Electric connection assembly of lithium battery

A technology for electrical connection components and connectors, which is applied to battery pack parts, electrical components, circuits, etc., can solve problems such as low yield rate and easy cracks in products, and achieve high yield rate of production, ensure overcurrent capability, The effect of meeting the assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

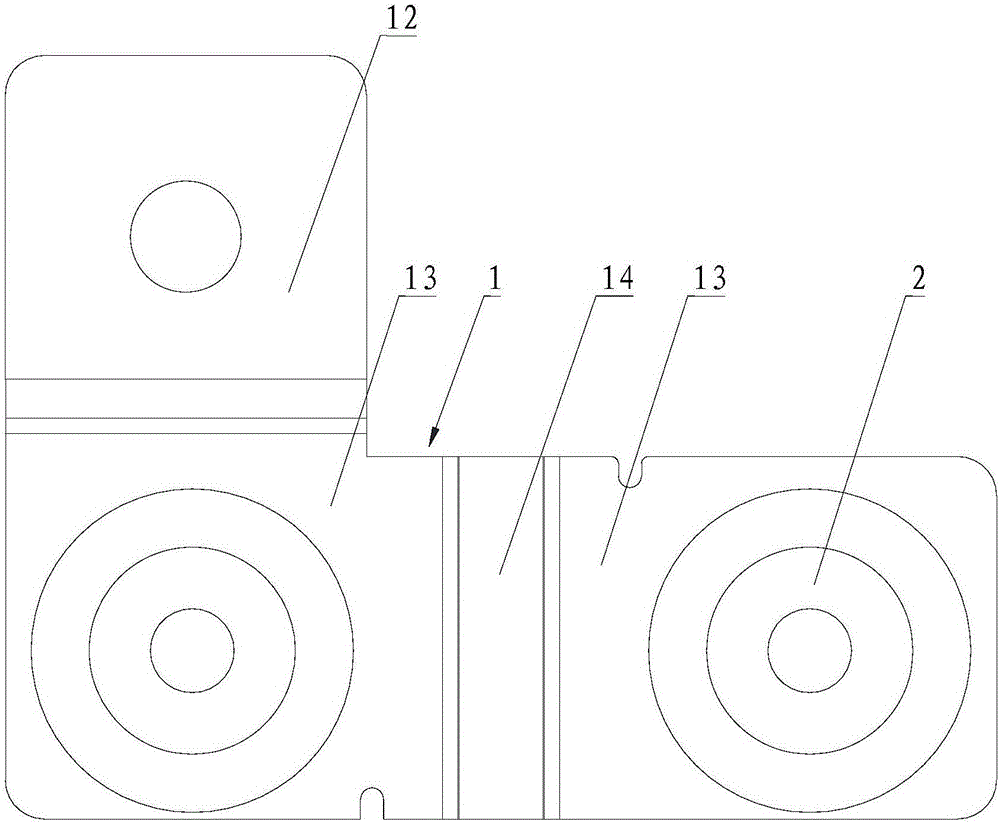

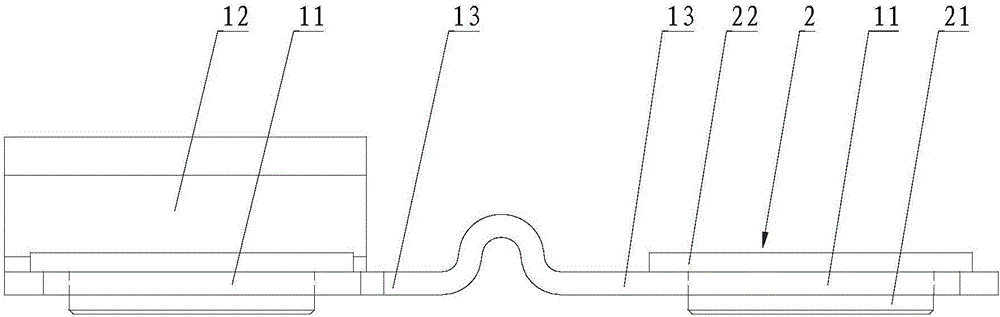

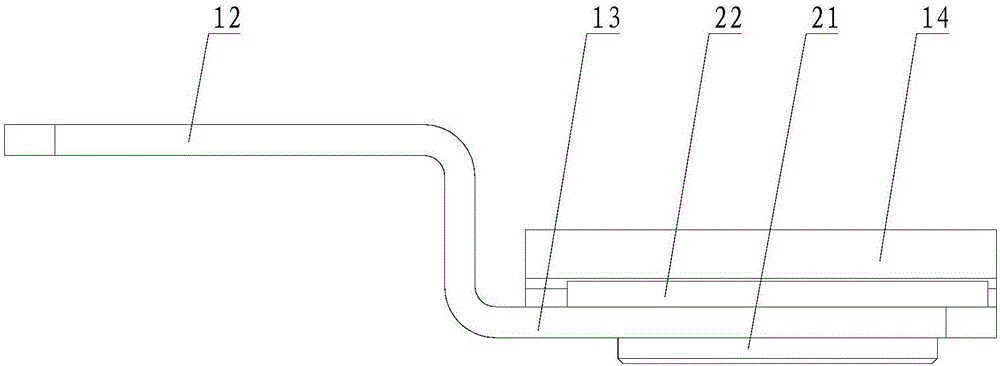

[0032] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is:

[0033] An electrical connection assembly for a lithium battery, comprising a first connector 1, a second connector 2 and a welding layer, the first connector 1 is made of copper, preferably T2 copper, and the second connector 2 is The material is aluminum alloy, such as 5005-H38 aluminum alloy, which has good electrical conductivity and high strength. The first connector 1 includes a first connecting piece 12 and a second connecting piece 13, the first connecting piece 12 is connected to the second connecting piece 13, and the connection between the first connecting piece 12 and the second connecting piece 13 is In a stepped structure, the second connecting piece 13 is provided with a connecting hole 11 . The surface of the first connecting piece 12 is provided with a plating layer, and the material of the plating layer is gold, silver, nickel or tin. The first connection piece 12 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com