A method for building a full three-dimensional coupled model of a reactor u-tube steam generator

A steam generator and coupling model technology, applied in the direction of instrumentation, design optimization/simulation, computer-aided design, etc., to achieve model independence, ensure model calculation accuracy, and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention is described in further detail:

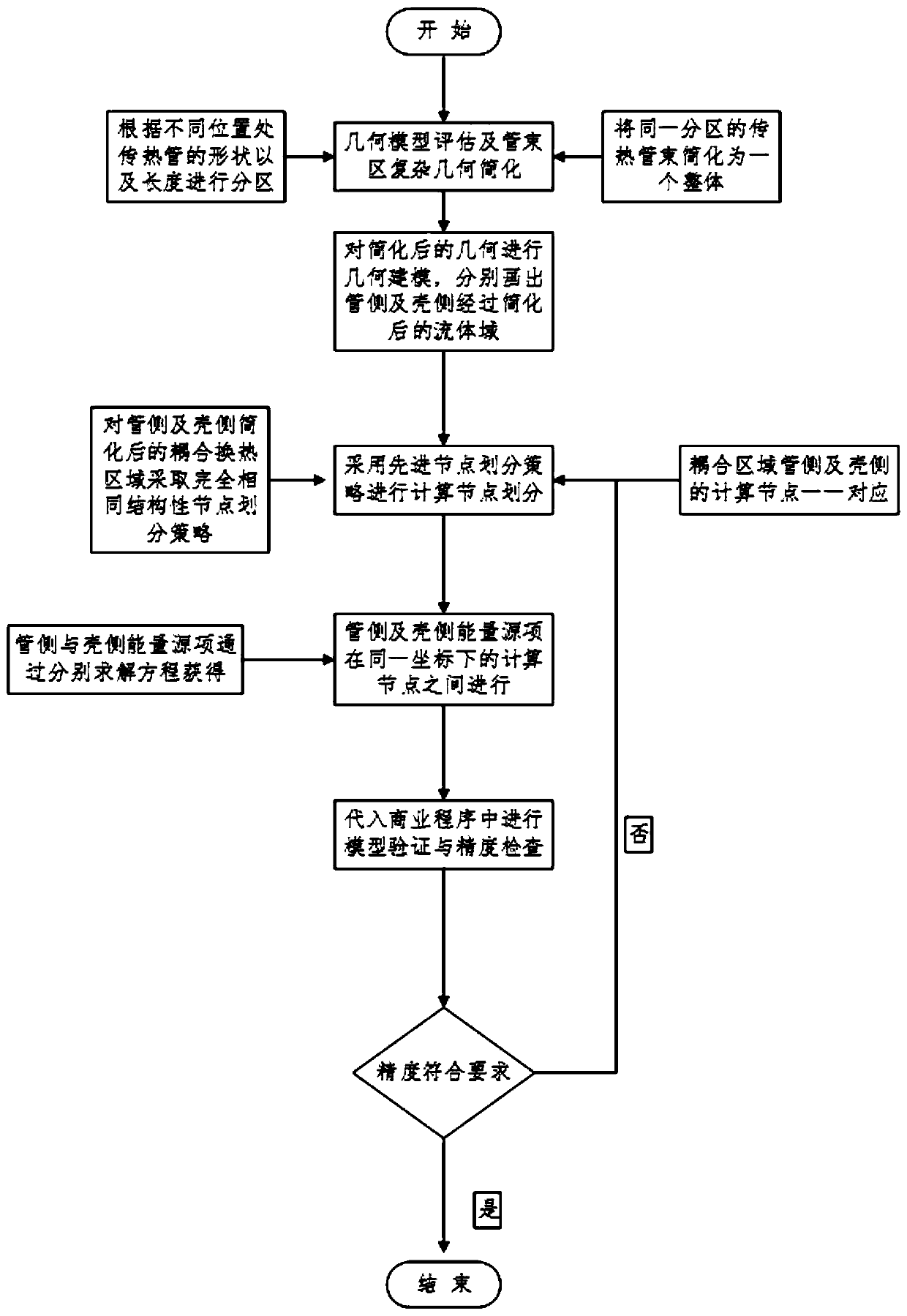

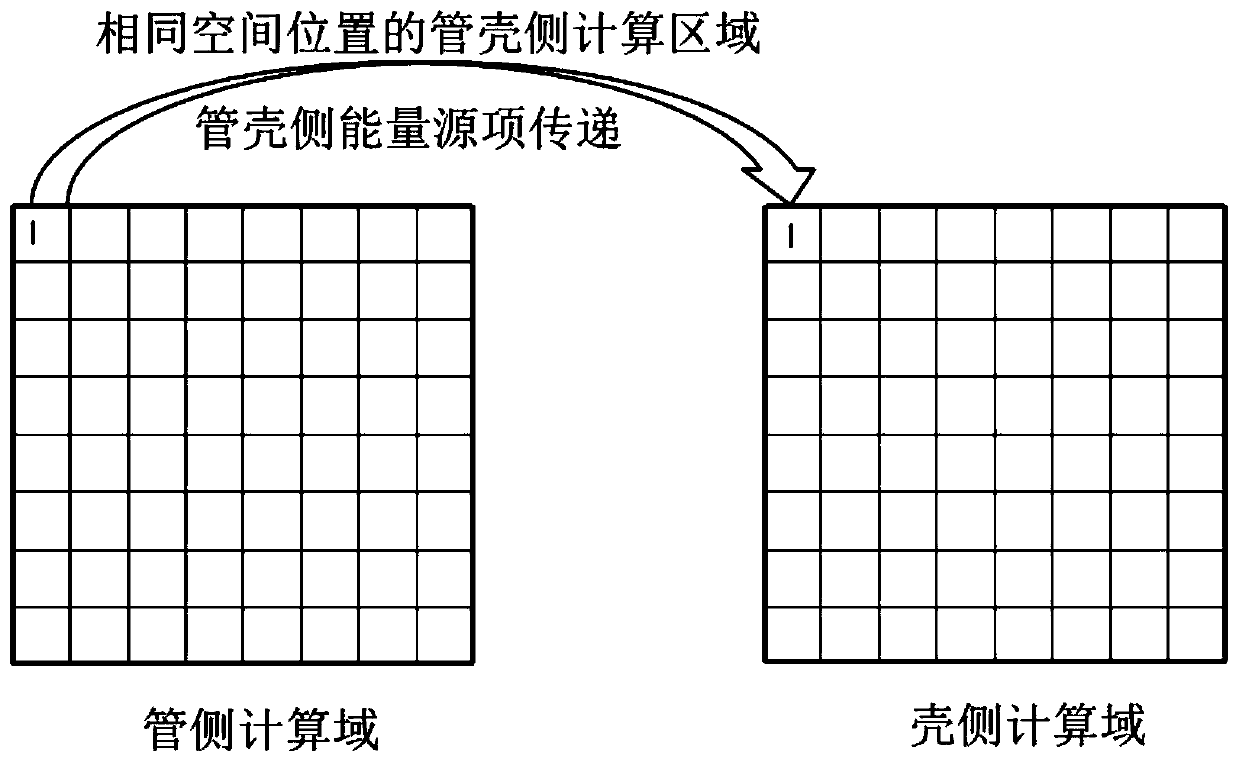

[0047] first according to figure 1 The flow chart of the establishment of the full three-dimensional thermal coupling model of the reactor U-shaped tubular steam generator provided, the model establishment method proposed in the present invention mainly includes the following parts: 1. simplification of the geometric model of the tube bundle area; 2. 1. Establishment of geometric model of porous medium on the secondary side; 3. Division of three-dimensional calculation nodes on the primary and secondary sides; 4. Calculation of energy source items on the primary and secondary sides; 5. Connection of primary and secondary side calculation nodes in the heat exchange coupling area Point processing and energy source item data transfer between primary and secondary nodes; 6. Coupling model inspection and calibration.

