A kind of nano-array bismuth vanadate powder for sterilization and its preparation and application

A technology of arraying bismuth vanadate and powder, applied in the field of photocatalytic functional materials, can solve the problems of not fundamentally solving the interface electron flow and the control of photoacoustic electron separation and recombination, so as to solve the interface electron flow and photoacoustic separation and recombination. The effect of electron separation and recombination, excellent performance, and excellent visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

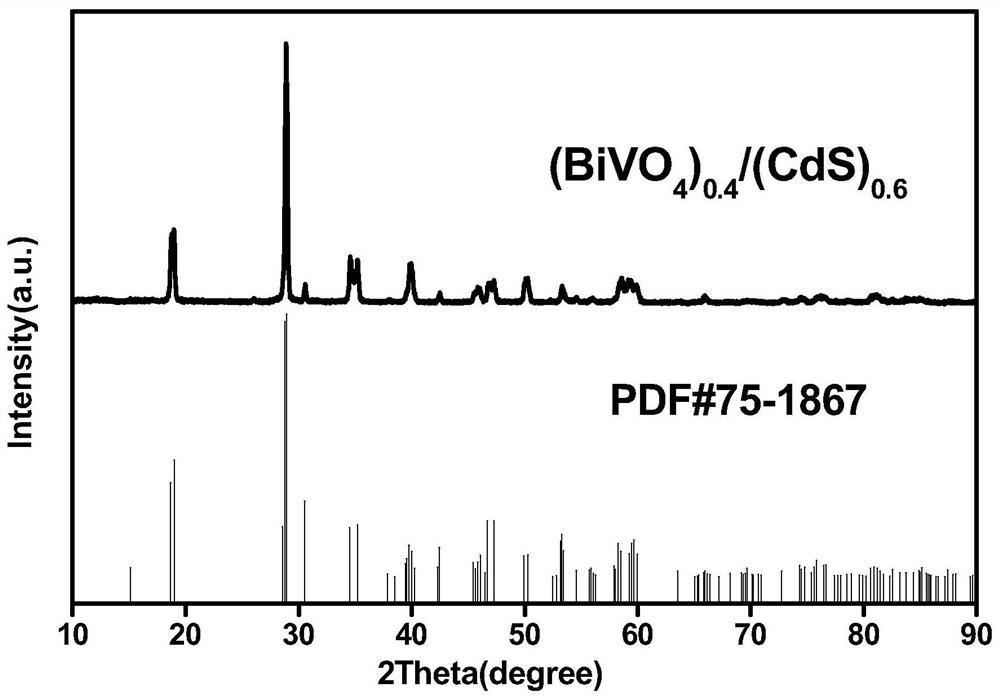

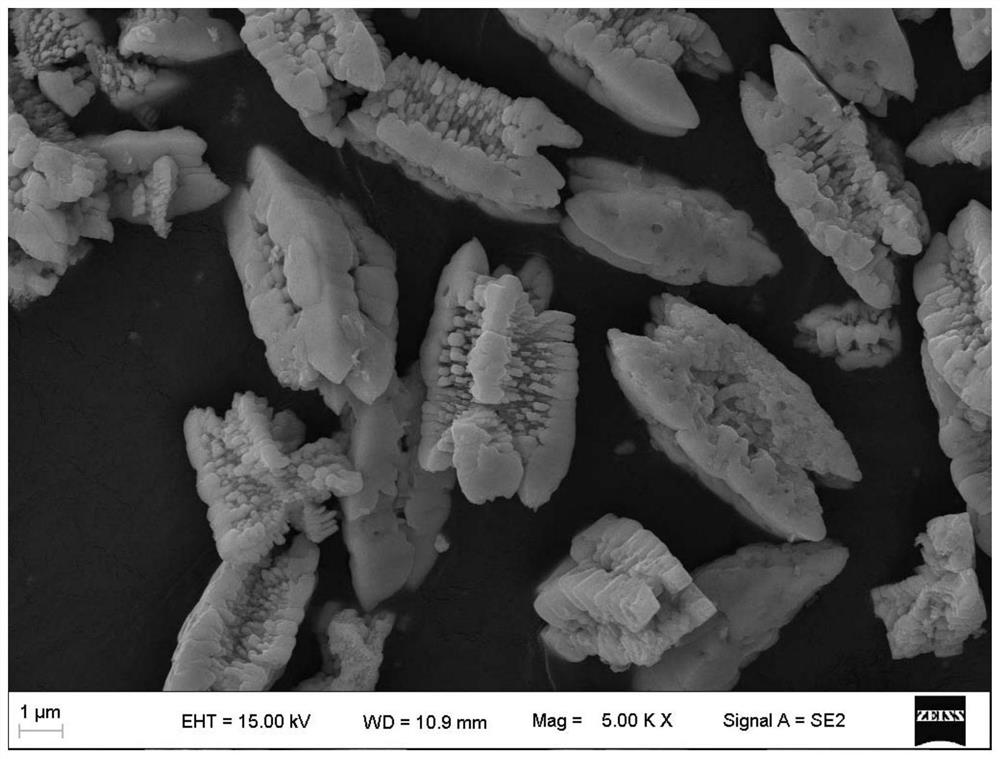

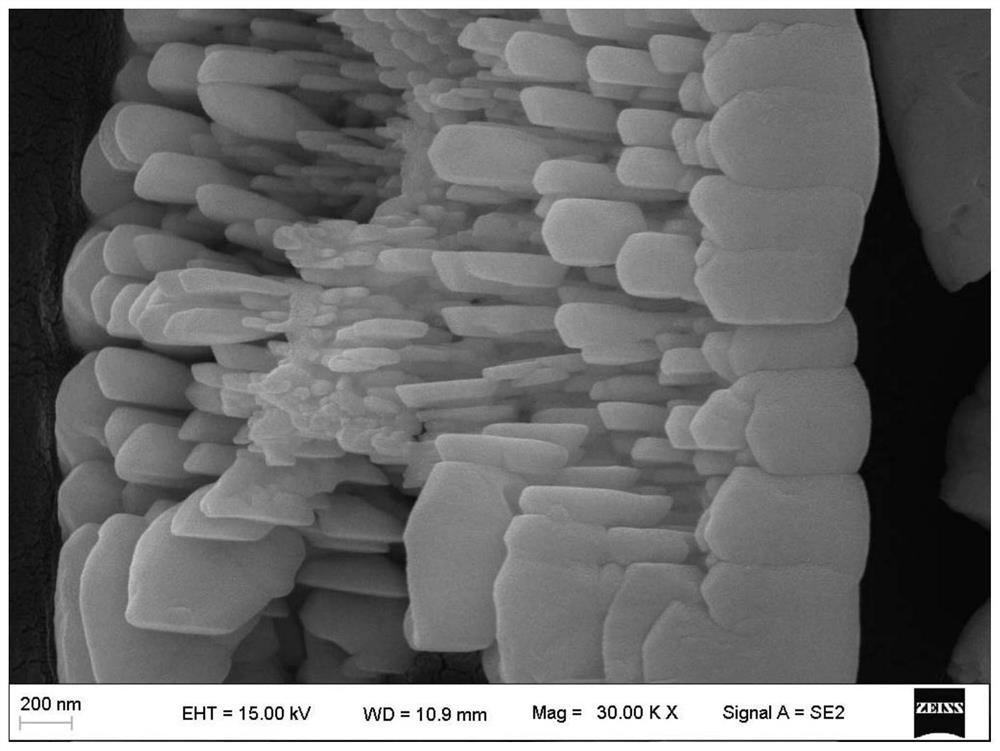

[0035] A kind of bismuth vanadate powder for sterilization nano array, its general formula is: (BiVO 4 ) x / (CdS) y , 0<x:y<1.

[0036] Described a kind of preparation method for sterilizing nano-array bismuth vanadate powder comprises the following steps:

[0037] Step 1: Weigh 0.6mmol of bismuth nitrate and dissolve it in a certain amount of ethylene glycol solution (the volume of ethylene glycol is 20 times the molar amount of bismuth nitrate), add 0.1gCATB, and stir to obtain solution A;

[0038] Step 2: Weigh 0.6mmol NH 4 VO 3 Dissolve in deionized water (the volume of deionized water is 15 times the molar amount of bismuth nitrate), stir at 500r / min for 0.5h, and put the dissolved liquid into the extraction tube of the Soxhlet extractor. Slowly pour solution A into the flask at the upper end of the Soxhlet extractor, reflux at 100°C for 0.5 hour, and cool to obtain solution B.

[0039] Step 3: Weigh 0.9 mmol cadmium nitrate and dissolve it in deionized water (the v...

Embodiment 2

[0043] A kind of bismuth vanadate powder for sterilization nano array, its general formula is: (BiVO 4 ) x / (CdS) y , 0<x:y<1.

