Vaporization chamber of methanol fuel cell

A methanol fuel cell and vaporization chamber technology, applied in the vaporization chamber field, can solve the problems of low efficiency, long restart time, large temperature difference, etc., and achieve the effects of expanding the application range, accelerating the starting speed, and ensuring the sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

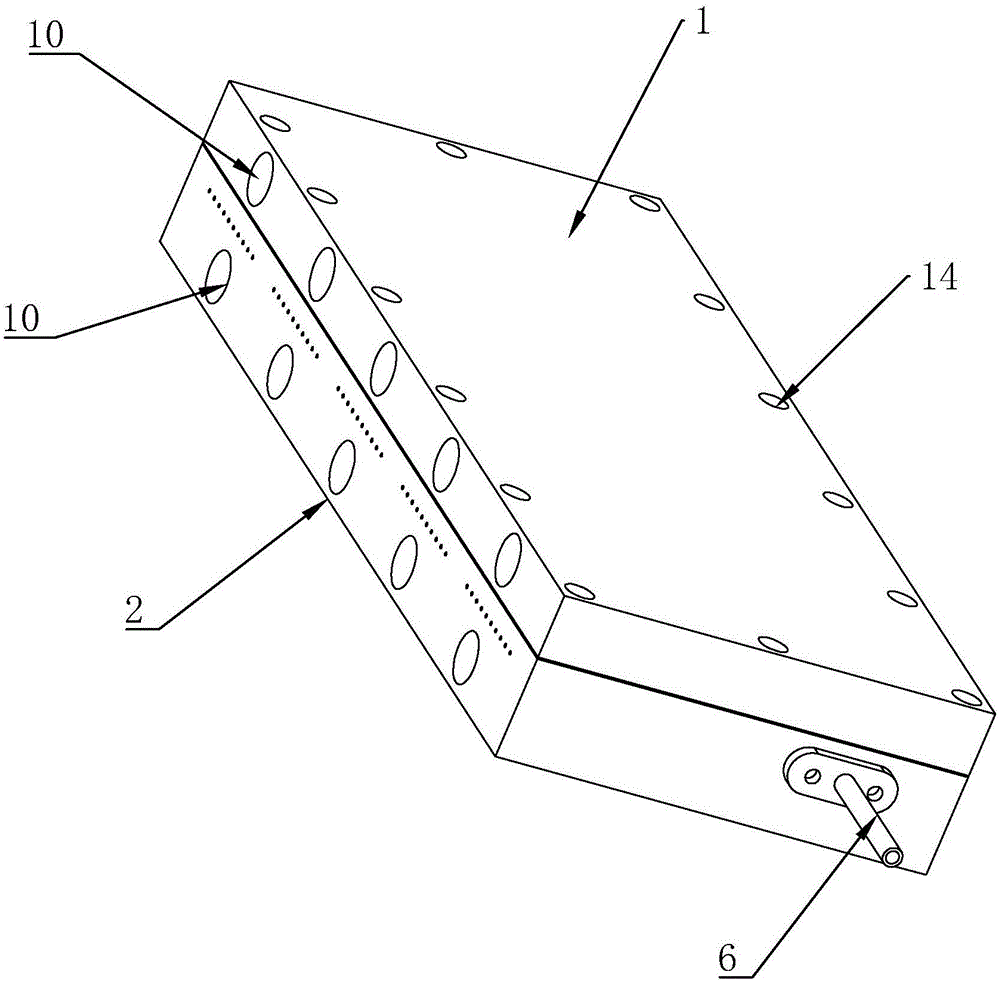

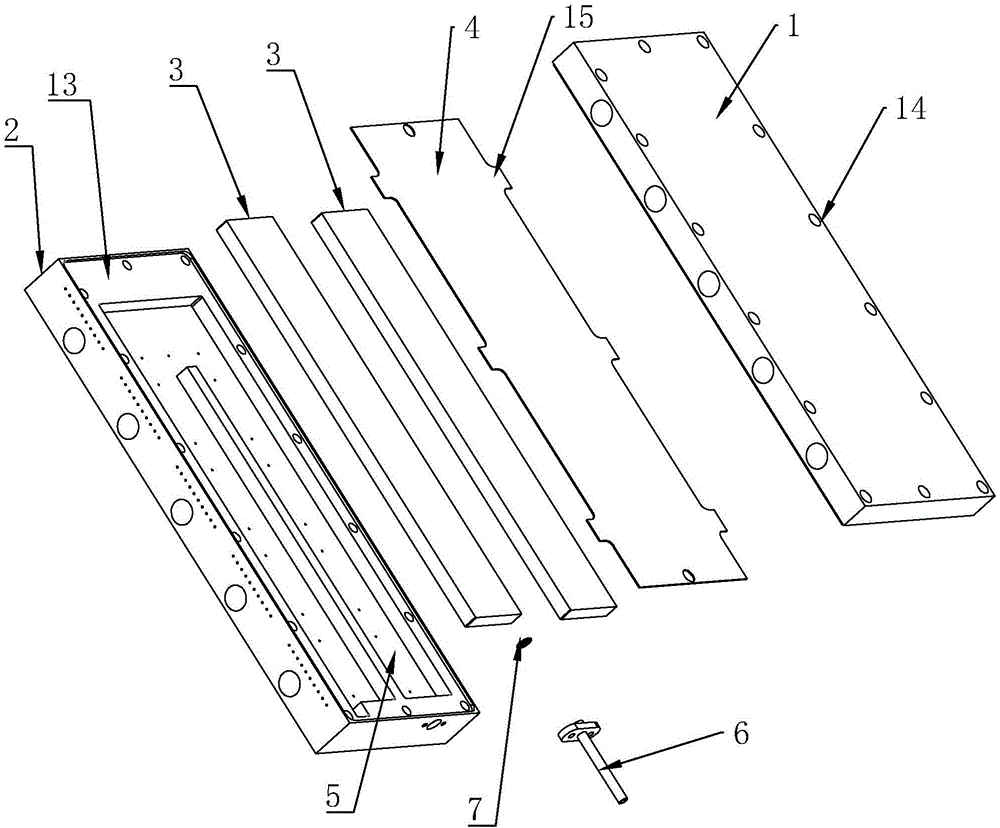

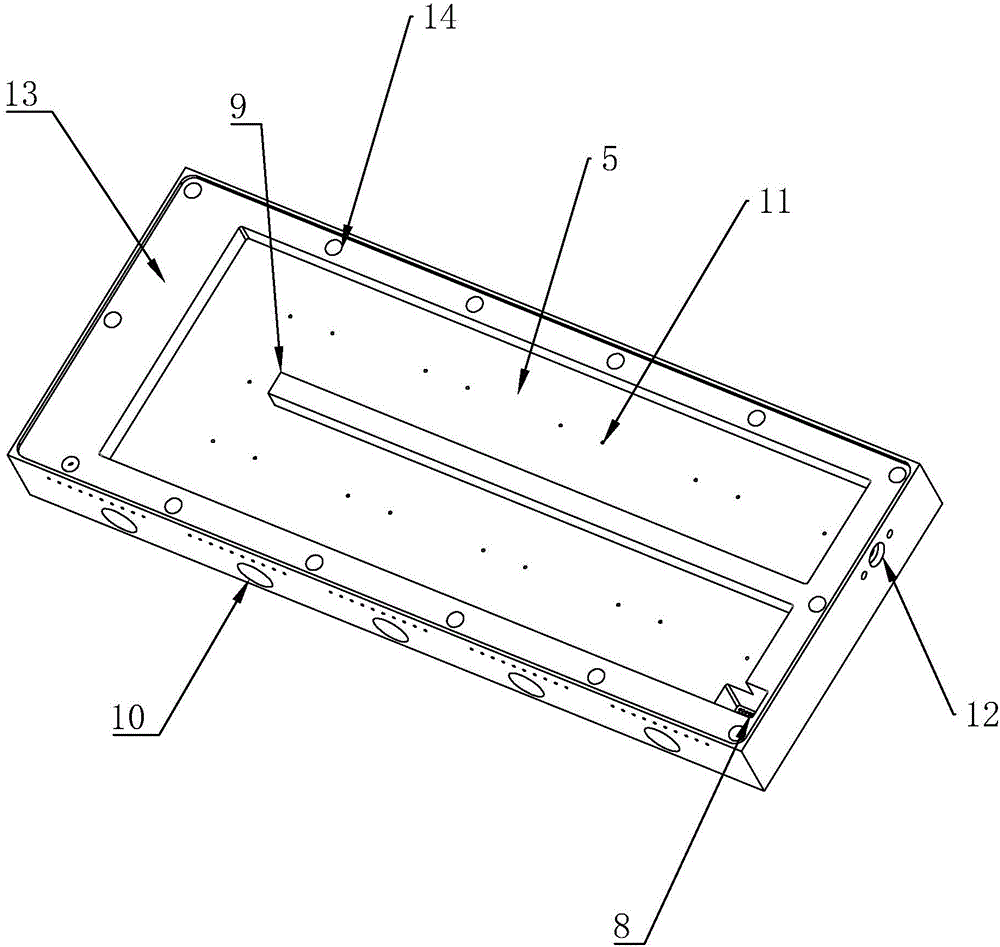

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] like figure 1 As shown, a vaporization chamber of a methanol fuel cell includes an upper cover plate 1, a lower cover plate 2, and a pure aluminum gasket 4 arranged between the upper cover plate 1 and the lower cover plate 2, and the lower cover plate 2 is A U-shaped flow channel 5 is provided, and the two ends of the U-shaped flow channel 5 are respectively provided with a methanol water inlet 12 and a gas outlet 8, and a partition 9 is arranged in the middle of the U-shaped flow channel 5, and the U-shaped flow channel The inlet of 5 is connected with methanol water inlet pipe 6, and the upper cover plate 1 and the lower cover plate 2 are provided with heating holes 10 for placing power supply heating rods.

[0018] In the vaporization chamber of a methanol fuel cell of the present invention, the flow channel is arranged in a U shape as a whole, and the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com