Sweet corn peeling machine

A sweet corn and peeling machine technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of high breakage rate and low peeling rate, and achieve low breakage rate, high peeling rate and long equipment life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

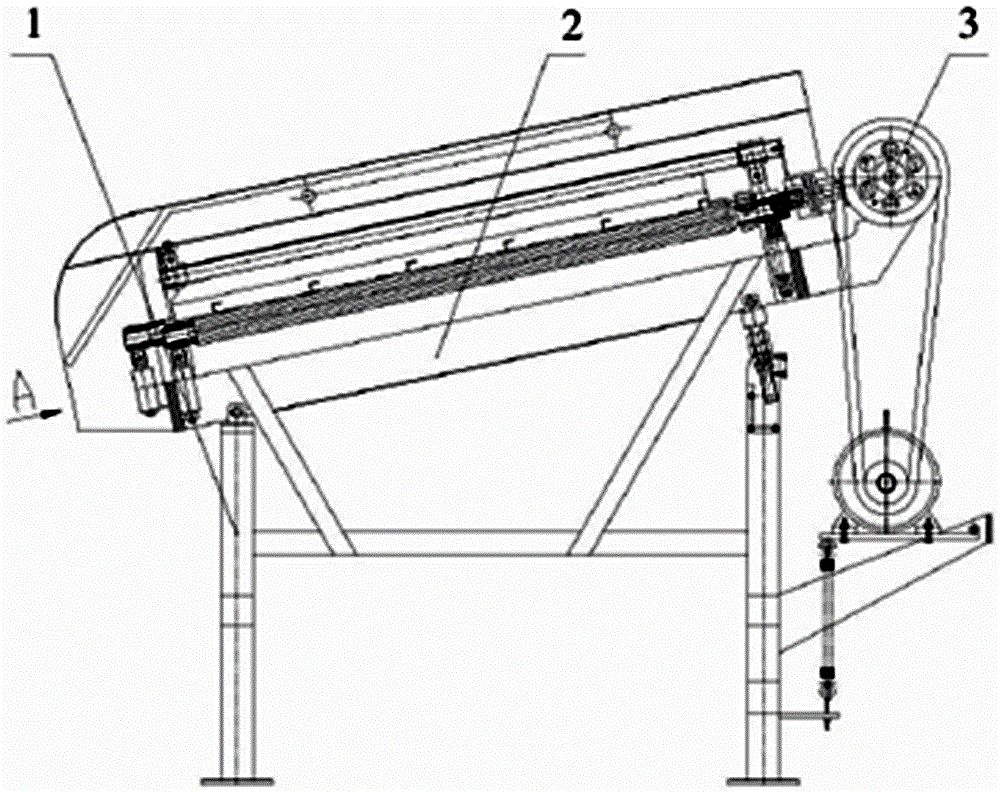

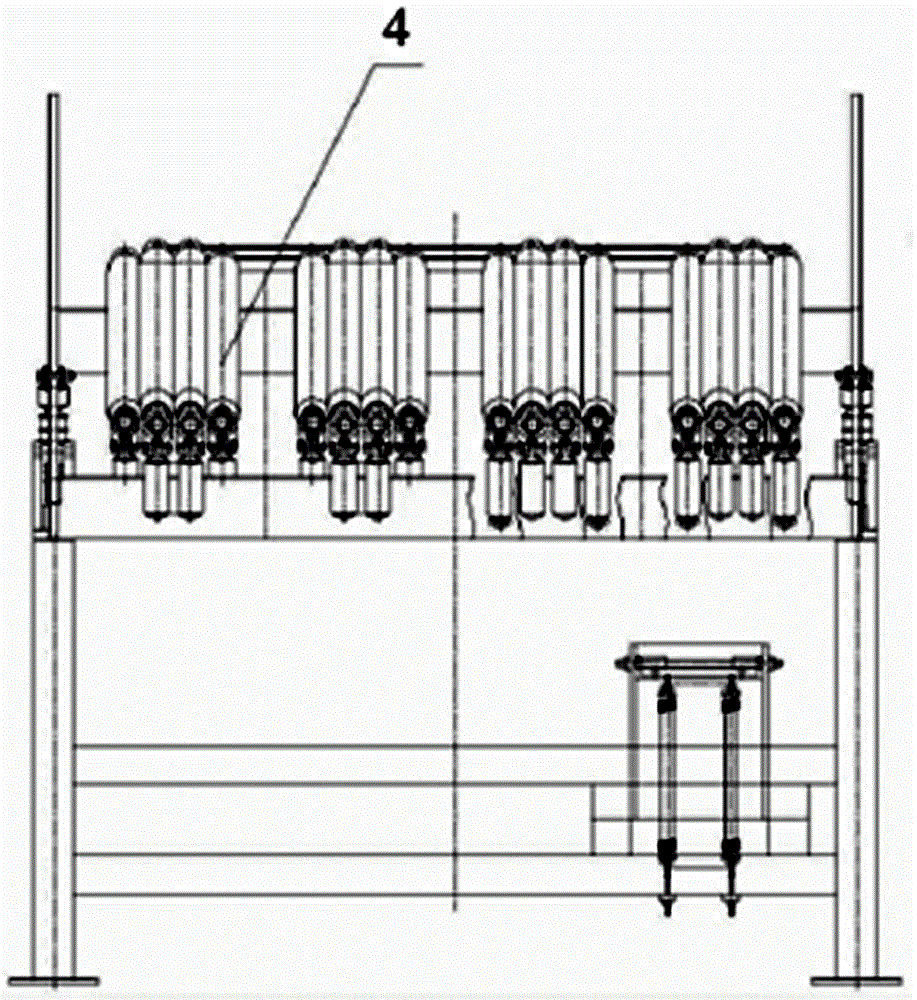

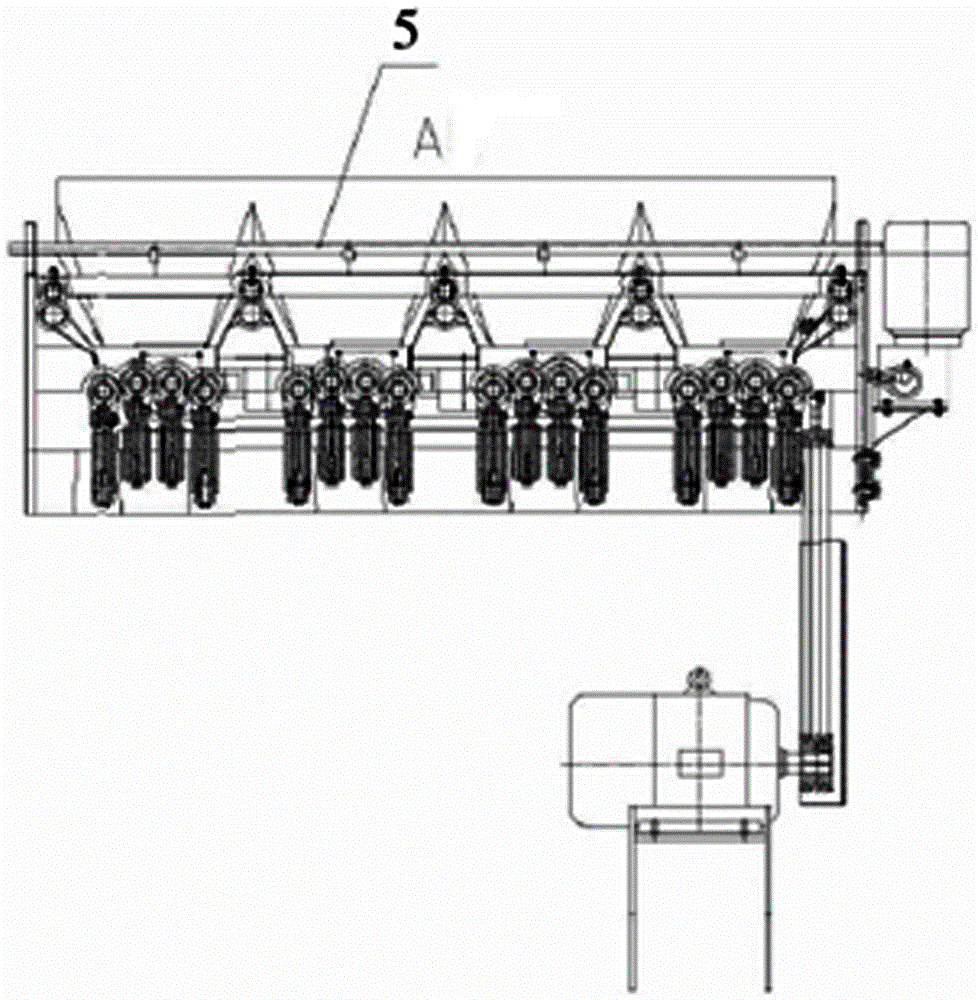

[0012] in figure 1 , 2 , 3 includes: frame 1, housing 2, transmission system 3, roller device 4, water spray device 5. The sweet corn is manually put into the sweet corn peeling. There are four rubber rollers in the roller device 4, which are divided into two groups. The two rubber rollers work together, and each rubber roller is at a certain angle with the ground. The purpose is Sweet corn is easy to move backwards during the peeling process. Among them, the transmission system 3 is composed of a motor, a driving pulley, a belt, and a driven pulley, and the transmission system provides power. Above the sweet corn peeling machine, a water spray device 5 is installed. When the rubber roller rotates, the water spray device starts to spray water. The purpose is to clean the sweet corn slurry stuck on the rubber roller and keep the rubber rotating. The friction between the rollers; reduce the high temperature of the rubber roller due to high-speed operation, protect the rubber rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com