[0044] Described a kind of preparation method for sterilizing nano-array bismuth vanadate powder comprises the following steps:

[0045] Step 1: Weigh 0.5mmol bismuth acetate and dissolve it in a certain amount of ethylene glycol solution (the volume of ethylene glycol is 15 times the molar amount of bismuth acetate), add 0.1gCATB, and stir to obtain solution A;

[0046] Step 2: Weigh 0.5mmol NH 4 VO 3 Dissolve in deionized water (the volume of deionized water is 10 times the molar amount of bismuth acetate), stir at 600r / min for 0.5h, and put the dissolved liquid into the extraction tube of the Soxhlet extractor. Slowly pour solution A into the flask at the upper end of the Soxhlet extractor, reflux at 80°C for 1 hour, and cool to obtain solution B.

[0047] Step 3: Weigh 1mmol cadmium acetate and dissolve it in deionized water (the volume of ...

Embodiment 3

[0051] A kind of bismuth vanadate powder for sterilization nano array, its general formula is: (BiVO 4 ) x / (CdS) y , 0

[0052] Described a kind of preparation method for sterilizing nano-array bismuth vanadate powder comprises the following steps:

[0053] Step 1: Weigh 1.2 mmol of bismuth phosphate and dissolve it in a certain amount of ethylene glycol solution (the volume of ethylene glycol is 10 times the molar amount of bismuth phosphate), add 0.1g CATB, and stir to obtain solution A;

[0054] Step 2: Weigh 1.2mmol NH 4 VO 3 Dissolve in deionized water (the volume of deionized water is 20 times the molar amount of bismuth phosphate), stir at 800r / min for 0.5h, and put the dissolved liquid into the extraction tube of the Soxhlet extractor. Slowly pour solution A into the flask at the upper end of the Soxhlet extractor, reflux at 90°C for 1 hour, and cool to obtain solution B.

[0055] Step 3: Weigh 1.8 mmol of cadmium phosphate and dissolve it in deionized wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com