An integrated device for horizontally opposed punching and batch number printing of a roller plate blister packaging machine

A blister packaging, machine-level technology, which is applied to the field of horizontally opposed punching and batch numbering integrated devices for roller-plate blister packaging machines, can solve the problems that restrict the production efficiency, batch numbering and punching stations of the roller-type blister packaging machine. The speed cannot be increased, the inertia force and vibration cannot be overcome, etc., to achieve the effect of eliminating periodic alternating impact loads, saving energy, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

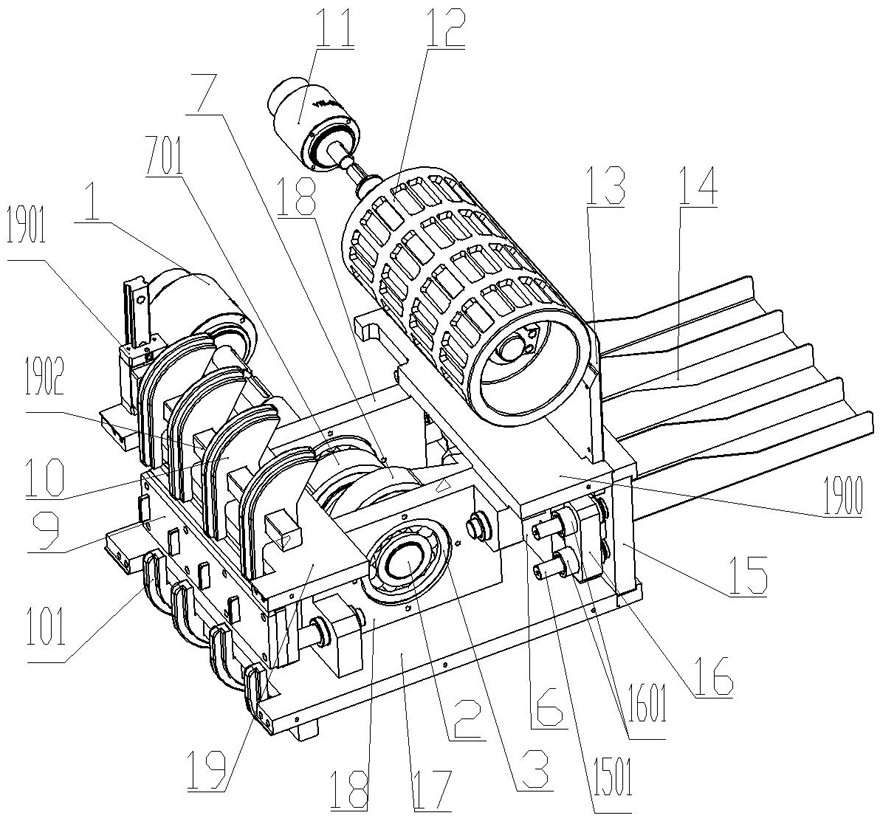

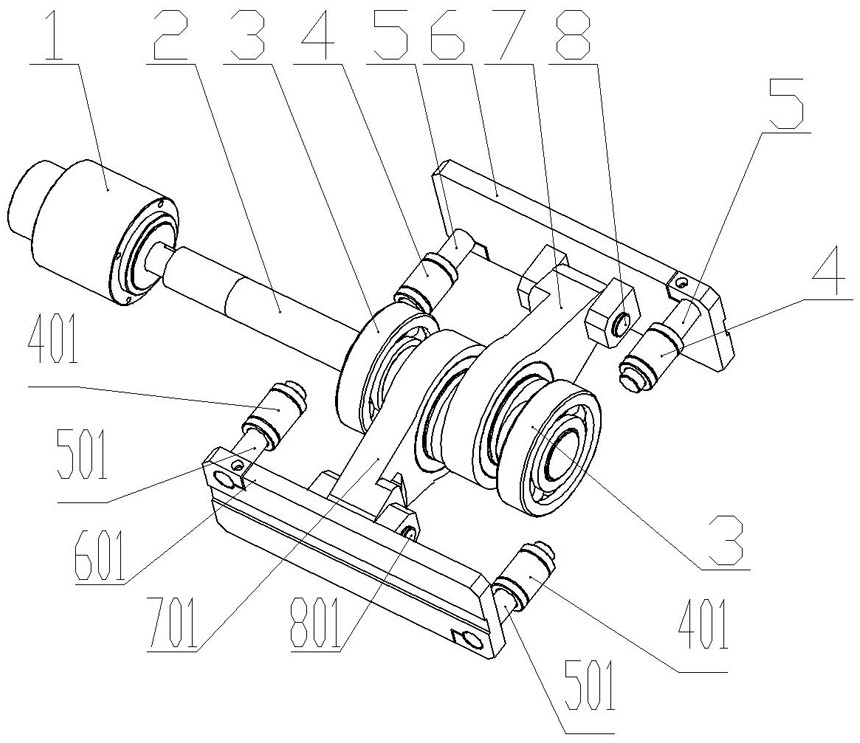

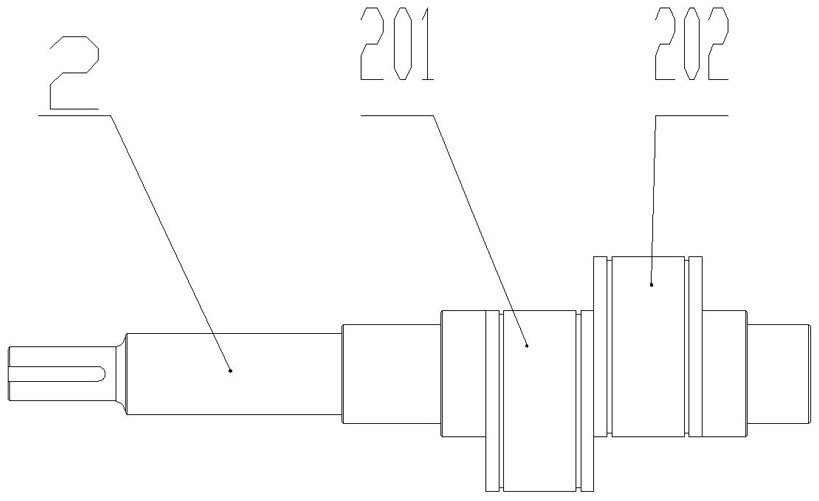

[0014] like Figure 1~Figure 4 As shown, a horizontally opposed punching and batch numbering integrated device for a roller-plate blister packaging machine includes a reducer 1, a base plate 17, and a bearing installation wall plate 18 is installed on the base plate 17, and the bearing installation wall plate 18 passes through the bearing. 3. A double eccentric balance shaft 2 is installed, a marking mechanism is arranged horizontally on the left side of the bearing installation wall plate 18, a punching mechanism is arranged horizontally on the right side of the bearing installation wall plate 18, and a double eccentric wheel balance shaft 2 is provided with The first eccentric wheel 201 and the second eccentric wheel 202 with a phase difference of 180 degrees, an upper pitch adjustment slider 10 is arranged above the marking mechanism, and a lower pitch adjustment slider 10 corresponding to the upper pitch adjustment slider 10 is arranged below the marking mechanism. The pit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com