Reaction device for dispersing and blending battery materials

A technology for battery materials and reaction devices, applied in mixers with rotary stirring devices, chemical/physical/physical-chemical stationary reactors, mixers, etc. Inconsistent distribution, difficult batch uniformity control and other problems, to achieve the effect of strong practicability, simple design structure and good work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

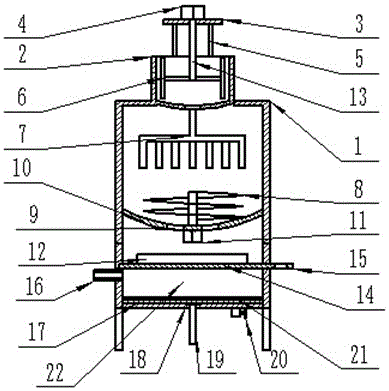

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

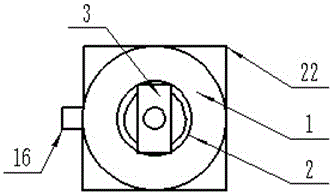

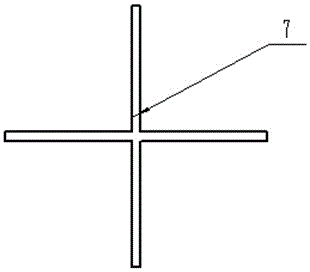

[0017] see Figure 1-3 , a reaction device for dispersing and mixing battery materials, comprising a cylinder 1 and a reaction box 22; the cylinder 1 is provided with a feed cylinder 2, a support rod 5, a motor plate 3, a first motor 4, a rotating shaft 13, a shaped stirring rod 6, cross guide 7, material receiving curved plate 10, spiral stirring plate 8, second motor 11 and annular port 9; The cylinder 2 is convenient for pouring the reaction battery material; there are four support rods 5, which are respectively vertically arranged at the edge of the upper port of the cylinder body 1; the motor plate 3 is horizontally fixed at the upper ends of the four support rods 5 The first motor 4 is affixed to the middle position of the upper end surface of the motor plate 3; the rotating shaft 13 is vertically arranged at the lower middle position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com