Long-distance intertidal zone submarine cable landing laying construction method and system

A technology for submarine cables and intertidal zones, applied in cable laying equipment and other directions, can solve problems such as large frictional resistance, large traction force, and large cable cross-section, and achieve the effect of reducing frictional resistance, speeding up laying speed, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Involving devices such as Figure 1-4 shown.

[0030] The working method for the laying of long-distance intertidal submarine cable landing includes the following steps:

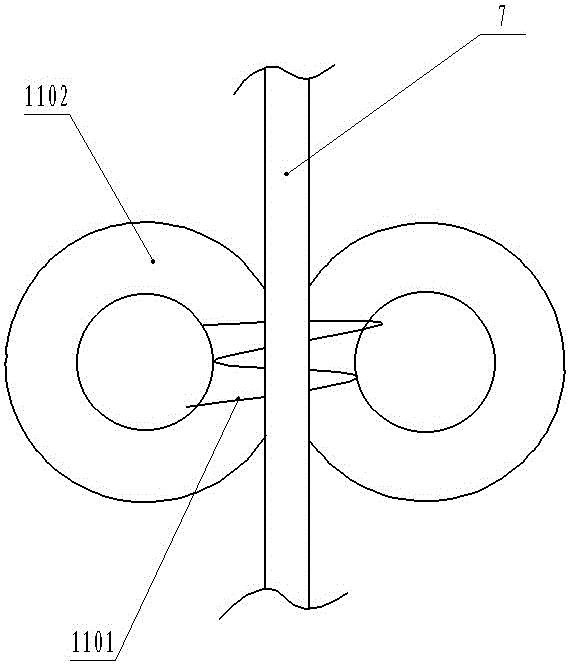

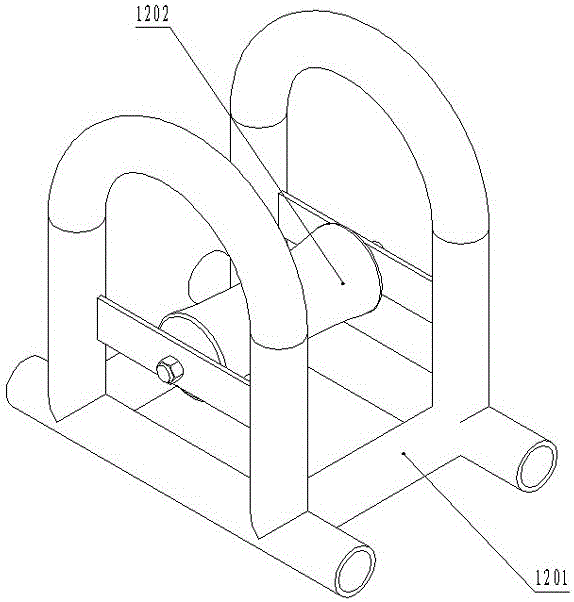

[0031] 1) Dig a transition ditch 3 in the transition area between the intertidal zone 4 and the submarine cable ship 1, and arrange the floating tire frame 11 in the transition ditch 3;

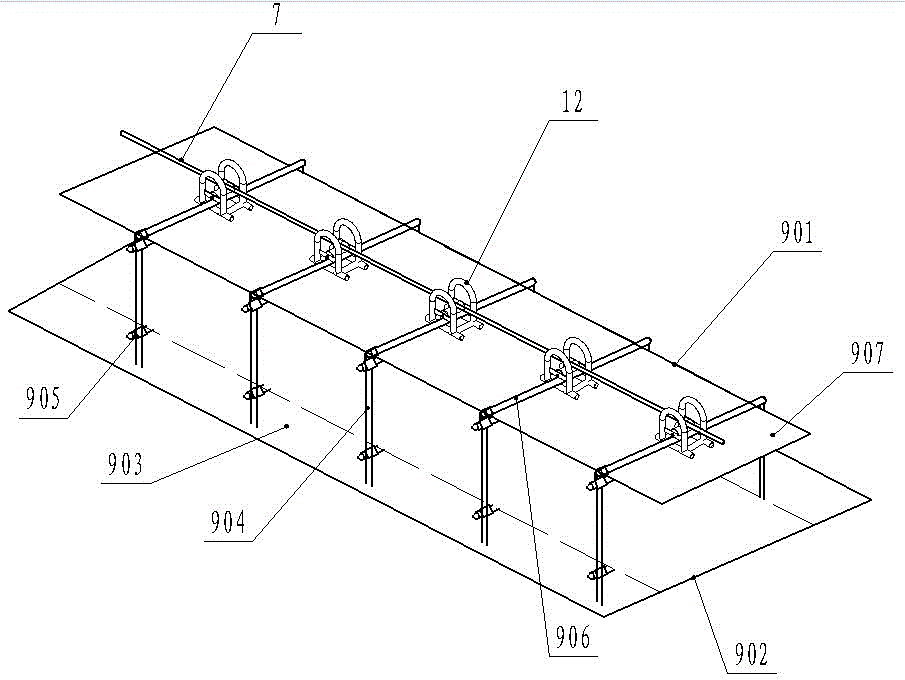

[0032] 2) Build double-layer scaffolding 9 from the front end of the transition ditch 3 to the direction of the substation 8;

[0033] 3) Set cable laying machines 5 one by one from the scaffold 9 at the front end of the transition ditch 3, and set a winch 6 in the cable outlet direction of each cable laying machine 5;

[0034] 4) A pulley 12 is arranged on the scaffold 9 along the direction of the cable 7, and the steering pulley is arranged on the scaffold 9 at the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com