Battery voltage acquisition and calibration circuit

A battery voltage and calibration circuit technology, which is applied in the direction of measuring current/voltage, measuring electrical variables, and using digital measurement technology to measure, can solve the problems of high price and high product cost, and achieve low cost, simple structure, and good performance. The effect of economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

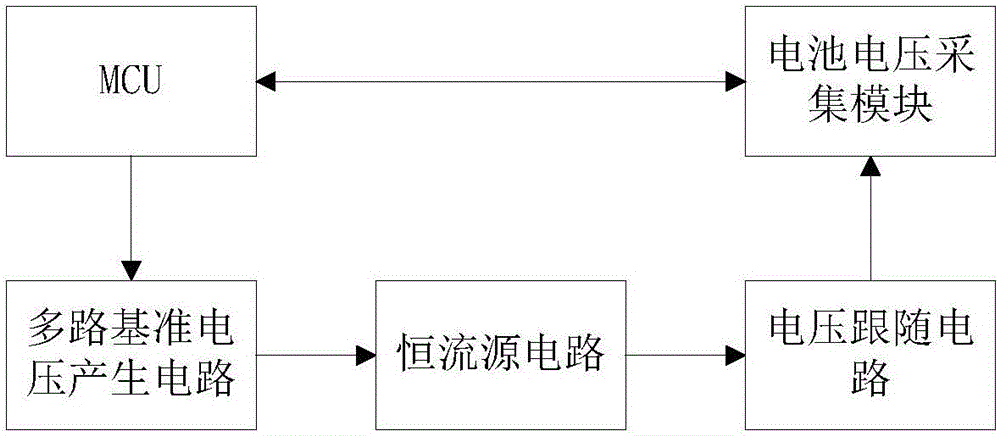

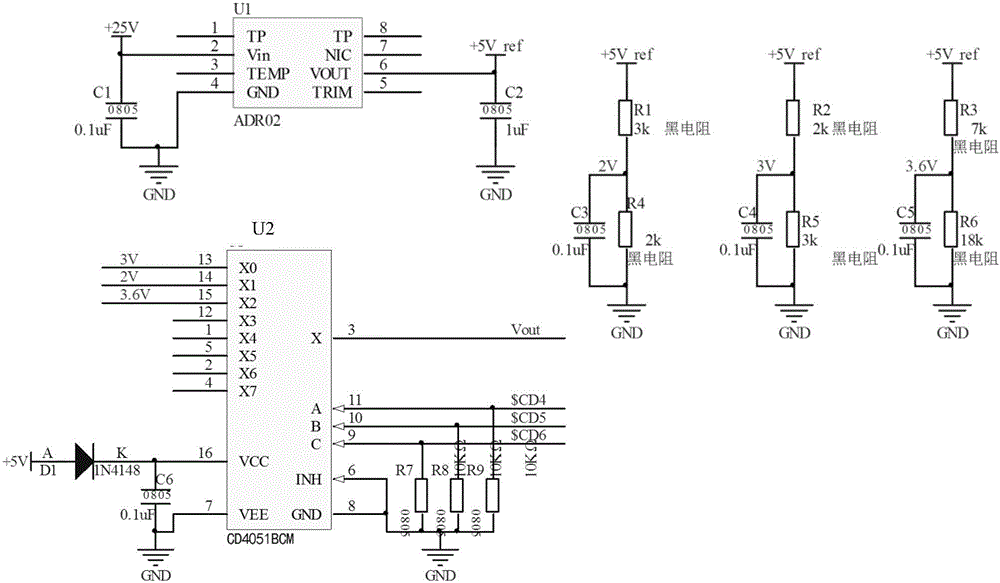

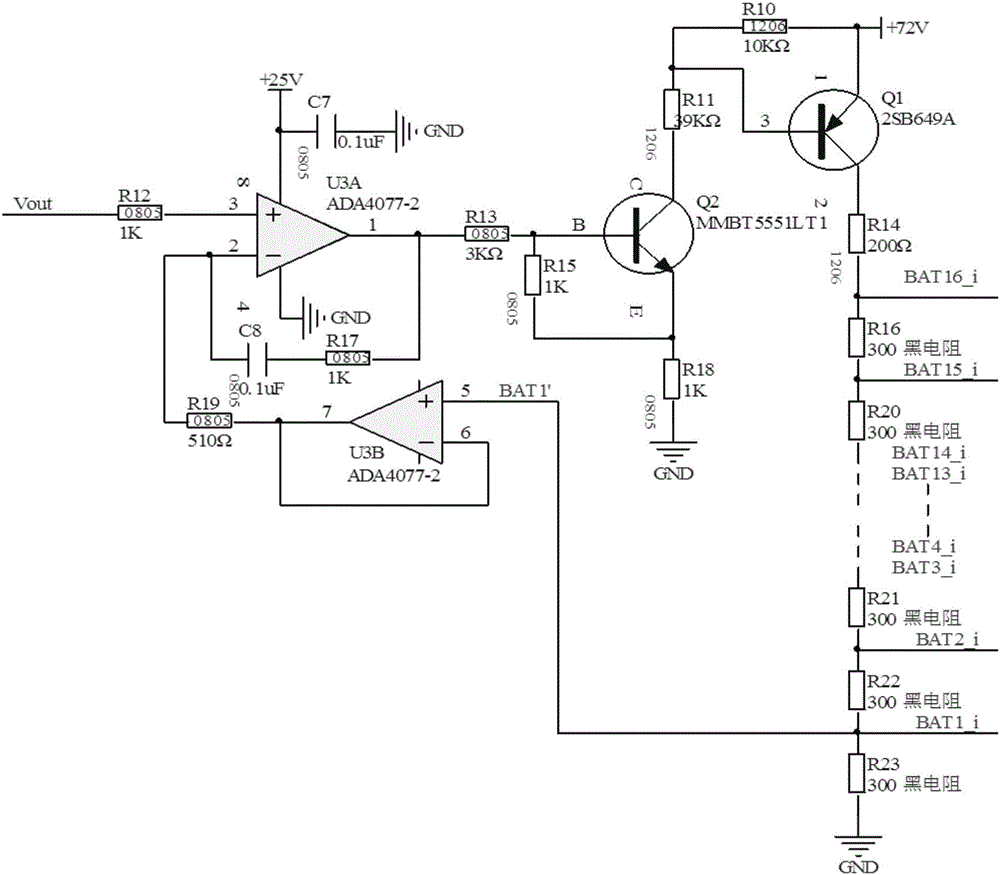

[0019] like figure 1 As shown, a battery voltage acquisition and calibration circuit includes a battery voltage acquisition module, and also includes an MCU, a multi-channel reference voltage generation circuit, a constant current source circuit, and a voltage follower circuit. The output terminal of the MCU is connected to the multi-channel reference voltage. The input end of the generation circuit is connected, the multi-channel reference voltage generation circuit can generate multiple high-precision reference voltages, and the MCU can control the multi-channel high-precision reference voltage generation circuit to output a variety of high-precision reference voltages; the multi-channel reference voltage The output end of the voltage acquisition circuit is sequentially connected to the battery voltage a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com