A kind of synthetic method of lithium vanadate lithium ion battery cathode material

A material technology of lithium vanadate, lithium ion battery, applied in battery electrodes, vanadium compounds, secondary batteries, etc., to achieve the effects of easy interface correction, good rate performance and cycle performance, and precise control of atomic ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

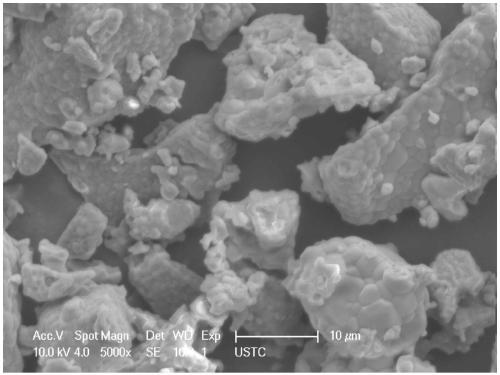

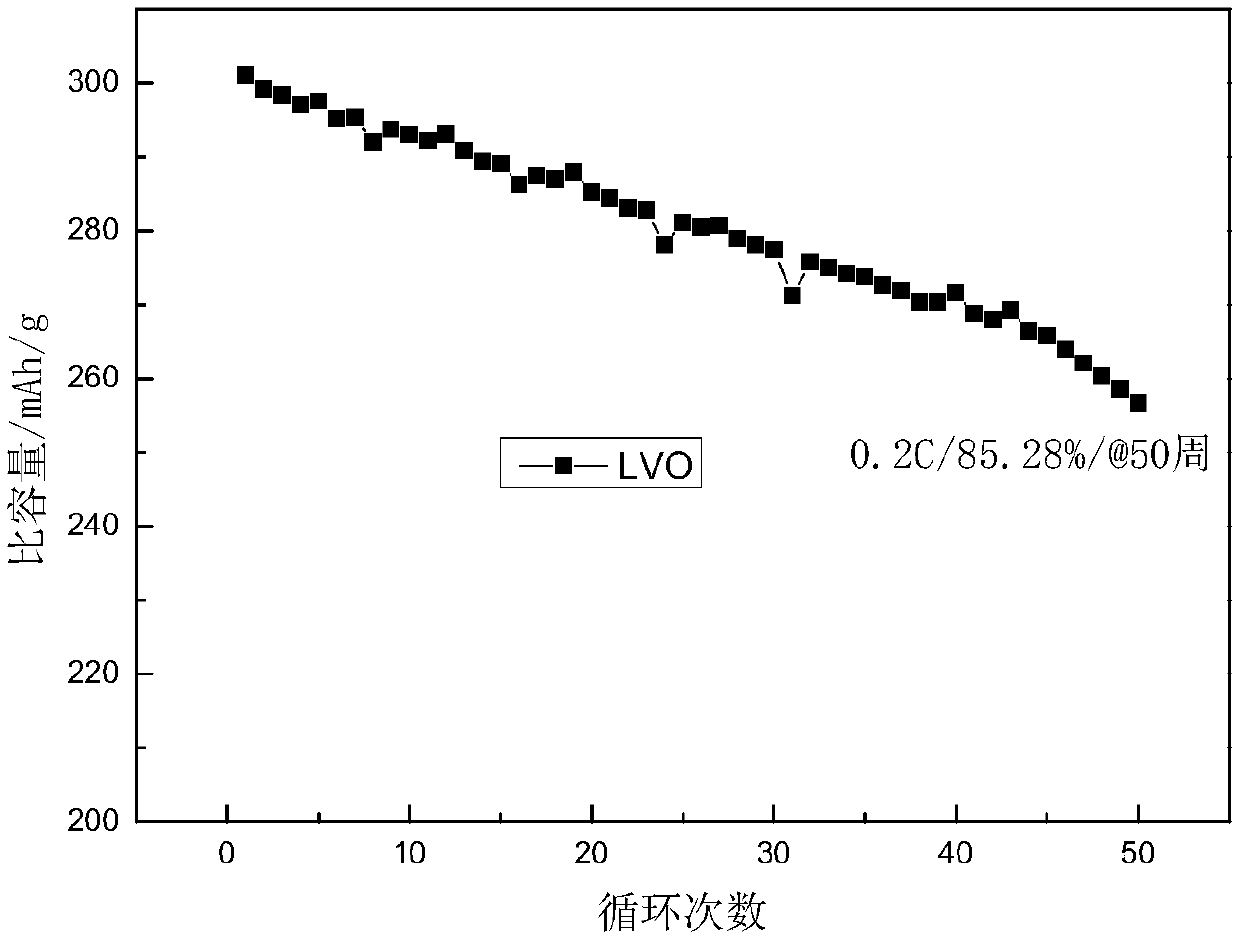

Image

Examples

Embodiment 1

[0024] (1) Pretreatment: Put the lithium hydroxide material in an oven and bake at 80°C for 8 hours, take it out and put it in a dry reagent bottle to seal it for later use;

[0025] (2) Lithium source active site control: put the dried lithium source material in step (1) into an atomic layer deposition (ALD) chamber at a temperature of 120 ° C, and then use ethanol as a pulsed gas source to the atomic layer deposition chamber After 30s in vivo, use high-purity nitrogen to blow off the excess pulse gas source to obtain a surface-passivated lithium hydroxide substrate;

[0026] (3) Raise the temperature of the ALD cavity containing the passivated lithium hydroxide substrate in step (2) to 200°C, and heat the ammonium metavanadate to its vapor pressure temperature of 145.8°C as the pulse gas source, and the pulse time is 50s after , purging with high-purity nitrogen for 100s; then using oxygen as a pulse gas source, the pulse time is 30s, and then purging with high-purity nitrog...

Embodiment 2

[0033] (1) Pretreatment: Put the lithium acetate material in an oven and bake at 100°C for 10 hours, take it out and put it in a dry reagent bottle to seal it for later use;

[0034] (2) Lithium source active site control: put the dried lithium acetate material in step (1) into an atomic layer deposition (ALD) chamber at a temperature of 140°C; use formaldehyde as a pulse gas source for 50s, and then use high-purity nitrogen gas Blow off the excess pulse gas source to obtain a surface-passivated lithium acetate substrate;

[0035] (3) Raise the temperature of the ALD cavity carrying the passivated lithium acetate substrate in step (2) to 200°C, heat the ammonium metavanadate to its vapor pressure temperature of 145.8°C, use it as a pulse gas source, pulse for 80s, and use high Pure nitrogen is purged for 100s; then oxygen is used as the pulse gas source, and after the pulse is 50s, it is purged with high-purity nitrogen for 100s to obtain a cycle of uniform deposition of vanad...

Embodiment 3

[0040] (1) Pretreatment: Put the lithium hydroxide material in an oven and bake at 90°C for 10 hours, take it out and put it into a dry reagent bottle to seal it for later use;

[0041] (2) Lithium source active site control: put the dried lithium source material in step (1) into the atomic layer deposition (ALD) chamber, heat the chamber temperature to 160°C, use ethanol as the pulse gas source, and use high Pure nitrogen is used as the carrier gas, and the pulse time of the pulse gas source is 30s, and then the excess pulse gas source is blown off with high-purity nitrogen gas to obtain a surface-passivated lithium hydroxide substrate;

[0042] (3) Raise the temperature of the ALD chamber containing the passivated lithium hydroxide substrate in step (2) to 200°C, and heat the ammonium metavanadate to its vapor pressure temperature of 145.8°C, as a pulse gas source, and the pulse time is 50s 1. Purging with high-purity nitrogen for 100s; then using oxygen as a pulse gas sourc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com