Oil damping hydraulic electromagnetic releasing mechanism and high-current circuit breaker with same

A technology of tripping mechanism and oil damper, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of unusable and direct winding, etc., and achieve the effect of easy processing and assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

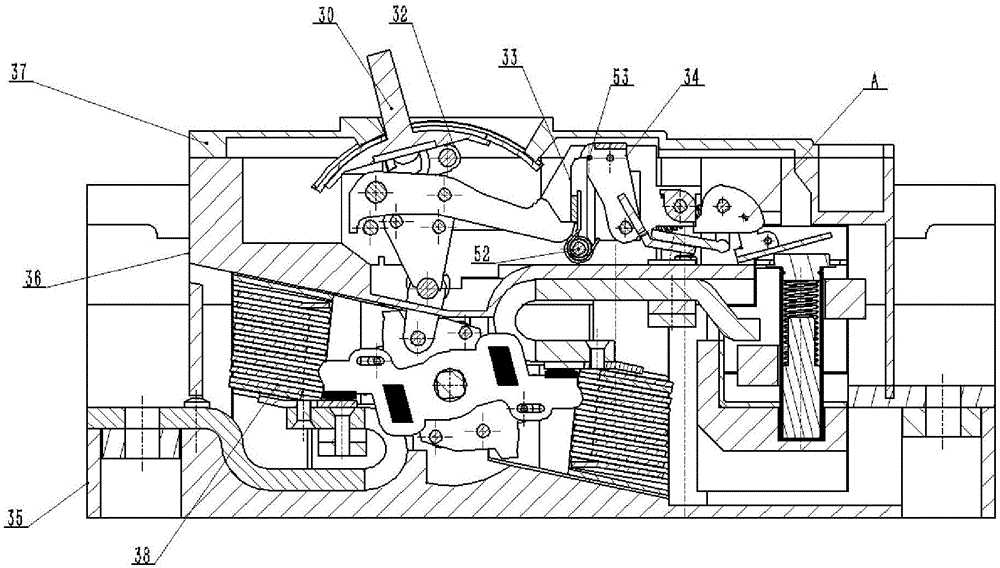

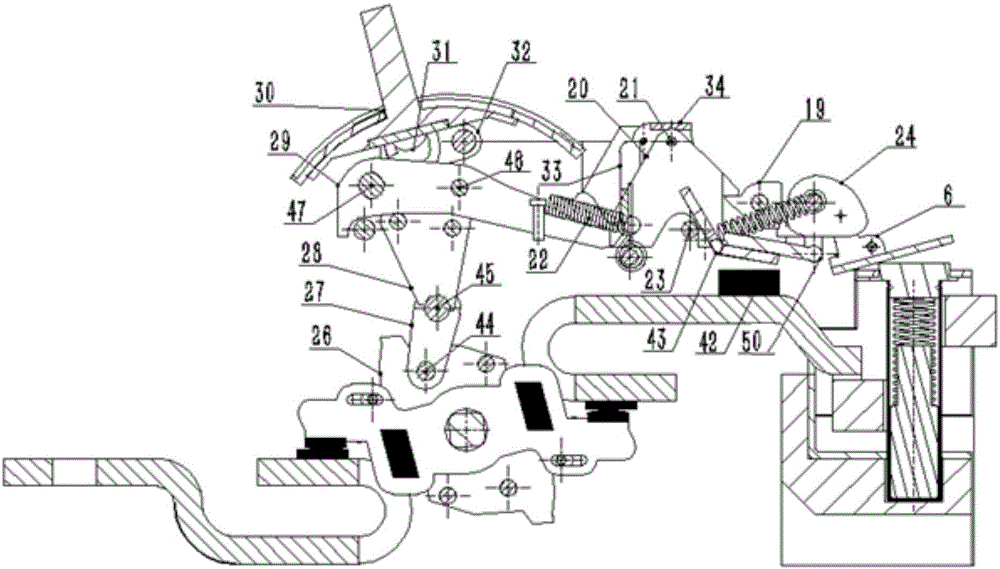

[0040] One embodiment of the present invention is a low-voltage molded case circuit breaker, which is a double-breakpoint circuit breaker with relatively large rated current, including a main circuit unit, an operating mechanism and an oil damping hydraulic electromagnetic tripping mechanism, and is also equipped with An electromagnetic tripping mechanism connected with the operating mechanism and a mechanical amplifying transmission mechanism arranged between the operating mechanism and the oil damping hydraulic electromagnetic tripping mechanism. In addition to the above-mentioned main components, the circuit breaker also includes components such as a base 35, a middle base 36, a cover 37, an arc extinguishing chamber 38 and corresponding fasteners.

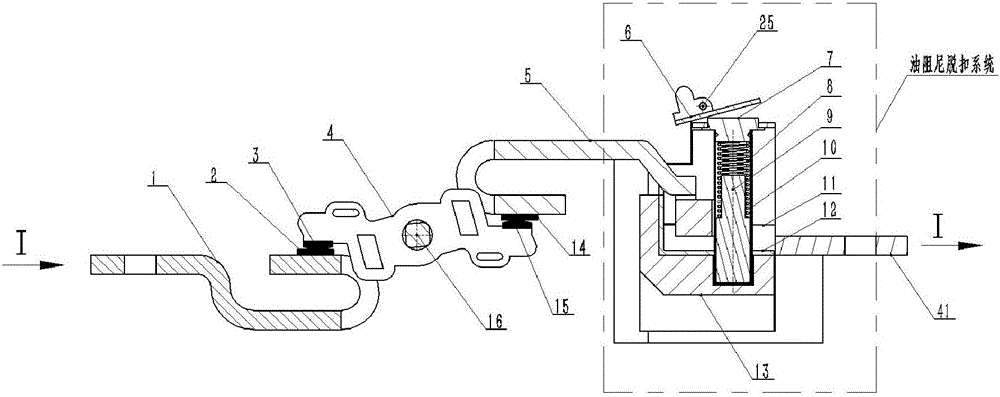

[0041] like image 3 As shown, the main circuit unit is mainly composed of the first static conductive bridge 1, the first static contact 2, the first movable contact 3, the movable conductive bridge 4, the second movable conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com