Electric-kettle water level detection method

A technology of water level detection and electric kettle, which is applied in the direction of liquid level indicator, instrument and computer control of physical variable measurement, which can solve the problems of misjudgment, increase of water resistance, large water resistance, etc. short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

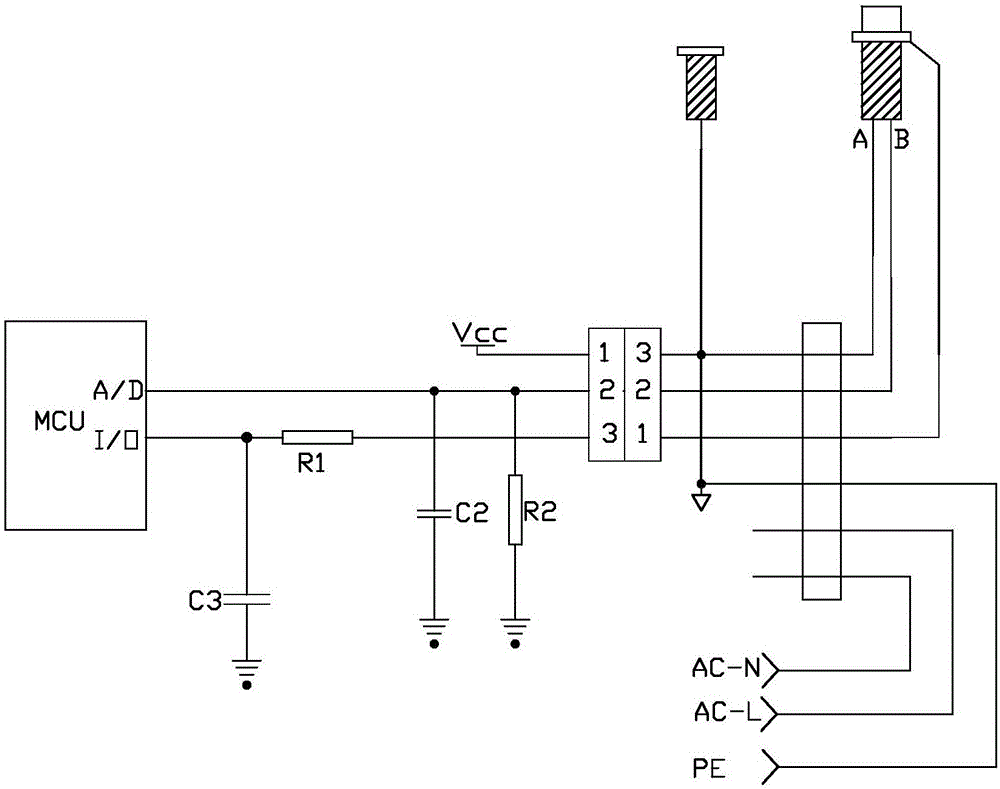

[0037] refer to figure 1 Shown, propose embodiment 1 of the present invention:

[0038] The electric kettle of the present invention includes a host and a kettle body, the host is provided with a coupler and a single-chip microcomputer, and the single-chip microcomputer includes an I / O terminal and an A / D terminal; the coupler is connected with the single-chip microcomputer, and a chamber is provided in the kettle body. A water level detection probe wrapped with an insulating material is provided at the bottom of the chamber. The pot body and the water level detection probe are respectively connected to the single-chip microcomputer through a coupler. The water level detection probe includes an A terminal and a B terminal. The upper end of the water level detection probe is exposed in the chamber and the vertical distance from the upper end of the water level detection probe to the bottom of the chamber is 5-45mm. The insulating material includes but not limited to ceramics an...

Embodiment 2

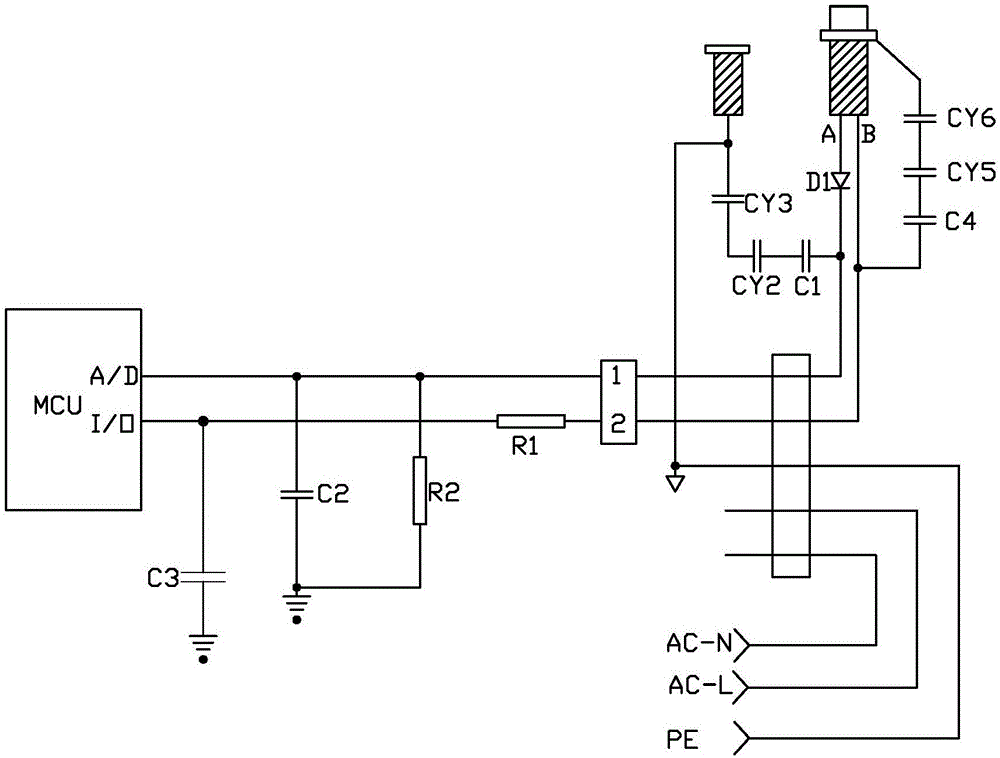

[0050] refer to figure 2 Shown, propose embodiment 2 of the present invention:

[0051] A terminal of the water level detection probe is connected in parallel with the capacitor C2 and resistor R2 through a diode D1 and a coupler, and then connected to the A / D terminal of the single-chip microcomputer. I / O terminal connection,;

[0052] It also includes the first group of capacitors. The first group of capacitors is composed of capacitor C1, capacitor CY2 and capacitor CY3 in series, of which capacitor CY2 and capacitor CY3 are safety capacitors; after C1, capacitor CY2 and capacitor CY3 are connected in series, one end is connected to the water level detection probe A One end is connected, and the other end is connected with the pot body;

[0053] It also includes a second group of capacitors. The second group of capacitors is composed of capacitor C4, capacitor CY5 and capacitor CY6 in series, wherein capacitor CY5 and capacitor CY6 are safety capacitors; after capacitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com