Conductive composition and electronic component using same

一种组合物、导电性的技术,应用在导电粘合剂、分散在不导电无机材料中的导电材料、导电材料等方向,能够解决接合界面剥离、接合部弹性模量变大、接合部变硬等问题,达到维持接合强度、弹性模量变小、抑制破裂的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

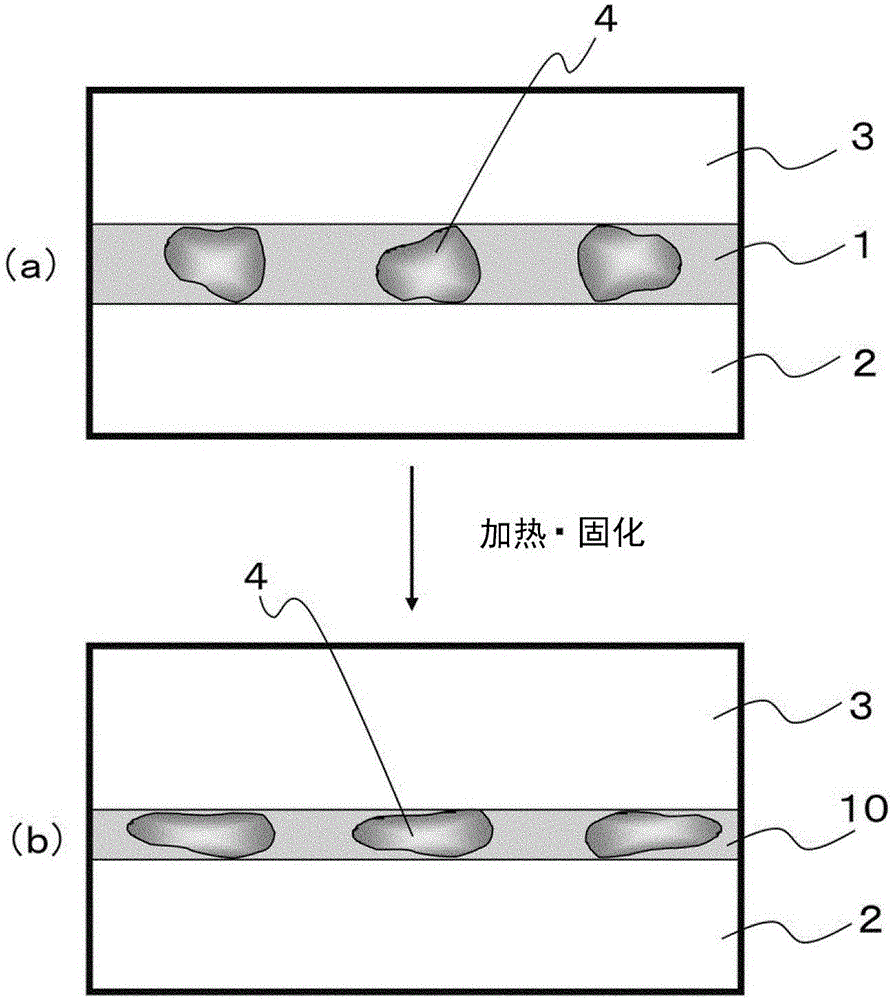

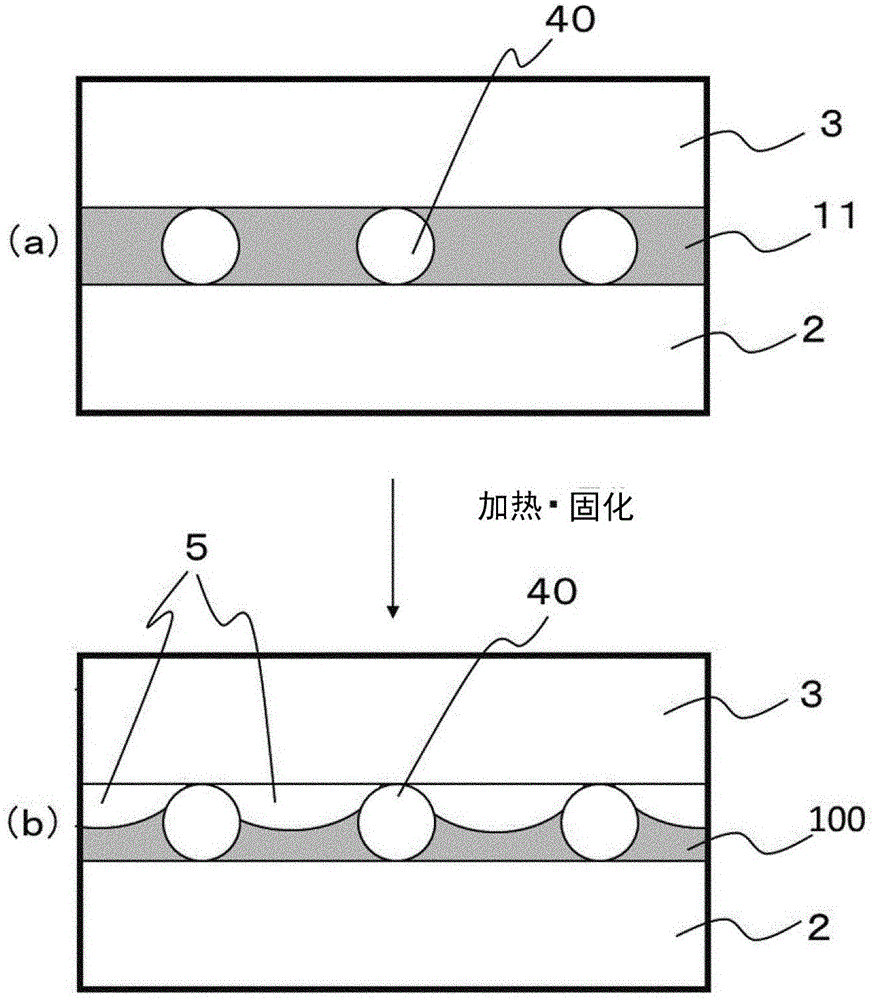

Method used

Image

Examples

Embodiment

[0119] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples.

[0120] Analysis in Examples was performed as follows.

[0121] (1) Determination of silver particles and metal particles

[0122] (1-1) Number average particle size

[0123] 0.5 g of silver fine particles or 0.5 g of metal particles was added to 50 cc of dispersion water (water containing 0.5% of AEROSOL manufactured by Beckmann Coulter), and dispersed for 5 minutes with an ultrasonic disperser. The number average particle diameter of the dispersed sample was measured by laser diffraction scattering particle size distribution measurement (LS230 manufactured by Beckmann Coulter). Based on the number basis, the number average particle diameter of the primary particles was obtained.

[0124] (1-2) Crystallite size

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com