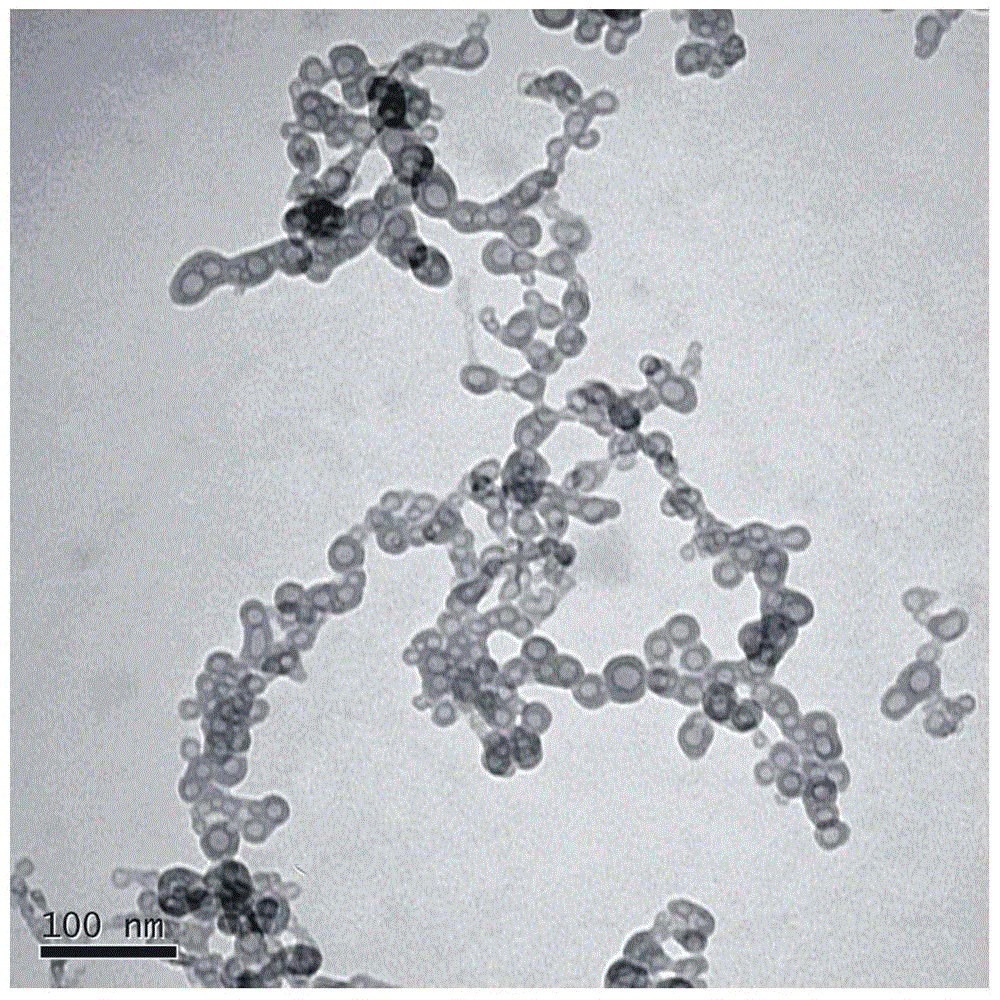

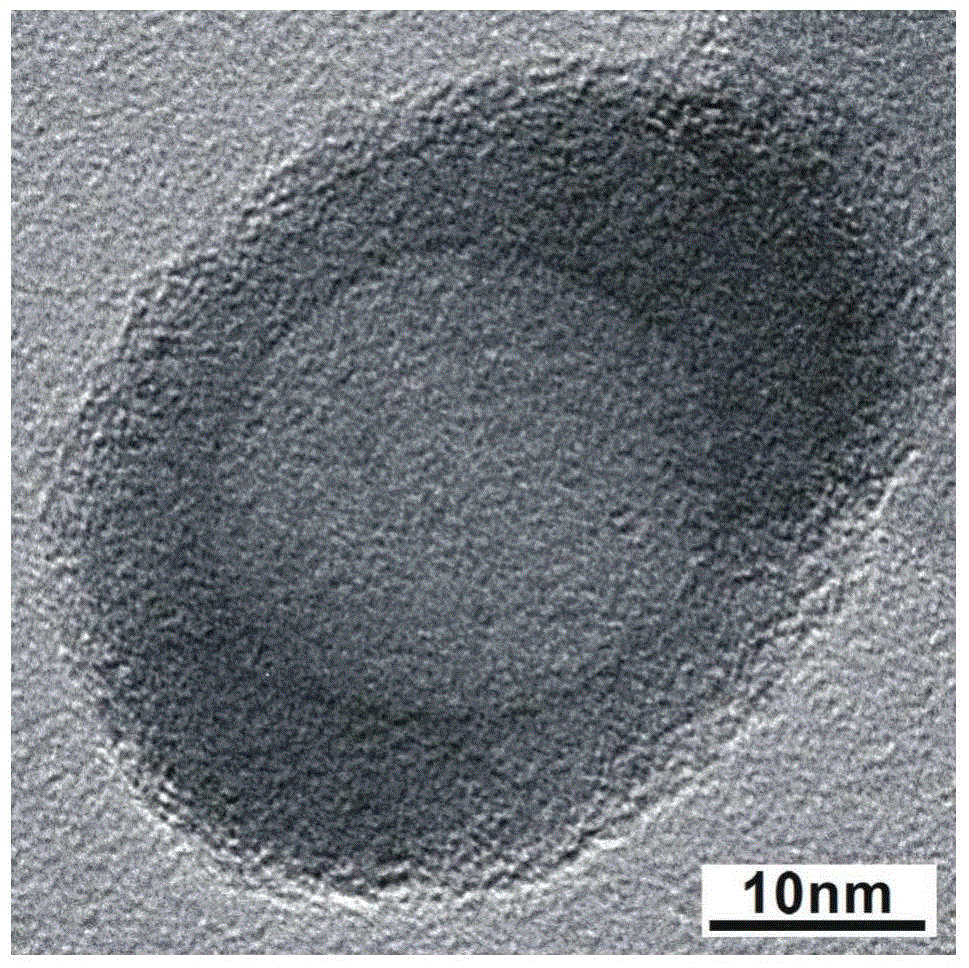

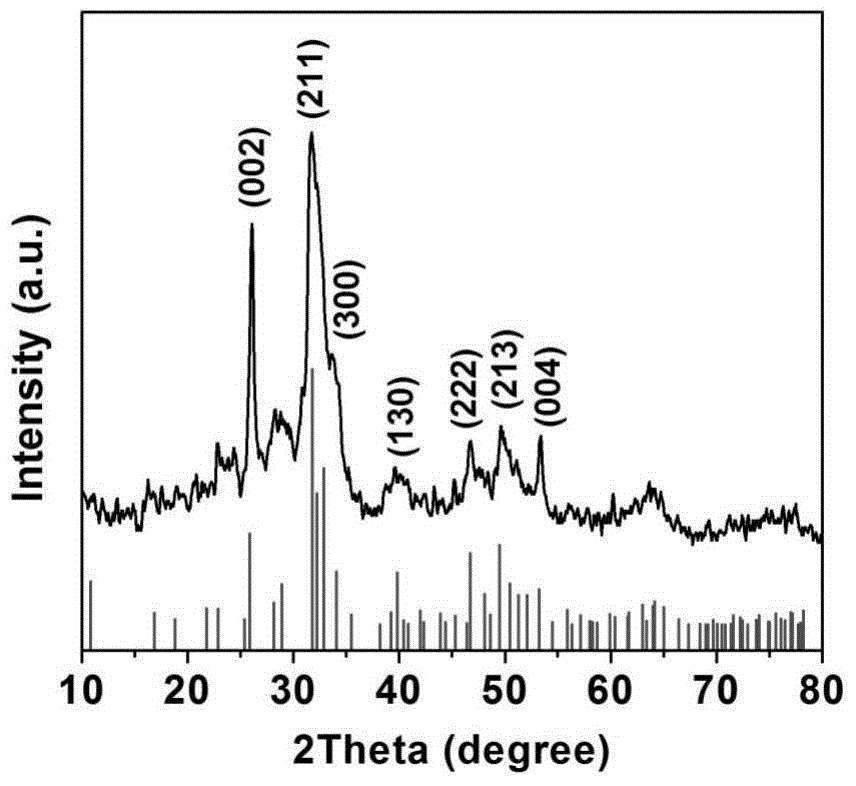

A nano-spherical hollow hydroxyapatite powder and its preparation method

A hollow hydroxyapatite and spherical technology, which is applied in the field of biomedical material engineering, can solve the problems of rough surface and limited application range, and achieve the effect of smooth surface, uniform size and perfect crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 0.0607g of calcium stearate, 2mL of oleic acid and 20mL of toluene into the reaction vessel, put it into the stirring rotor, raise the temperature to 100°C under magnetic stirring, and keep stirring at this temperature until the solution is optically transparent (time about 2min) , Stop heating then, make it cool to room temperature, form the calcium stearate solution that calcium ion concentration is 0.005mol / L. 0.0228g sodium phosphate dodecahydrate (Na 3 PO 4 ) was dissolved in 20mL deionized water to make sodium phosphate (Na3 PO 4 ) aqueous solution. The prepared sodium phosphate (Na 3 PO 4 ) aqueous solution into the prepared calcium stearate solution (the