Twist setting mechanism

A technology of twist fixing and wire binding, which is applied in the direction of braided fabrics, textiles and papermaking, etc. It can solve the problems of increased power loss of twist fixing devices, affecting the effect of wire harnessing, and multiple thread ends, so as to reduce power loss and improve twist fixing efficiency. , improve the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

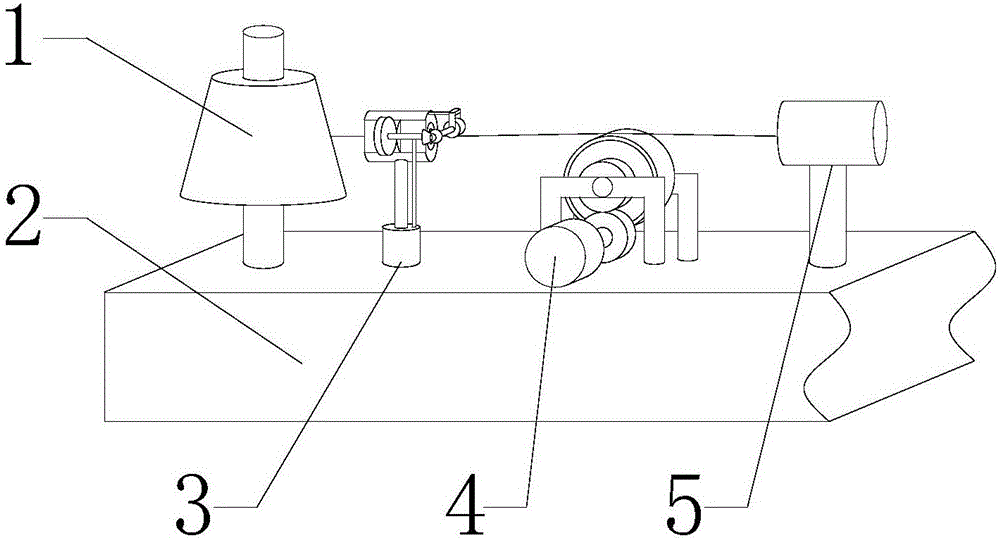

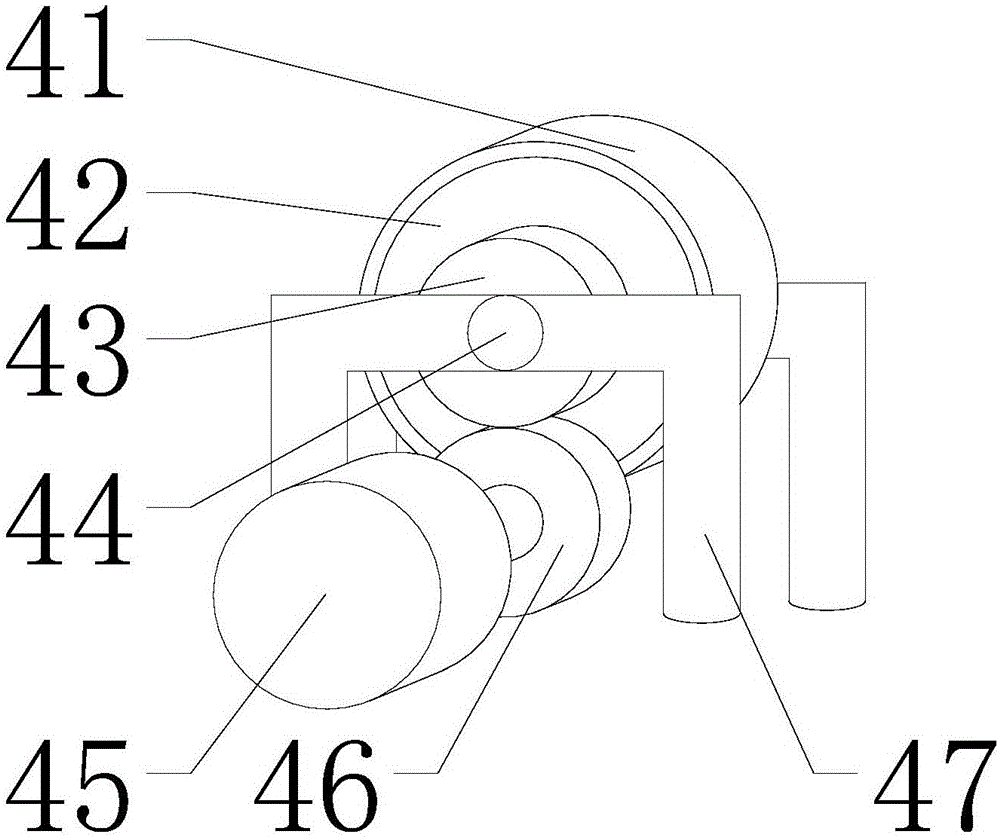

[0024] Specific implementation method: when it is necessary to fix the twist of the fiber thread, the staff first passes the fiber thread on the winding wheel 1 through the wire harness mechanism 3 and the acceleration mechanism 4 to connect with the twist fixing main body 5, and then the staff starts the motor 45 , motor 45 work drives circular gear 2 46 to rotate, because circular gear 1 43 carries out gear engagement with circular gear 2 46, so circular gear 2 46 drives circular gear 1 43 to rotate, and because sliding wheel 42 front ends fix circle Shaped gear one 43, so circular gear one 43 rotates and drives sliding wheel 42 to rotate, and sliding wheel 42 rotates and drives frosted ferrule 41 to rotate, and frosted ferrule 41 rotates and drives fiber thread to move to the right, and realization provides power for fiber thread, this design It has the function of accelerating.

[0025] When the fiber line moves to the right, the fiber line moves to the right to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com