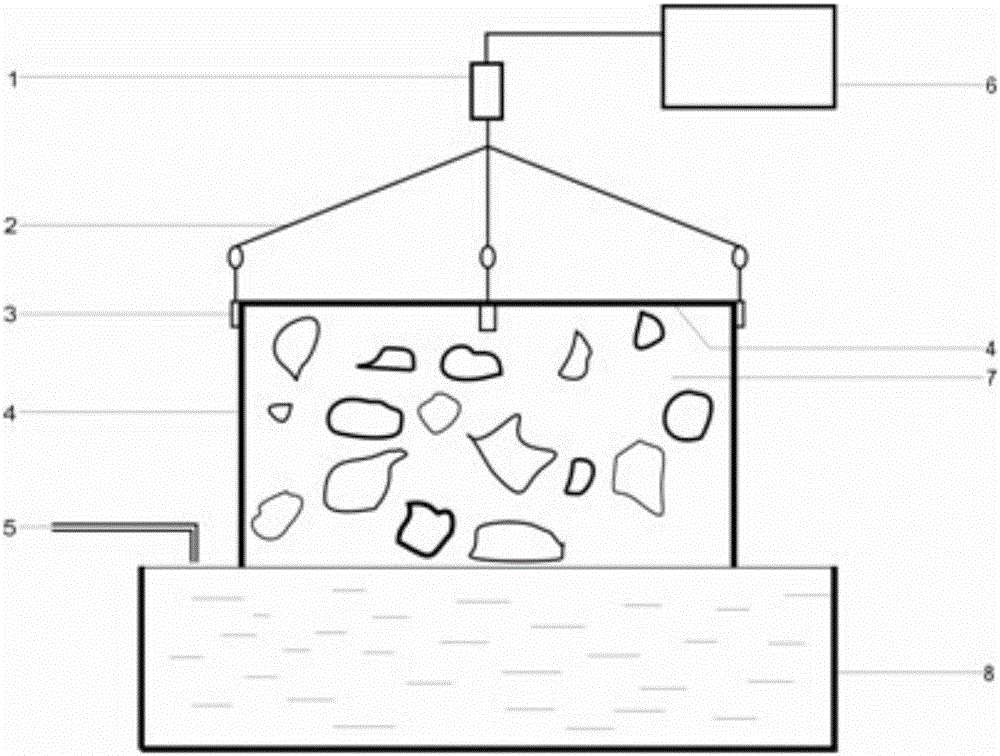

[0028] Specific Embodiment 1: This embodiment provides a test device for the water absorption coefficient of concrete materials, such as figure 1 As shown, the test device is composed of a digital display dynamometer 1, a rope 2, a hook 3, a water inlet pipe 5, a computer 6, a test piece 7, and a water container 8, wherein:

[0029] The upper surface and sides of the test piece 7 are covered with epoxy resin 4;

[0030] The upper part of the rope 2 is connected with the digital display dynamometer 1, the digital display dynamometer 1 is connected with the computer 6, the lower part of the rope 2 is connected with the upper part of the test piece 7 through the hook 3, and the test piece 7 is connected with the hook 3 and the rope 2. When hoisting, the lower surface of the test piece 7 is at the same height as the upper edge of the water container 8 or slightly lower than the upper edge of the water container 8;

[0031] The water container 8 is provided with a water inlet pipe...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment provides a method for testing the water absorption coefficient of concrete materials using the test device described in Embodiment 1. The specific implementation steps are as follows:

[0034] 1. Perform preprocessing on specimen 7 according to Article 8 of ASTM C1585-13;

[0035] Two, the upper surface and the side of the test piece 7 are covered with epoxy resin 4;

[0036] 3. Use the hook 3 and the rope 2 to lift the test piece 7, the upper part of the rope 2 is connected with the digital display dynamometer 1, the digital display dynamometer is connected with the computer 6, and the lower surface of the test piece 7 is at the upper edge of the water container 8. The same height or slightly lower than the upper edge of the water container 8;

[0037] 4. Turn on the digital display dynamometer 1 to start the test;

[0038] 5. Open the water inlet pipe and slowly inject water into the water container 8;

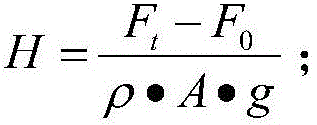

[0039] 6. The water absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com