Isooctane production line

A production line, isooctane technology, applied in the direction of hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of poor control of reflux tank drainage, low working efficiency of raw material buffer tank, and reflux tank cooling efficiency No high problems, to achieve the effect of improving cooling effect, improving flash evaporation effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

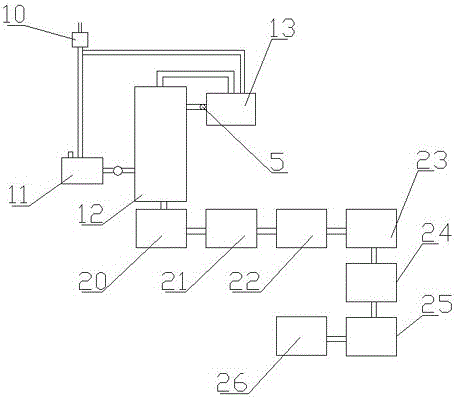

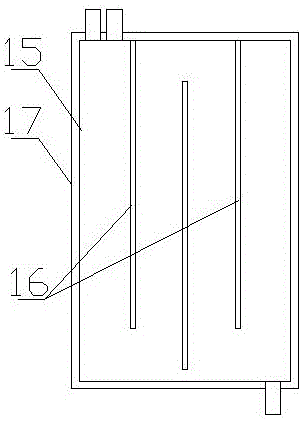

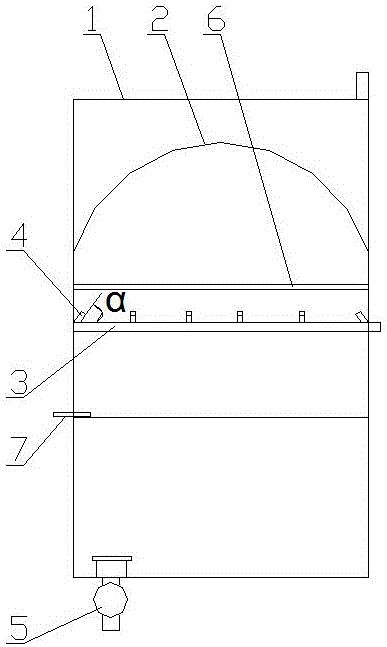

[0013] Such as figure 1 , 2 , 3, 4, and 5, the present invention includes refrigerant pump 10, raw material buffer tank 11, depropanizer 12, reflux tank 13, dehydrator 20, reactor 21, flash tank 22, pickling settling chamber 23, Alkali washing settling chamber 24, de-isobutanizer 25 and de-butanizer 26, raw material buffer tank 11 includes a tank shell 15 and a group of partition plates 16, and the tank shell 15 is respectively provided with an air inlet and a condensing agent inlet and the liquid outlet, a group of partition plates 16 are respectively installed in the tank shell 15, and the tank shell 15 is divided into a plurality of semi-closed cavities, and a guide is provided between the two adjacent partition plates 16. Air plate 18, both sides of air guide plate 18 are welded in the tank shell 15, and the upper and lower ends of the air guide plate 18 are respectively provided with a gap with the inner wall of the tank shell 15, and the tank shell 15 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com