Fiber bending mode eliminating device and method

A bending and mold elimination technology, applied in the field of nuclear physics detection, can solve the problems of damage stability guarantee, manufacturing difficulty, unfavorable transmission power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

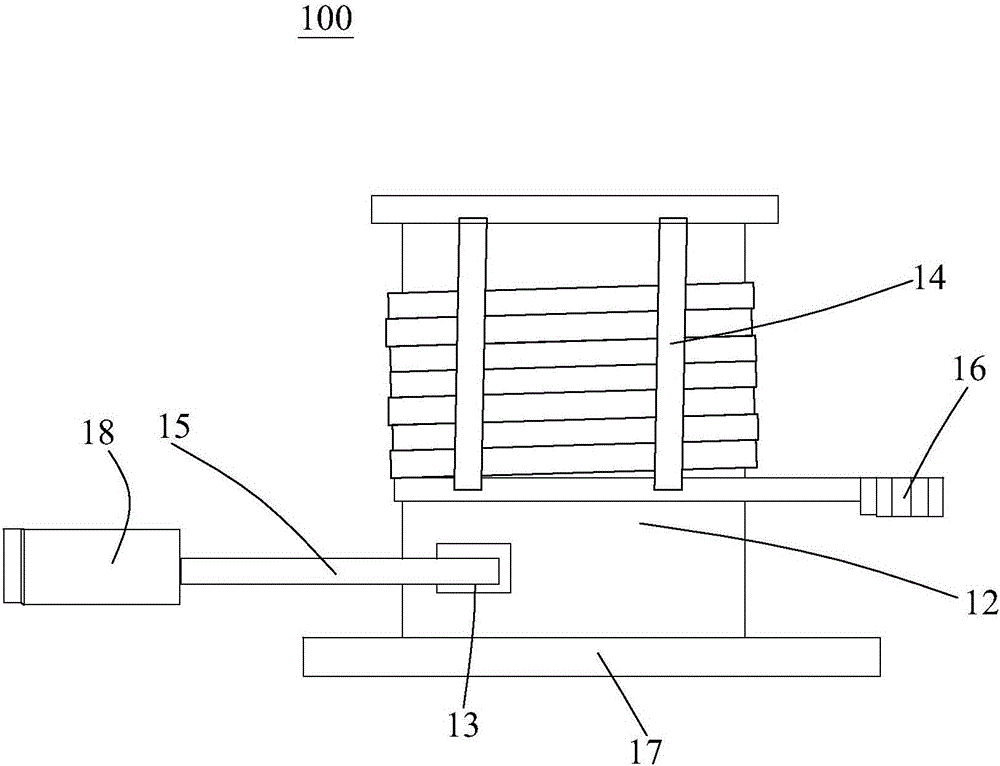

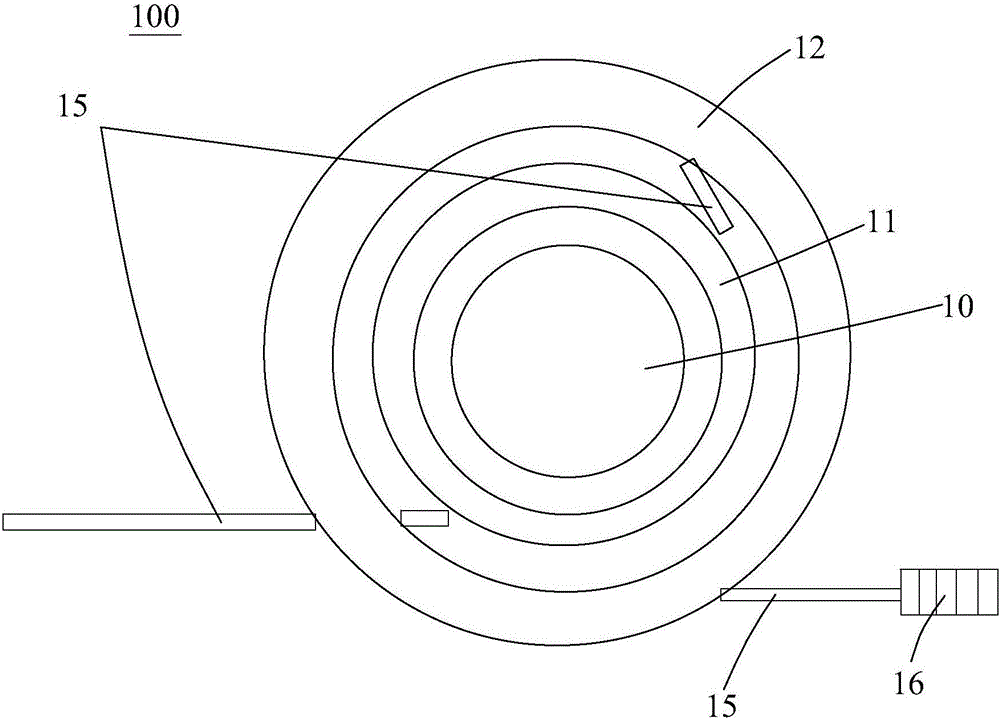

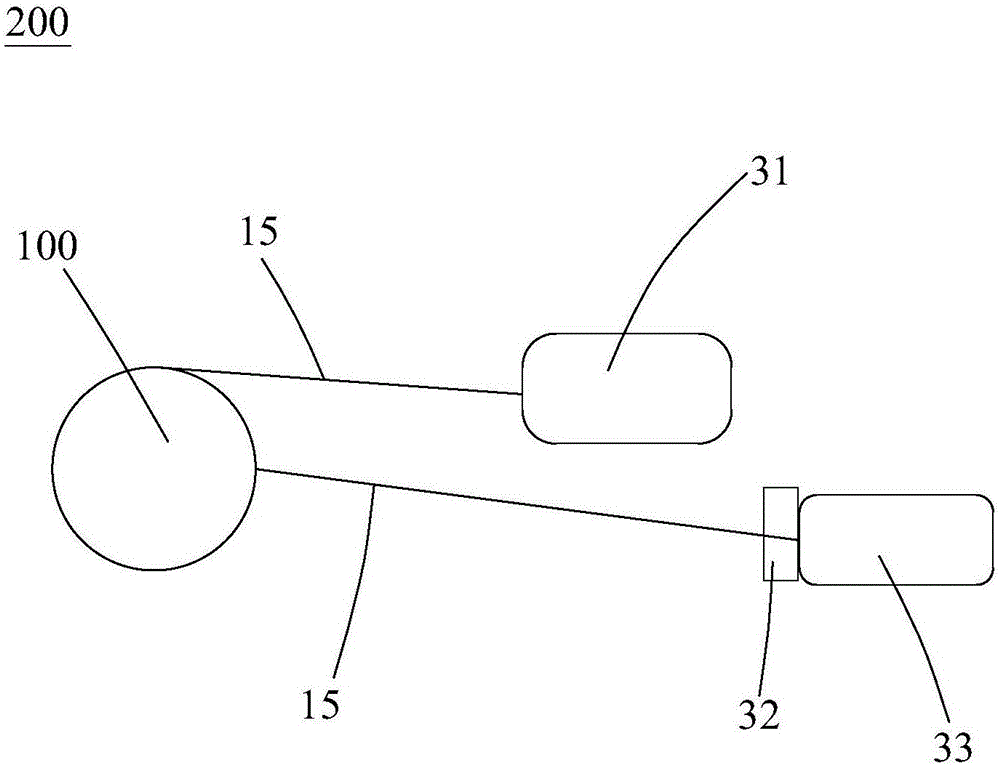

[0019] refer to figure 1 and figure 2 , the present invention discloses an optical fiber bending mode elimination device 100, comprising an annular inner coiling mold 11, an outer coiling mold 12 and a multimode optical fiber 15 surrounding the inner coiling mold 11 at a certain distance, the outer coiling mold 12 is provided with a through hole 13, a part of the multimode optical fiber 15 is wound on the inner coiling mold 11, and the other part passes through the through hole 13 and is wound on the outer coiling mold 12, so that the multimode optical fiber 15 forms a small-radius coiled portion wound on the inner coiled mold 11 and a large-radius coiled portion wound on the outer coiled mold 12 . Among them, since the core diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com