Voice coil motor elastic piece and manufacturing method thereof

The technology of a voice coil motor and a manufacturing method, which is applied to manufacturing tools, electromechanical devices, laser welding equipment, etc., can solve the problems of unfavorable industrialized production, long lead time, and high cost, so as to save material costs and reduce lead time. , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

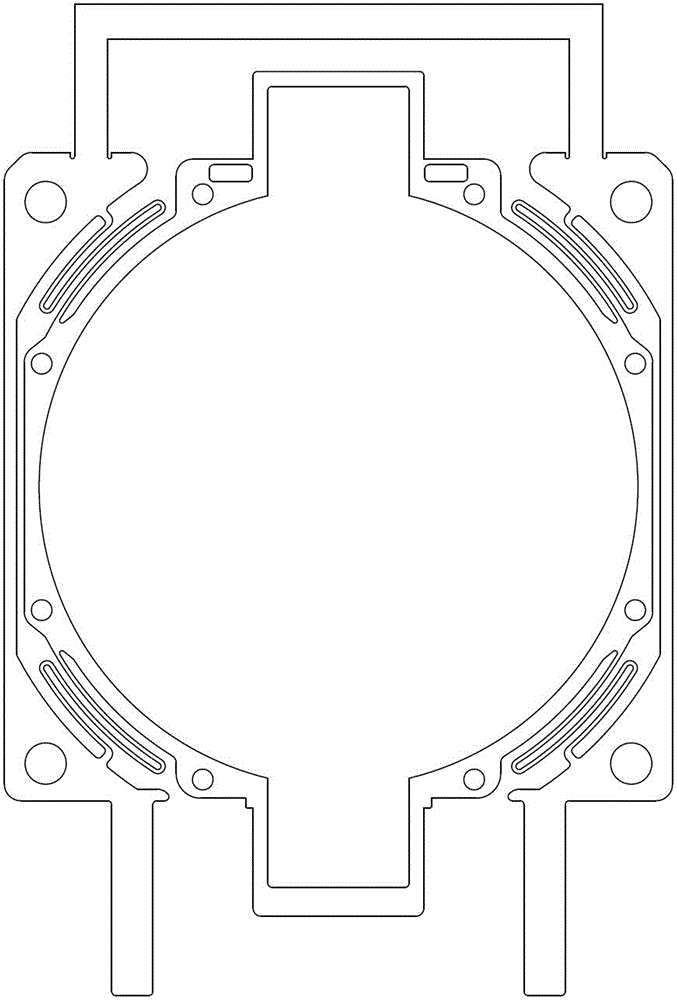

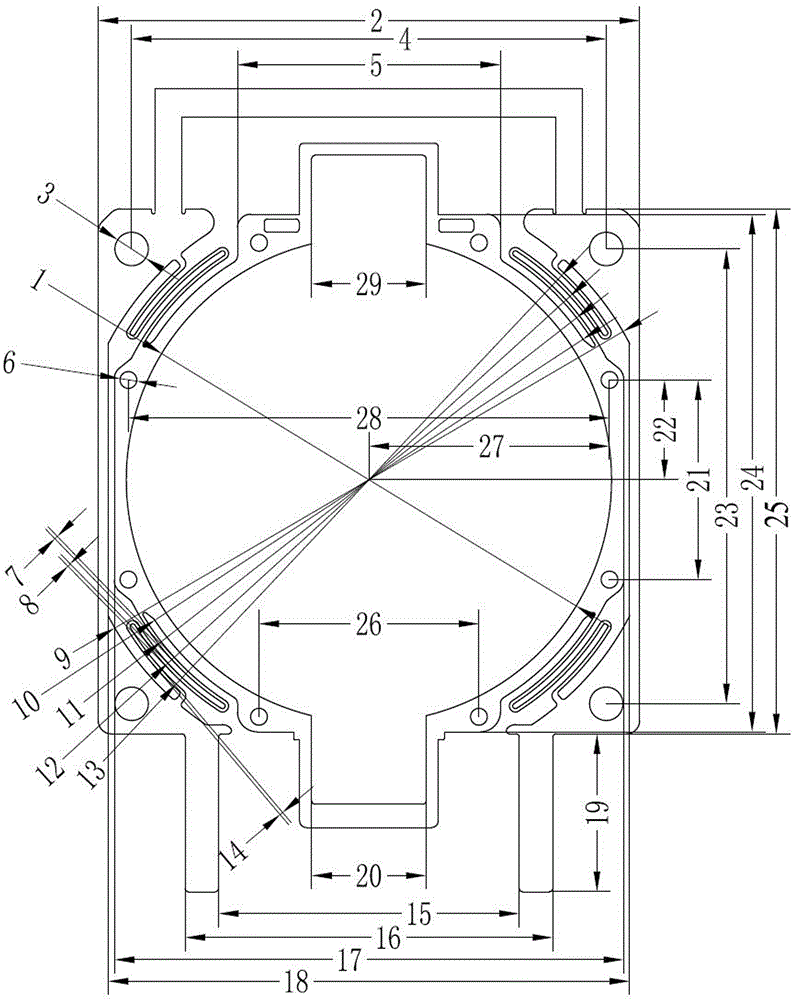

[0038] A method for making a shrapnel of a voice coil motor, specifically, etching a preset pattern on a substrate with a thickness of about 0.05 mm by using a laser etching machine to obtain such a figure 1 Voice coil motor shrapnel shown. Among them, the laser of the laser etching machine is a picosecond laser with a wavelength of 515nm, a pulse width of <10ps, and a repeatability of ±2um; the laser process parameters are as follows: power 40%, frequency 540KHZ, speed 450mm / s.

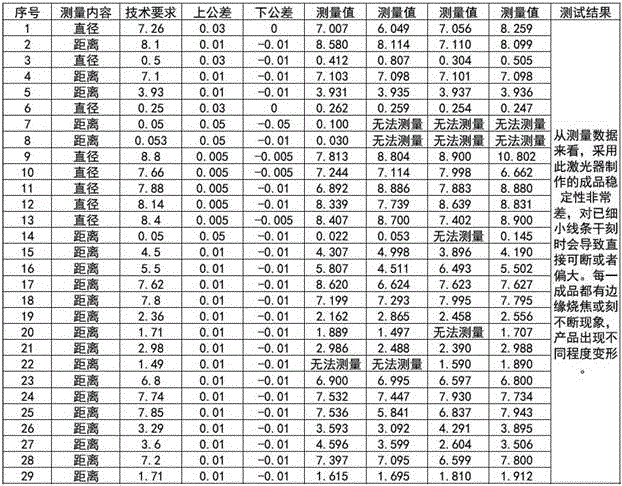

[0039] Measure the produced voice coil motor shrapnel by conventional detection methods, and select 29 points (such as figure 2 shown) were repeated 7 times, and some of the 29 points were the diameter of the hole, and some were the distance between two points. The specific measurement data are as follows.

[0040]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com