An adjustable cutting machine

A cutting machine and adjustable technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of inability to make random adjustments, prone to errors, poor processing quality, etc., and achieve simple structure and low production cost , Improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

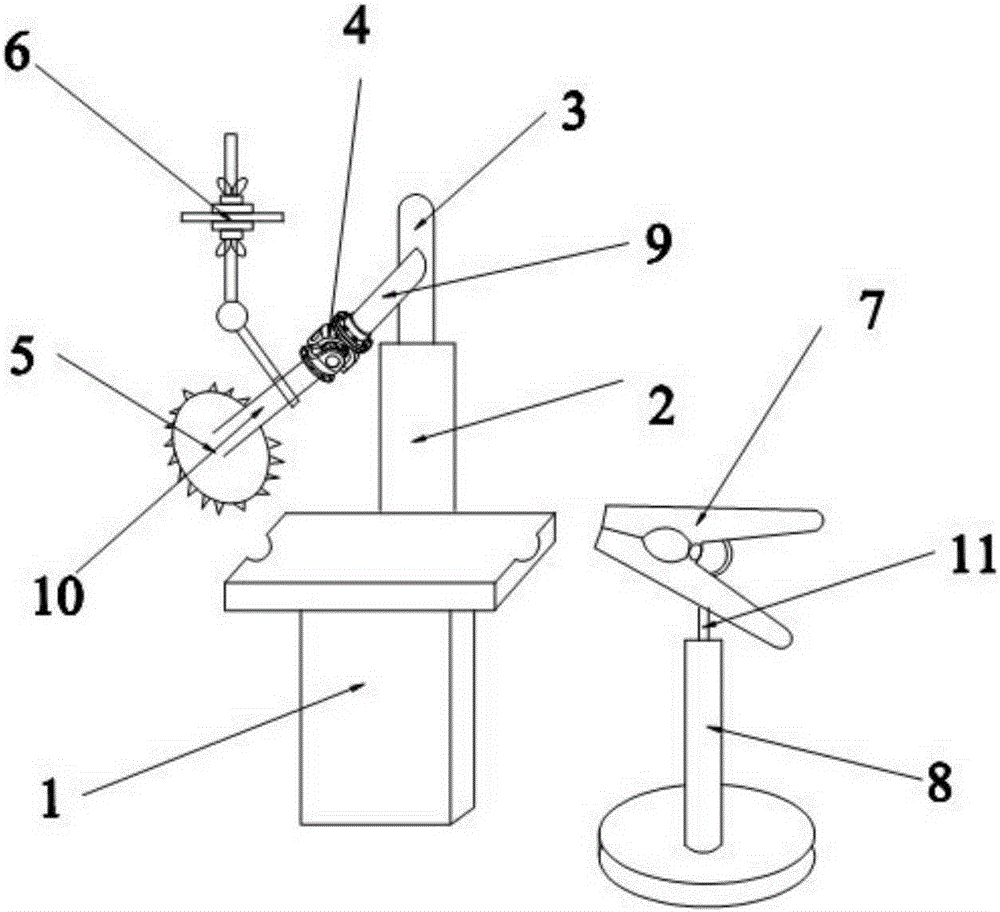

[0016] Such as figure 1 Shown: an adjustable cutting machine, its structure includes: workbench 1, support column 2, rotating shaft 3, universal joint 4, circular saw 5, attitude adjustment device 6, fixing clip 7, cylinder 8, first connecting Rod 9, second connecting rod 10, telescopic rod 11; described support column 2 is fixed on the edge position of workbench 1 by welding, and described rotating shaft 9 is arranged on the center position of the upper end surface of support column 2, and described first The connecting rod 9 is connected with the second connecting rod 10 through the universal joint 4, the circular saw 5 is fixed on the end of the second connecting rod 10 by welding, and the posture adjustment device 6 is fixed on the middle section of the second connecting rod 10 , the fixed clip 7 is connected to the cylinder 8 through the telescopic rod 11, the cylinder 8 is provided with a circular hole for accommodating the telescopic rod 11, and the cross-section of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com