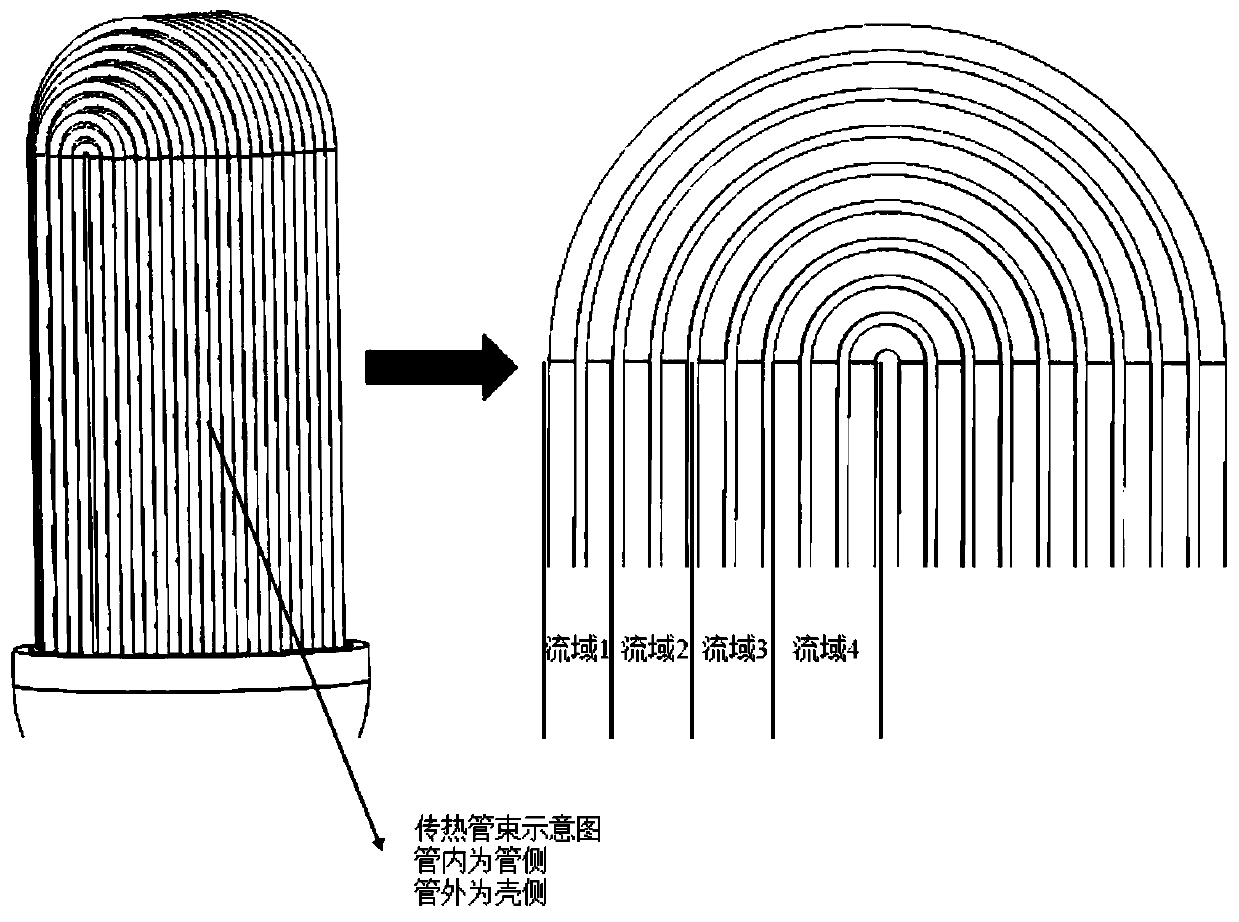

[0048] according to figure 2 The given geometric si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com