Hot compress padding composition and preparation method thereof, hot compress eye patch and preparation method thereof

A technology for filling composition and eye mask, applied in the field of hot compress eye mask and preparation thereof, hot compress filling composition and preparation field, can solve the problems of long-term moisturizing of eyes, no effect, insignificant effect, etc., to relieve sleep problems and improve eye inflammation , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

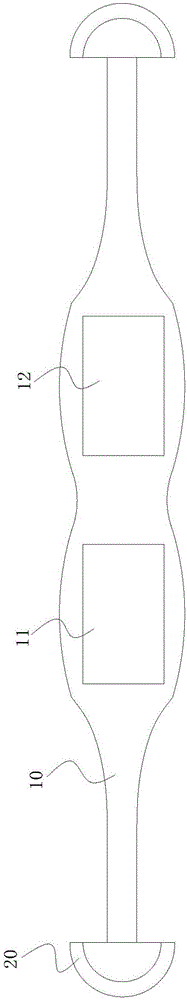

Image

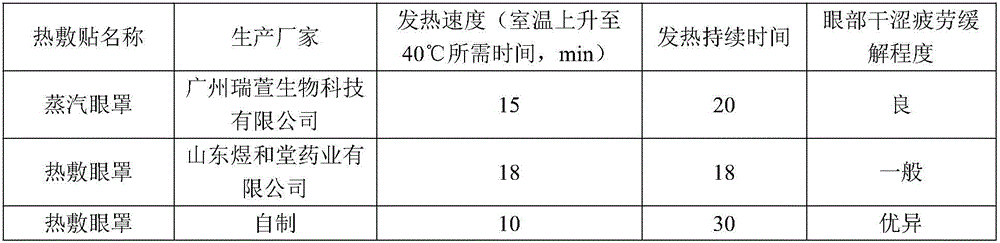

Examples

Embodiment 1

[0033] The hot compress filling composition comprises the following components by mass percentage:

[0034] Iron powder 20%, zinc powder 35%, activated carbon 8%, vermiculite 8%, water 16%, sodium chloride 3%, essential oil 7%, super absorbent resin 3%.

[0035] A preparation method of a hot compress eye mask comprising the above hot compress filling composition, comprising the following steps:

[0036] 1) Prepare materials according to the following mass percentages: 20% iron powder, 35% zinc powder, 8% activated carbon, 8% vermiculite, 16% water, 3% sodium chloride, 7% essential oil, and 3% superabsorbent resin.

[0037] 2) Put sodium chloride into water to dilute and dissolve to obtain a diluent for later use, pour activated carbon and superabsorbent resin into a blender and stir for 3 minutes, then add the diluent to the blender and stir for 10 minutes, then add zinc powder and stir for 5 minutes to obtain a mixed liquid;

[0038] 3) Pass the mixed solution through a vib...

Embodiment 2

[0042] The hot compress filling composition comprises the following components by mass percentage:

[0043] Iron powder 60%, zinc powder 10%, activated carbon 4%, vermiculite 6%, water 15%, sodium chloride 1%, essential oil 3.9%, super absorbent resin 0.1%.

[0044] A preparation method of a hot compress eye mask comprising the above hot compress filling composition, comprising the following steps:

[0045] 1) Prepare materials according to the following mass percentages: 60% iron powder, 10% zinc powder, 4% activated carbon, 6% vermiculite, 15% water, 1% sodium chloride, 3.9% essential oil, and 0.1% superabsorbent resin.

[0046] 2) Put sodium chloride into water to dilute and dissolve to prepare a diluent for later use. Pour activated carbon and superabsorbent resin into a blender and stir for 10 minutes, then add the diluent to the blender and stir for 3 min, then add zinc powder and stir for 1 min to prepare a mixed liquid;

[0047] 3) Pass the mixed solution through a vib...

Embodiment 3

[0051] The hot compress filling composition comprises the following components by mass percentage:

[0052] Iron powder 20%, zinc powder 40%, activated carbon 10%, vermiculite 15%, water 8%, sodium chloride 2%, essential oil 2%, super absorbent resin 3%.

[0053] A preparation method of a hot compress eye mask comprising the above hot compress filling composition, comprising the following steps:

[0054] 1) Prepare materials according to the following mass percentages: 20% iron powder, 40% zinc powder, 10% activated carbon, 15% vermiculite, 8% water, 2% sodium chloride, 2% essential oil, and 3% superabsorbent resin.

[0055] 2) Put sodium chloride into water to dilute and dissolve to obtain a diluent for later use, pour activated carbon and superabsorbent resin into a blender and stir for 6 minutes, then add the diluent to the blender and stir for 5 minutes, then add zinc powder and stir for 3 minutes to obtain a mixed liquid;

[0056] 3) Pass the mixed solution through a vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com