Novel tobacco product prepared from tobacco and cocoa liquor and preparation method thereof

A technology of tobacco products and tobacco, applied in the field of smokeless tobacco, to achieve the effect of large industrial application prospects and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

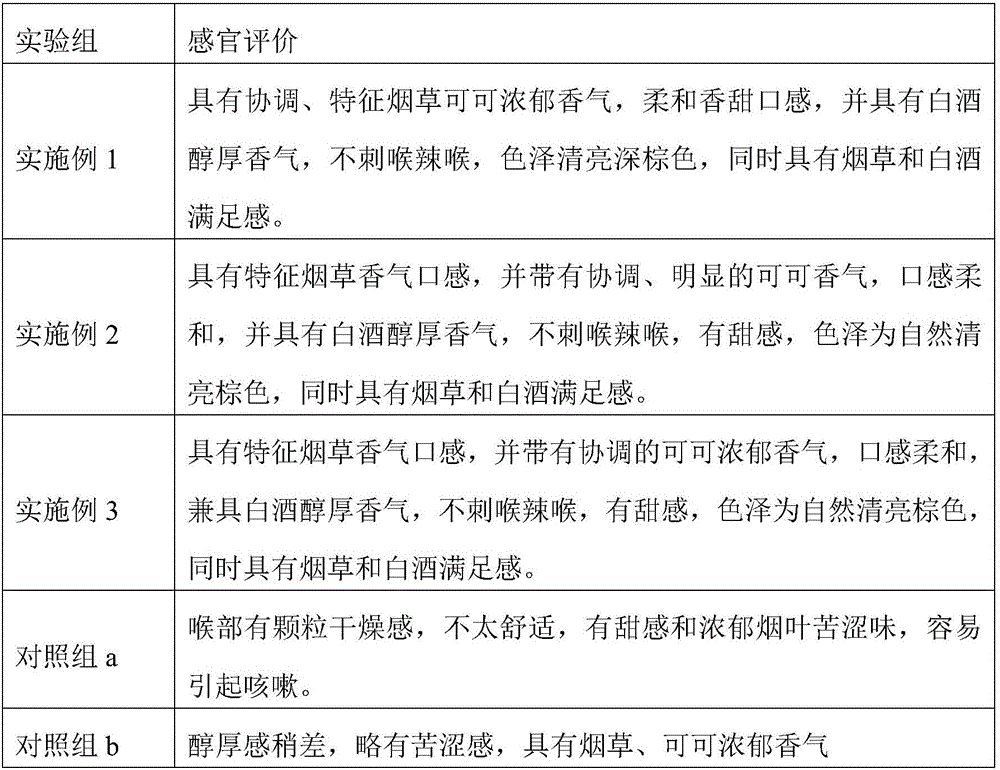

Examples

Embodiment 1

[0024] A new type of tobacco cocoa liquor tobacco product that uses high-quality Yunnan tobacco leaf superfine powder and cocoa bean powder as raw materials, and specifically includes the following steps:

[0025] (1) Preparation of tobacco cocoa fermented wine: mix high-quality Yunnan tobacco leaf powder, cocoa powder, and white sugar at a mass ratio of 1:2:20, add 10 times distilled water, cook at 100°C for 30 minutes, concentrate until the sugar content reaches 160g / L, add The mass ratio of the above-mentioned tobacco powder, cocoa powder and powdered sugar mixture is 0.01% pectinase (food grade, enzyme activity 20000u / g) and 0.01% β-glucosidase (food grade, enzyme activity 10000u / g), Then add appropriate amount of lactic acid and sodium bicarbonate to adjust the pH to 4.2, inoculate active dry yeast with a mixture mass ratio of 0.03%, stir evenly, control the temperature at 25 ℃ for alcohol fermentation for 8 days, until the alcohol content does not change for two consecutive ...

Embodiment 2

[0032] A new tobacco product with tobacco and cocoa liquor, using Zimbabwe high-quality tobacco leaf powder and cocoa bean powder as raw materials, and specifically includes the following steps:

[0033] (1) Preparation of tobacco cocoa fermented wine: mix Zimbabwe high-quality tobacco powder, cocoa powder, and glucose at a mass ratio of 1:1.5:15, add 8 times water, cook at 100°C for 25 minutes, and concentrate until the sugar content reaches 145g / L. Add the above Tobacco powder, cocoa powder and powdered sugar mixture with a mass ratio of 0.01% pectinase (food grade, enzyme activity 10,000 u / g) and 0.005% by mass β-glucosidase (food grade, enzyme activity 5000u / g) , Then add appropriate amount of citric acid and sodium bicarbonate to adjust the pH to 4.8, inoculate the Saccharomyces cerevisiae with a mixture mass ratio of 0.02%, stir evenly, control the temperature at 28 ℃ for alcohol fermentation for 9 days, until the alcohol content does not change for two consecutive days, the...

Embodiment 3

[0040] A new tobacco product for tobacco cocoa liquor, which uses high-quality Yunnan tobacco leaf powder and cocoa powder as raw materials, and specifically includes the following steps:

[0041] (1) Preparation of tobacco cocoa fermented wine: mix high-quality Yunnan tobacco powder, cocoa powder, and xylose at a mass ratio of 1:1:5, add 5 times distilled water, cook at 100°C for 20 minutes, concentrate until the sugar content reaches 100g / L, add The above mixture of tobacco powder, cocoa powder and powdered sugar has a mass ratio of 0.02% pectinase (food grade, enzyme activity 8000u / g) and a mass ratio of 0.01% β-glucosidase (food grade, enzyme activity 1000u / g), and Add appropriate amount of lactic acid and sodium bicarbonate to adjust the pH to 5.0, inoculate the active dry yeast with a mixture mass ratio of 0.01%, stir evenly, control the temperature at 22 ℃ for alcohol fermentation for 10 days, until the alcohol content does not change for more than two consecutive days, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com