Collecting sliding ring grinding device built in electric device and electric device

A technology for electrical equipment and current collection, which is applied in the directions of electrical components, current collector maintenance, circuit/collector components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

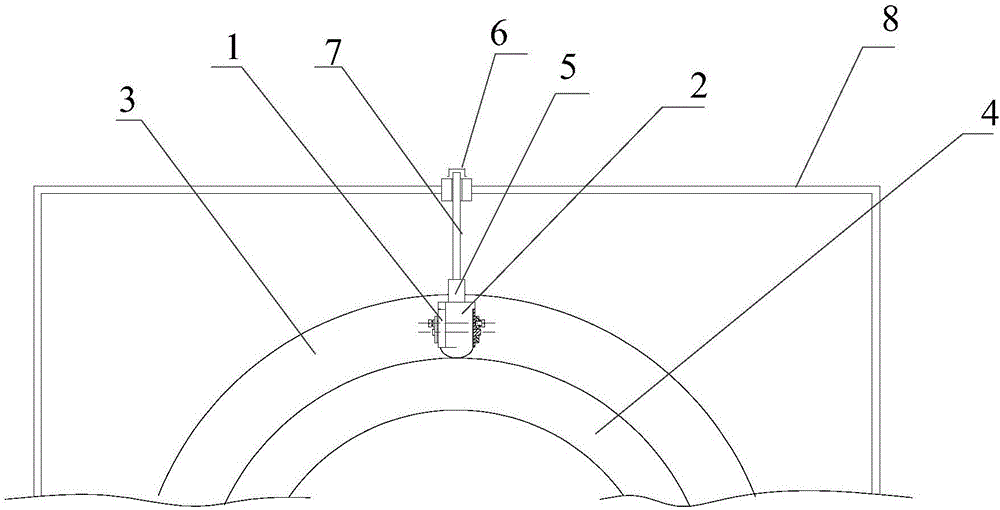

[0028] This embodiment provides a grinding device for the collector slip ring 4, the grinding device is built into the rotating electrical equipment, such as figure 1 As shown, the device includes: a clamping part 1, a grinding tool 2, and a pressing mechanism; wherein,

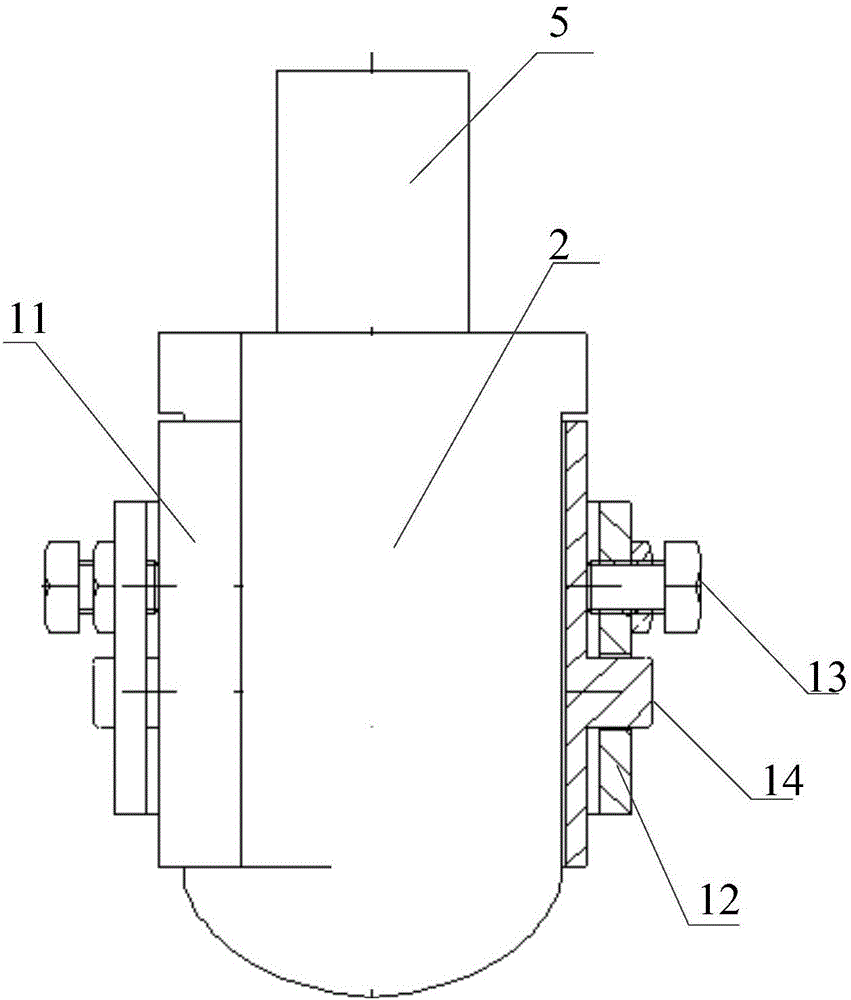

[0029] see figure 2 , the clamping part 1 is fixed on the fixed part 3 on the radially outer side of the collector slip ring 4 by bolts; the fixing part 3 may specifically include a conductive part, and the conductive part may include a current leading busbar, The current introducing bus bar is arranged outside the outer diameter of the collector slip ring 4 . Wherein, because the grinding device composed of the grinding tool 2 and the clamping part 1 is respectively connected to two equipotential conductive parts, there is no need for electrical insulation between the grinding tool 2 and the current introducing bus bar.

[0030] The clamping part 1 includes: an angle adjustment mechanism, and the angle ad...

Embodiment 2

[0043]Corresponding to Embodiment 1, this embodiment also provides an electrical equipment, the electrical equipment includes: a grinding device for the collector slip ring 4, and the grinding device is installed in the chamber of the collector slip ring 4 of the electrical equipment , specifically, as figure 1 As shown, the device includes: a clamping part 1, a grinding tool 2, and a pressing mechanism; wherein,

[0044] The clamping part 1 is fixed on the fixed part 3 on the radially outer side of the collector slip ring 4 by bolts; the fixed part 3 may specifically include a conductive part, and the conductive part may include a current leading busbar, so The current introduction busbar is arranged outside the outer diameter of the collector slip ring 4 . Wherein, because the grinding device composed of the grinding tool 2 and the clamping part 1 is respectively connected to two equipotential conductive parts, therefore, there is no need for electrical insulation between t...

Embodiment 3

[0058] Corresponding to Embodiment 2, when the rotating electrical equipment is the rotor excitation system of a large synchronous motor, the grinding device provided in Embodiment 1 can be used to grind the surface of the collector slip ring 4, as follows:

[0059] Such as figure 1 As shown, the device includes: a clamping part 1, a grinding tool 2, and a pressing mechanism; wherein,

[0060] The clamping part 1 is fixed on the fixed part 3 on the radially outer side of the collector slip ring 4 by bolts; the fixed part 3 may specifically include a conductive part, and the conductive part may include a current leading busbar, so The current introduction busbar is arranged outside the outer diameter of the collector slip ring 4 . Wherein, because the grinding device composed of the grinding tool 2 and the clamping part 1 is respectively connected to two equipotential conductive parts, there is no need for electrical insulation between the grinding tool 2 and the current intro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com