Well head and well bottom pressure conversion method for shale gas horizontal well under two-phase flow conditions

A bottomhole pressure and horizontal well technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of wellbore flow pattern changes, large calculation errors, complex pressure and temperature distribution, etc., and achieve accurate and reliable analysis results. Apply simple, thoughtful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

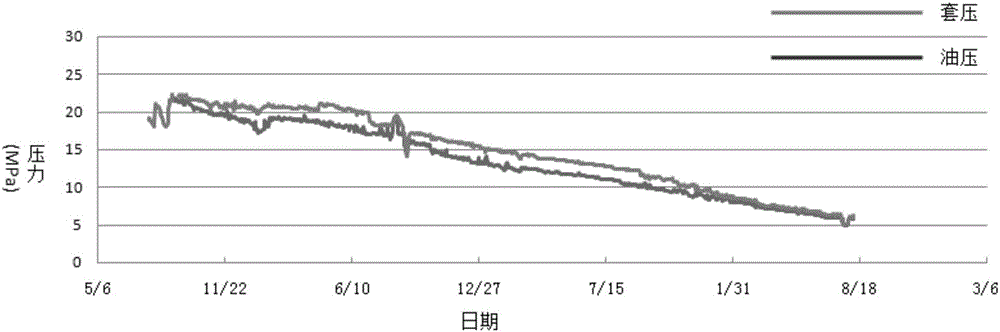

[0023] Step 1, production well production, pressure, temperature and other data recording, during the production of Jiaoye XHF well in Fuling shale gas field, recording wellhead production and pressure data (such as figure 1 ), use electronic pressure gauges to record downhole pressure and temperature data, and use production profile testing instruments to record data such as pressure, temperature, holdup rate and production during construction;

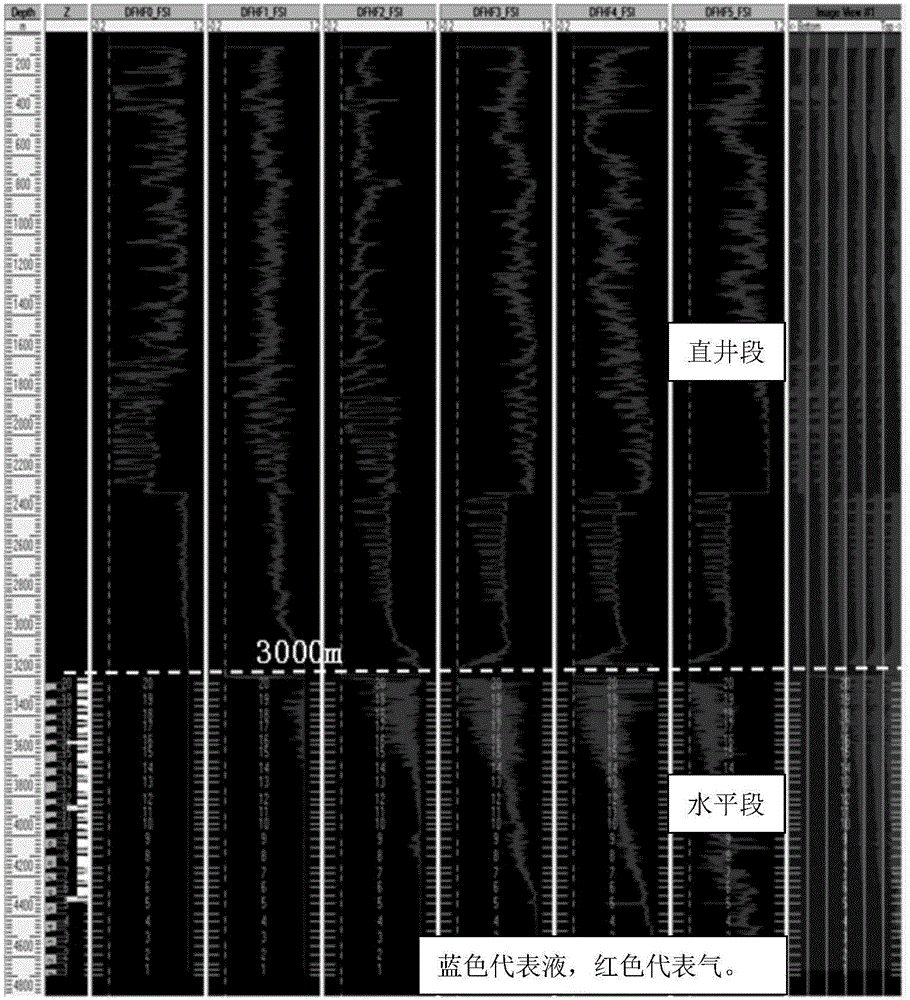

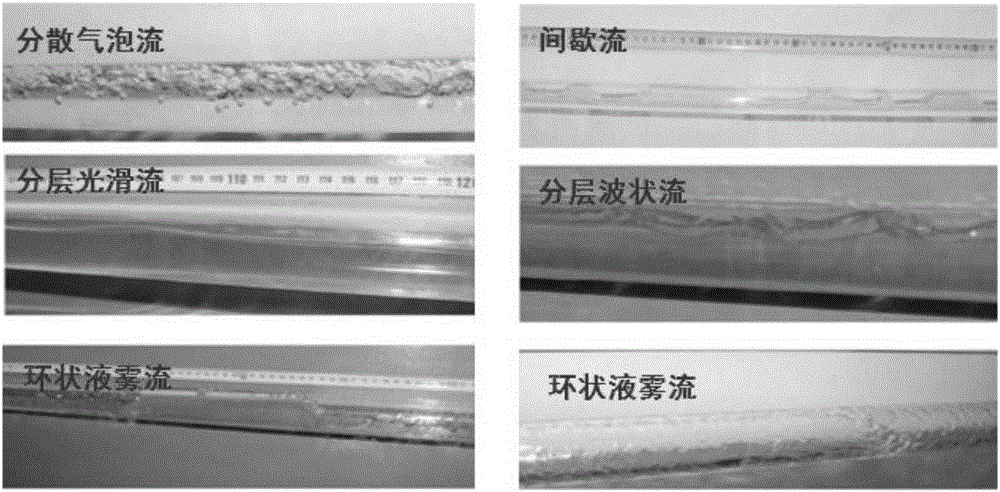

[0024] Step 2, the processing of the output profile test data. The gas-water distribution characteristics (such as figure 2 ), to determine the fluid flow state in the horizontal section and vertical section of the shale gas well (such as image 3 , Figure 4 );

[0025] Step 3, using the flow pressure data recorded in the profile test, the pressure gradient (unit: MPa / m) at each depth of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com