Ca / P molar ratio of the reaction system is 1.67), after the sodium phosphate aqueous solution is added dropwise, continue to stir at a stirring rate of 800r / min for 2min and then stop stirring, and then at 60°C React in a water bath for 10 hours; after the reaction time expires, age at room temperature ...

Embodiment 2

[0038] Add 0.0607g of calcium stearate, 2mL of oleic acid and 20mL of toluene into the reaction vessel, put in the stirring rotor, heat to 70°C under magnetic stirring, and keep stirring at this temperature until the solution is optically transparent (time about 2min) , Stop heating then, make it cool to room temperature, form the calcium stearate solution that calcium ion concentration is 0.005mol / L. 0.0228g sodium phosphate dodecahydrate (Na 3 PO 4 ) was dissolved in 20mL deionized water to make sodium phosphate (Na 3 PO 4 ) aqueous solution. The prepared sodium phosphate (Na 3 PO 4 ) aqueous solution into the prepared calcium stearate solution (the Ca / P molar ratio of the reaction system is 1.67), after the sodium phosphate aqueous solution is added dropwise, continue to stir at a stirring rate of 700r / min for 2min and then stop stirring, then at 40°C React in a water bath for 10 hours; after the reaction time expires, age at room temperature for 20 hours and break th...

Embodiment 3

[0041] Add 0.0607g of calcium stearate, 2mL of oleic acid and 20mL of toluene into the reaction vessel, put it into the stirring rotor, raise the temperature to 80°C under magnetic stirring, and keep stirring at this temperature until the solution is optically transparent (time about 2min) , Stop heating then, make it cool to room temperature, form the calcium stearate solution that calcium ion concentration is 0.005mol / L. 0.0228g sodium phosphate dodecahydrate (Na 3 PO 4 ) was dissolved in 20mL deionized water to make sodium phosphate (Na 3 PO 4 ) aqueous solution. The prepared sodium phosphate (Na 3 PO 4 ) aqueous solution into the prepared calcium stearate solution (the Ca / P molar ratio of the reaction system is 1.67), after the sodium phosphate aqueous solution is added dropwise, continue to stir at a stirring rate of 600r / min for 2min and then stop stirring, and then at 80°C React in a water bath for 10 hours; after the reaction time expires, age at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com