Microstrip Isolator Bonding Fixture

A technology of isolator and microstrip, which is applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problem of consistency, production efficiency is difficult to meet the potential needs of microstrip isolators, and the consistency of microstrip isolators is limited. The accuracy of the joint position, the inability to achieve the consistency of the permanent magnet bonding, etc., achieve good stability and position consistency, easy processing, and prevent misalignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

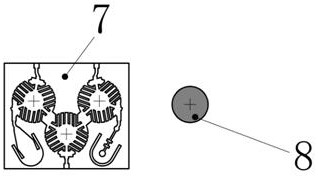

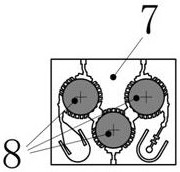

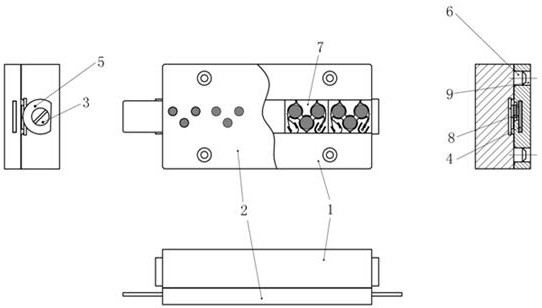

[0027] see Figure 3-7 , a bonding fixture for a microstrip isolator, comprising a microstrip substrate fixing module and a permanent magnet fixing module,

[0028] Wherein, the microstrip substrate fixed module, see Figure 4 with 5 , including a microstrip substrate 7, a substrate placement plate 1 for placing the microstrip substrate 7, a limiting block 5 and a locking screw 3 for limiting the microstrip substrate 7, and a positioning pin 6, limiting Block 5 is a polytetrafluoroethylene limit block;

[0029] During operation, put the microstrip substrate 7 into the chute 11 of the substrate placement plate 1 in the same direction, and prevent the microstrip substrate 7 from slipping out by rotating the polytetrafluoroethylene limit block 5 and the locking screw 3, and fix it well The relative position of the microstrip substrate 7 and the positioning pin 6 is a fixed value, which can better be docked with the permanent magnet fixed module;

[0030] The permanent magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com