Electric bus integrated control hardware in-loop test platform and test method

An integrated control and electric bus technology, applied in electrical testing/monitoring, general control system, control/regulation system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0084] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

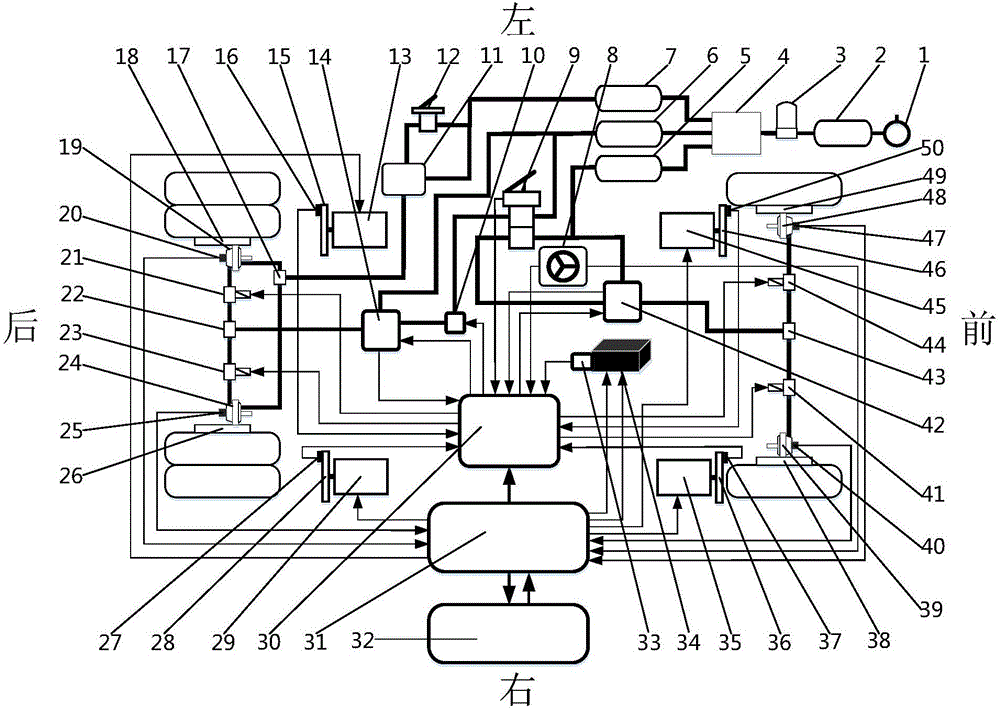

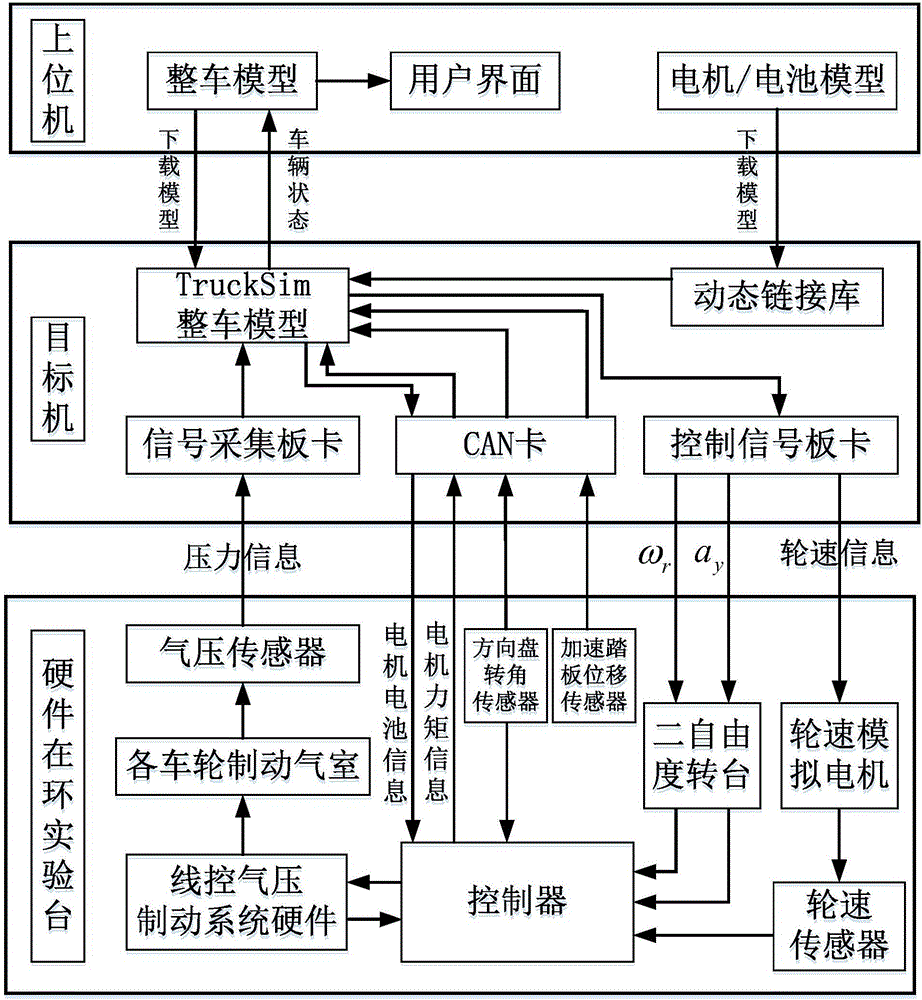

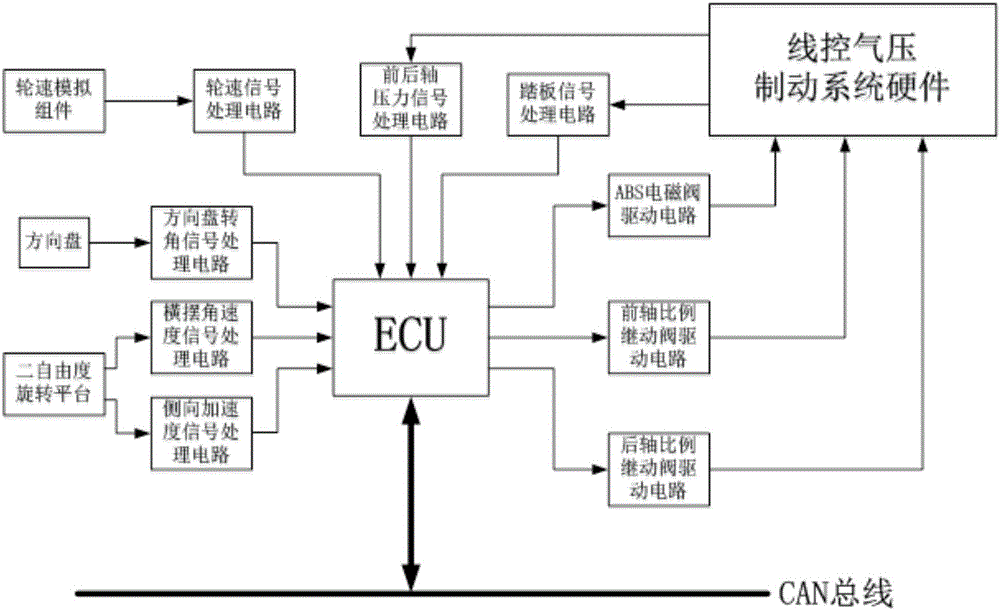

[0085] refer to figure 1 , the present invention discloses a hardware-in-the-loop test platform for integrated control of electric buses. The integrated control of electric buses is based on a control-by-wire pneumatic braking system. component, driving control component, signal simulation component, target machine and host computer.

[0086] The air source assembly includes: air compressor 1, wet air storage tank 2, air dryer 3, four-circuit protection valve 4, front axle air storage tank 5, rear axle air storage tank 6 and parking brake air storage tank 7;

[0087] The control-by-wire pneumatic braking system includes: a controller 30, a master brake valve 9, a front axle proportional relay valve 42, a rear axle proportional relay valve 14, a backup pressure valve 10, a lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com