A kind of cast-in-place stair formwork reinforcement structure

A formwork reinforcement and stair technology, which is applied in the direction of formwork/formwork/work frame, building structure, and on-site preparation of building components, which can solve the problem of difficulty in meeting vertical flatness requirements, insufficient leveling operation space, and stability To solve problems such as poor performance, achieve the effect of improving tread leveling operation, improving formwork support method, and strengthening stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

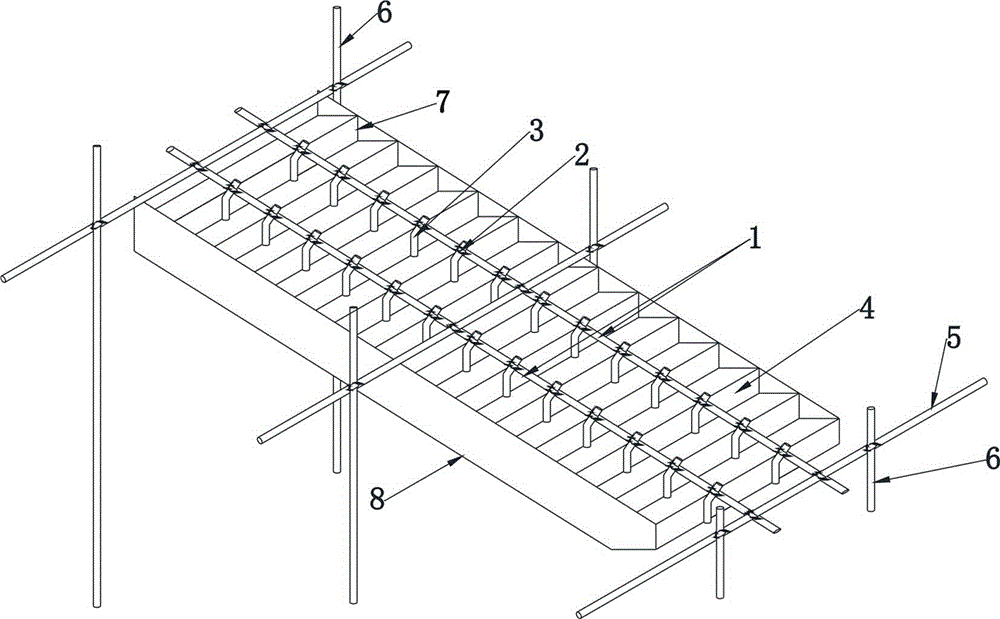

[0018] Such as figure 1 . As shown in 2, a cast-in-place stair formwork reinforcement structure includes longitudinal fixing rods 1 arranged obliquely along the step surface of the building body. There are at least two longitudinal fixing rods 1, preferably two in this embodiment, two Longitudinal fixed rods 1 are arranged on both sides of the stair surface. Fastener 2 is preferably a cross fastener common to construction site leaders.

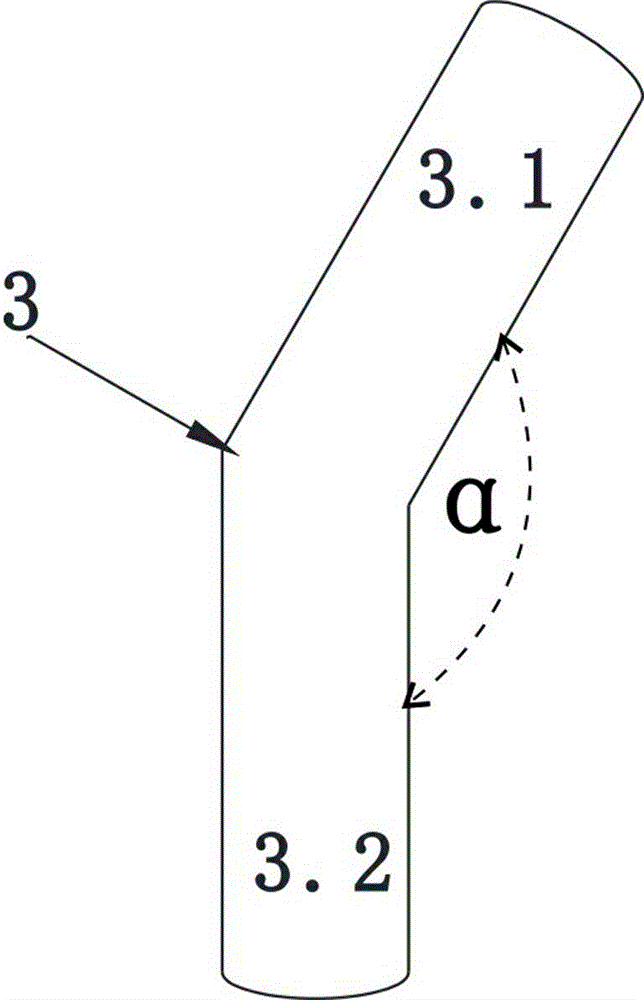

[0019] Each longitudinal fixing rod 1 is fixed with a plurality of reinforcements 3 through cross fasteners 2 at equal intervals from top to bottom, and the reinforcements 3 are against the formwork 4 of the kick surface. Because it is two longitudinal fixed rods 1, the kick surface template 4 on the same stepping surface is pressed against by two reinforcements 3 . The two longitudinal fixing rods are arranged horizontally to each other and are located on the step surface of the building body in an inclined shape. In this way, the two rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com