Device for online monitoring of dielectric strength of insulating oil of high-voltage oil-filling power equipment

An oil-filled equipment and dielectric strength technology, which is applied in the direction of testing dielectric strength, measuring devices, and measuring electricity, can solve problems such as insufficient analysis accuracy, multiple types of gas detection, and complex comprehensive diagnostic methods, etc., to achieve convenient and repeated use , to avoid the effect of false positives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

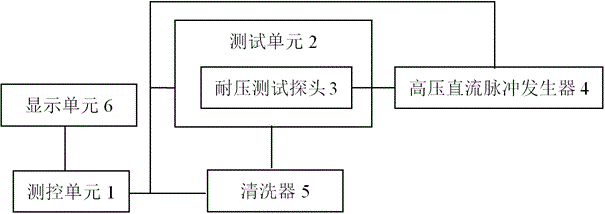

[0041] Such as figure 1 As shown, an on-line monitoring device for the dielectric strength of insulating oil of electric high-voltage oil-filled equipment, which includes: a high-voltage direct current pulse generator 4, which is used to generate a unipolar voltage pulse signal; a test unit 2, which is used to obtain The insulating oil to be tested is composed of a liquid pressure reducing valve and a sealing structure in this embodiment; the withstand voltage test probe 3 is arranged in the test unit 2 as a detection device and is electrically connected to the high-voltage direct current pulse generator 4, The electrode gap of the probe part is adjustable, so that the voltage between the insulating oil insulation gaps to be tested is adjustable; the measurement and control unit 2 is connected to the high-voltage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com