Direct current electrical motor

A DC motor and casing technology, applied in the field of motors, can solve the problems of insufficient power of micro DC motors, etc., and achieve the effects of enhancing portability, reducing production costs, and eliminating waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

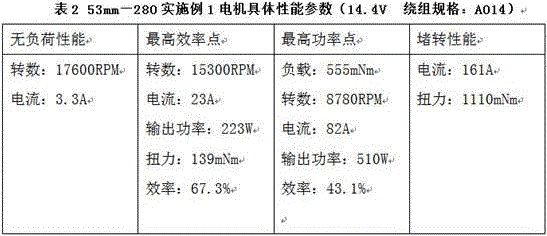

Embodiment 1

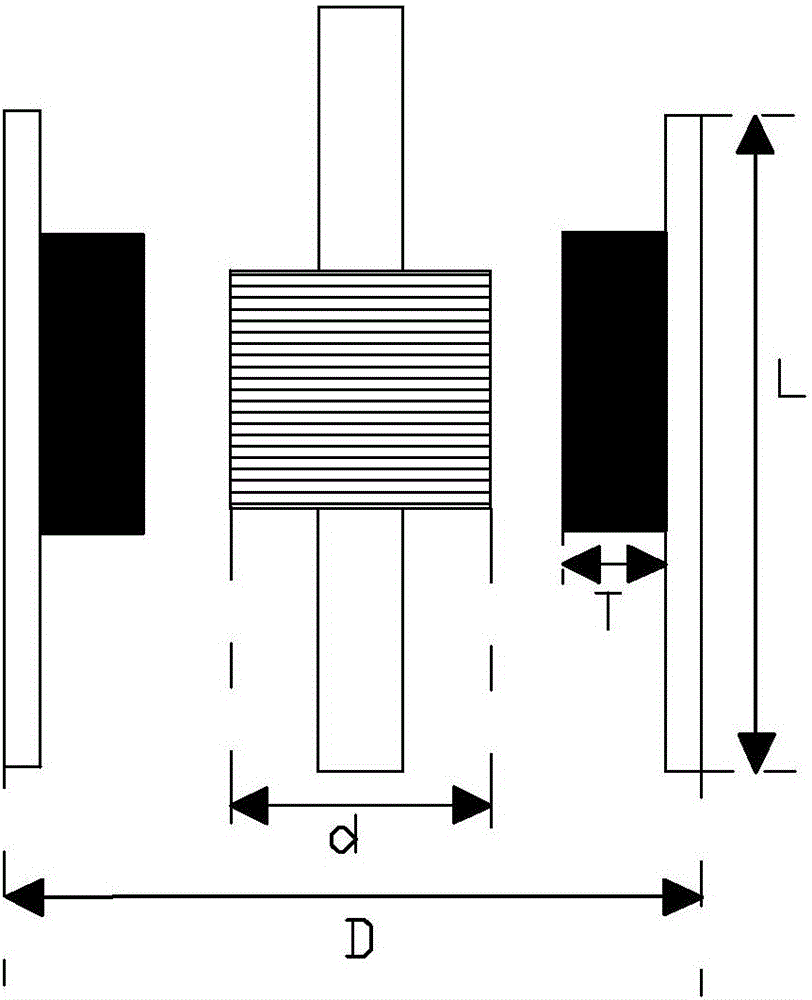

[0018] This embodiment includes a metal casing and a rotor, a stator and a rotating shaft arranged in the metal casing. The rotor is composed of laminated iron sheets and windings wound on the iron sheets. The stator is a number of paired magnets fixed on the inner surface of the metal casing. The paired magnets are close to the inner surface of the metal casing and are evenly distributed around. A ring-shaped yoke is arranged between the stator and the metal casing, and the yoke surrounds and evenly distributes on the inner surface of the metal casing. The rotor is arranged at the center of the surrounding pair of magnets, and is arranged in cooperation with the magnets. A rotating shaft is fixedly pierced through the center of the rotor, and when the rotor rotates under the action of magnetic force, the rotating shaft and the rotor rotate together. Such as figure 1 As shown, in this embodiment, let the radial thickness of the magnet be T, the axial thickness (diameter) of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap