Method for making sandwiches for pets

A production method and sandwich technology, which can be applied in the forming or processing of animal feed, application, animal feed, etc., can solve problems such as single taste and smell of products, pet bad breath and oral diseases, easy to rub/scratch gums, etc., to achieve a high level The effect of rich feeling, improvement of hair removal phenomenon, and avoidance of nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of preparation method that pet eats sandwich, comprises the following steps:

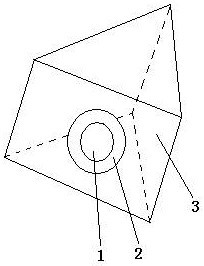

[0031] (1) Outer layer ( figure 1 Shown in 3, the following examples are the same) Production: arrange fresh chicken breasts, including cleaning, draining and weighing 100 parts; chop and mix the prepared fresh chicken breasts, and process them into minced meat; mince fresh chicken breasts Put the chicken breast in a blender and stir, slowly sprinkle in ingredient A, stir for 4 minutes, slowly sprinkle in ingredient B, stir for 7 minutes to a uniform state, and make the uniform mixture into a square patty with a side length of 8cm and a thickness of 3cm, as material one;

[0032] (2) middle layer ( figure 1 Shown 2, the same as in the following examples) Production: arrange the deboned fish raw materials, including thawing, washing, draining and weighing 100 parts; chop and mix the prepared deboned fish raw materials, and process them into minced meat; Put the deboned ...

Embodiment 2

[0045]Embodiment 2: a kind of preparation method that pet eats sandwich, comprises the following steps:

[0046] (1) Production of the outer layer: arrange fresh beef, including thawing, washing, draining and weighing 100 parts; chop and mix the prepared fresh beef, and process it into minced meat; put the minced fresh beef in a blender Stir, slowly sprinkle in ingredient A, stir for 3 minutes, slowly sprinkle in ingredient B, stir for 5 minutes to a uniform state, make the uniform mixture into a square patty with a side length of 6cm and a thickness of 2cm, as ingredient 1;

[0047] (2) Middle layer production: Arranging the deboned fish raw materials, including thawing, washing, draining and weighing 100 parts; chopping and mixing the prepared deboned fish raw materials into minced meat; placing the minced deboned fish raw materials in Stir in a blender, slowly sprinkle in ingredient C, stir for 3 minutes, add ingredient D, stir for 5 minutes until uniform, and use it as ing...

Embodiment 3

[0060] Embodiment 3: a kind of preparation method that pet eats sandwich, comprises the following steps:

[0061] (1) Production of the outer layer: Arrange fresh pork, including thawing, washing, draining and weighing 100 parts; chop and mix the arranged fresh pork, and process it into minced meat; put the minced fresh pork in a blender Stir, slowly sprinkle in ingredient A, stir for 5 minutes, slowly sprinkle in ingredient B, stir for 10 minutes to a uniform state, and make the uniform mixture into a square patty with a side length of 10cm and a thickness of 4cm, as ingredient 1;

[0062] (2) Middle layer production: Arranging the deboned fish raw materials, including thawing, washing, draining and weighing 100 parts; chopping and mixing the prepared deboned fish raw materials into minced meat; placing the minced deboned fish raw materials in Stir in a blender, slowly sprinkle in ingredient C, stir for 5 minutes, add ingredient D, stir for 10 minutes until uniform, and use i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com